As long as you have been in a laboratory for studying material properties or have a little understanding of testing equipment, there is an instrument you must have seen, or at least heard of it.

Are you wondering what it is? Yes, It is the universal testing machine (UTM).

The universal testing machine is an indispensable material testing system for you to master material properties, develop new products, and inspect the product quality. Its application is very expansive, so it has become the most commonly used equipment among all testing instruments. If you can find and read this blog post, I guess you may be very interested in the knowledge of UTMs, or now your laboratory requires such a testing machine. But in the face of so many different styles of universal testing machines in the market, you may be confused about how to judge them, which model to buy, where to buy one, etc.

It doesn’t matter. Now we will introduce this instrument in detail and take you to understand it more deeply.

What’s A Universal Testing Machine (UTM)?

UTM is short for Universal Testing Machine, also called the UTM machine, materials testing machine or universal tester. It is mainly intended to test the tensile strength and compressive strength of various specimens.

The UTM is a new generation of mechanical testing equipment integrating processor control, automatic measurement, data acquisition, screen display, and test result printing.

From the first word “universal” of its name, we can instinctively judge that it is not a single-function device but versatile equipment, because it is capable of conducting tensile, compression, peel, bend, puncture, tear, shear tests on a variety of materials, semi-products and finished products as per ISO, ASTM, DIN, JIS etc. international standards.

Among a series of test items, the tensile test is performed relatively often with this mechanical testing system, so we also habitually call this instrument a universal tensile testing machine.

The above test types sound like they are totally different from each other. How can a machine make it? It is very simple. We only need to replace the corresponding fixtures and grips for different test items.

What Are the Core Components of a Material Testing Machine?

Load Frame

Made of high-strength metal, and It generally has either a single column or double columns to support the load. You can freely choose one of the two according to the load-carrying range of your test samples.

Controller

It is a microprocessor whose function is similar to the brain of a machine, featuring fast computing speed, excellent processing performance to ensure the control accuracy of the machine, and efficient data analysis.

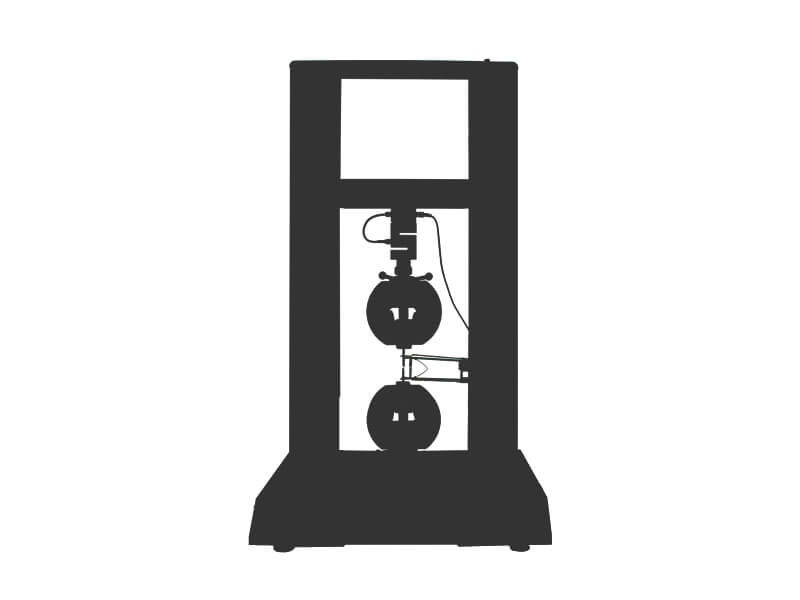

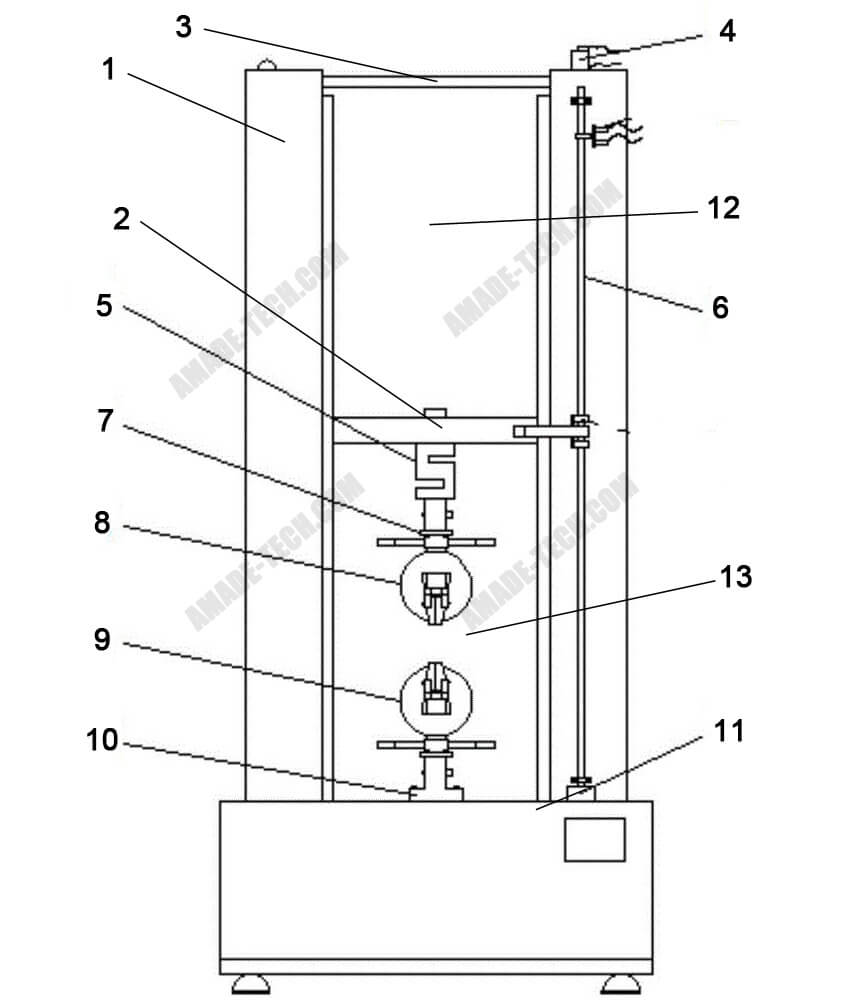

Schematic Diagram of UTM

1.Load frame

2.Movable cross head

3.Upper cross head

4.Displacement encoder

5.Load cell

6.Ball screw

7.Universal spindle coupling

8.Upper clamp

9.Lower clamp

10.Flange base

11.Table top

12.Space for tensile test

13.Space for compression test

Load Cell

It is also called as the force transducer. The load cell is actually an apparatus that converts the mass signal into a measurable electrical signal to measure the force acting on the specimen during the test.

Load Cell

Servo Motor

Drive System

It includes a motor and a transmission. Commonly used motors include servo motors, stepping motors and inverter motors. Precision ball screws are used to ensure high transmission efficiency and transmission accuracy.

Clamping Apparatus

A complete pair of grips consist of an upper moveable grip and a lower stationary grip. For compression tests, they are platens instead of grips. One material testing system can be configured with up to dozens of different interchangeable grips and fixtures to achieve various tests.

Clamping Apparatus

Displacement Encoder

It is used to measure the displacement between two opposite fixtures during the test.

Movable Cross Head

It is capable of moving up and down at a predetermined constant rate under control.

Extensometer

It is an auxiliary apparatus to help in measuring the elongation of the specimen accurately.

Output Device

It is used to display the real-time parameters and test results. A digital color screen is attached to the machine to achieve this function.

Now, more and more testing machines support connection with computers, whether they are laptops or desktops, so that you can directly view the test results in real time on a computer screen. Test results can be printed on paper.

How Does a Universal Testing Machine Work?

A specimen with a specified size is clamped in the grips of the machine. The upper movable clamp stretches the specimen upwards at a constant speed until the rupture occurs. When the grip begins to apply an increasing force on the specimen, the real-time force value and the relative displacement of the upper and lower clamps are respectively collected by the force transducer and the photoelectric displacement encoder, analyzed and calculated by the processor, and presented in the form of curves and numbers on the display for viewing and printing.

An extensometer is required if you want to determine the change in gauge length of the specimen during the test.

Note: When conducting the compression test, the direction of movement of the movable crosshead is opposite to that of performing a tensile test.

How to Select a Universal Tensile Testing Machine?

If you haven’t been in touch with UTM before, facing so many different types of machines, you may be confused about which one to buy that can meet your testing needs without causing performance waste and costing extra money.

In fact, it is easy, as long as you have basic knowledge of the tensile testing system. According to your own samples to be tested and test requirements, you can easily choose a satisfactory tensile machine.

First of all, We will introduce you the types of universal testing machines.

Single-column Tensile Testing Machine

The single-column type has only one column to bear the force applied to the sample in the test. It is also referred to as the table-top material testing machine, as it is relatively small in size, space-saving, and lightweight.

Generally, the maximum allowable capacity of a single-column tensile device is 5 kN, and the maximum measurable capacity that the user can select includes 10 N, 20 N, 50 N, 100 N, 200N, 500 N, 1 kN, 2 kN, 5 kN. The larger the measuring range of the universal tester, the higher the price.

Generally, the single-column tensile tester machine is more suitable for samples with low tension or compression, such as Fabric film, tape, paper, sponge, etc.

Dual-column Tensile Testing Machine

The dual-column type features two parallel metal columns sitting on the base of the machine, and the tops are connected by a beam. The height of the double-column machine varies from one meter to several meters in compliance with different applications.

The solid structure and body enable it to have a robust load-bearing capacity to handle various samples regardless of whether they are strong or weak. Generally, for the twin-column electromechanical tensile test machine, the maximum range that the user can select includes 10 N, 20 N, 50 N, 100 N, 200 N, 500 N, 1 kN, 2 kN, 5 kN, 10 kN, 20 kN, 50 kN, 100 kN and more.

Its applicable specimens include rubber, plastic, shoes, leather, metal and so on.

Manual Tensile Testing Machine

The manual tensile machine does not require additional power. You can operate the hand wheel or lever handle to drive the fixture to pull the specimen during the test.

The manual testing machine is only suitable for samples that have no extremely high requirements for the test capacity.

It is generally only used to test the tensile force, not the displacement. The most typical manual tensile machine we commonly use is the button pull tensile machine.

Electromechanical Tensile Testing Machine

This type of testing machine is the mainstream product of today’s universal material testing family. We often use a servo motor as a driver and a lead screw and a nut as an executive element to realize the accurate speed control of the moving crosshead of the testing machine.

It is simple to operate and does not have high requirements for operators. The test stroke can be customized as needed. Although the control mode is relatively single, there is only one-speed control mode, but its control accuracy and control range is very high and wide. Take the tensile testing machine from AMADE TECH as an example. Its speed adjustment range can reach 0.001 mm / min ~ 1000 mm / min, with step-less speed regulation. Control accuracy can attain 0.5.

The electronic tensile testing machine has great configuration flexibility. It can be equipped with sensors, fixtures and accessories of different tonnages to achieve multiple functions in one machine, such as tension, compression, bending, shearing, peeling, tearing, coefficient of friction, and torsion tests.

Manual Hydraulic Tensile Testing Machine

This type of testing machine is the “ancestor” of the universal testing machine family. It has a long history, with low price and large tonnage. As the name suggests, manual hydraulic pressure shows that it is an open-loop control with poor performance, and the operation process is completely dependent on the operator’s operating level.

In addition, its mechanical structure and hydraulic loading principle determine its loading speed. The test stroke is minor. At present, the smallest capacity of this type of testing machine is 50 kN, so its measurement accuracy for small load is very low, and the extension configuration ability is very poor. It is generally only used for structural component tests or simple material performance tests, such as disconnection tests of connecting components, Tensile strength tests of steel bars.

Electrohydraulic Servo Universal Material Testing Machine

This kind of material testing machine is a kind of equipment with better performance at present. Because it adopts electro-hydraulic servo control technology, it can realize the closed-loop control of force, displacement, deformation and has good control performance. At present, it is widely used in metal, building materials, composite materials, etc., where constant stress, constant strain and creep test are required. However, due to the limitation of the oil source flow rate, its test speed is low.

In order to increase the rigidity of the system and ensure the stable operation of the closed-loop control, the stroke of this type of testing machine is small. The operation is complicated, and it is difficult to expand the configuration. There are few capacities below 10 kN, so it is not suitable for testing plastic and rubber materials.

Digital Display Tensile Testing Machine

The digital display type tensile testing machine is also called microcomputer type tensile testing machine. The machine has a built-in microprocessor for data calculations and statistics.

There is a particular load cell and displacement sensor in the machine to collect the force applied to the sample and the stretched length of the sample during the test. The test data obtained can be drawn on a graph to produce a tension/displacement curve and directly displayed on an LCD.

The digital display tensile tester has advantages of high test accuracy, adjustable test speed, interchangeable grips, and convenient operation. It is often used for material performance testing and factory quality control. The microcomputer tensile tester is one of the mainstream types of tensile testing machines in the market.

Computerized Tensile Testing Machine

The computerized universal testing machine is also one of the most common types of tensile machines in real-world applications. It adopts a digital control system with high precision to enable fast response and convenient operation.

The machine is fitted with the PID closed-loop control and multi-closed-loop non-impact switching to provide the most accurate and repeatable test. The control unit of the tensile machine is connected to the computer via Ethernet. All data in the test can be collected, analyzed, calculated, and output by the computer.

You can set and modify various parameters on the computer screen and view real-time test data and curve status. The final data is calculated and processed by the software and can be printed out in the form of reports. The computerized tensile testing machine is often used in scientific research units, testing institutions, factory laboratories, etc.

Variable Frequency controlled Tensile Testing Machine

It uses a frequency conversion motor control system. The tension and compression speed of the tensile machine is controlled by a frequency converter. The tensile testing machine with a variable frequency control system has a low-cost advantage, but the control accuracy is not high.

Stepper Motor Controlled Tensile Testing Machine

The stepper motor controller is an electronic device that can send out uniform pulse signals. After the signal sent by it enters the stepper motor driver, it will be converted by the driver into the strong current signal required by the stepper motor to drive the stepper motor to run.

The stepper motor controller can accurately control the stepper motor to rotate through every angle. What the driver receives is a pulse signal, and every time it receives a pulse, the driver will give the motor a pulse to make the motor rotate through a fixed angle.

The stepping system has both cost advantages and better control accuracy, making it an ideal control system for tensile machines.

Servo Motor controlled Tensile Testing Machine

A servo motor controller is used to control a servo motor. Its function is similar to that of a frequency converter acting on an ordinary AC motor. It is a part of the servo system and is mainly used in high-precision positioning systems.

Generally, the servo motor is controlled in three ways: position, speed, and torque to achieve the high-precision positioning of the transmission system. The servo system has exceptional control accuracy and is the highest-end control system in the tensile machine. It adopts intelligent feedback operation, which can realize constant speed test, loop test, programming test, etc.

If you have high requirements for the precision and stability of the tensile machine, then the servo system is your first choice.

Rubber Tensile Testing Machine

The rubber tensile testing machine is intended to determine various mechanical characteristics of rubber, such as tensile strength, elongation. Due to the relatively large elongation of rubber or elastomer, an extensometer device is required. At the same time, the design of the holding device should consider the characteristics of the rubber and not slip. It can be equipped with O-ring fixtures, fixtures for the tire industry, etc.

Plastic Tensile Testing Machine

A twin-column tensile testing system and corresponding grips are configured to test on metal materials like steel bars. Metallic materials have low tensile strength and low elongation, so a metal extensometer is needed.

Fabric Tensile Strength Tester

The textile industry needs it to determine the peeling, puncture, tearing, and single yarn stretching properties of fabrics. The fixtures and software are relatively special.

Leather Tensile Testing Machine

The leather tensile testing machine is mainly used in shoemaking and clothing industries. Leather needs to be tested for tensile strength, tear strength, etc. The test items are relatively simple.

Paper Tensile Strength Tester & Paper Board Compression Testing Machine & Box Compression Tester

Paper and paparboard need to be tested for tensile strength, and ring compression strength, vertical compression, paper board flat compression, paper board edge compression, peel strength, box compression test etc.

Please read more about different test items in the next chapter

What Test Items Can a Universal Tensile Testing Machine Perform?

Plastic Film Tensile Strength Test

The film tensile strength test is one of the most basic tests to determine the mechanical properties of plastic films. You need to mount the plastic film of the specified size in the upper and lower clamps of the universal machine, and let the upper clamp pull the sample at a constant speed until it breaks.

The tensile strength is the force per unit cross-sectional area of the sample when it is pulled off. Because the elongation of the film is substantial, if you need to measure elongation accurately, an additional auxiliary extensometer is required to help complete the test.

Plastic Film Puncture Resistance Test

The film puncture resistance test is to determine the puncture resistance of the plastic film. We will provide you with special jigs. Before the test, you need to fix the sample horizontally in the cylindrical fastening device of the material testing system.

After starting the machine, the puncture needle gripped in the upper clamp moves downward to pierce the center of the sample vertically at a constant velocity. The load and puncture elongation of the sample during the test will be measured.

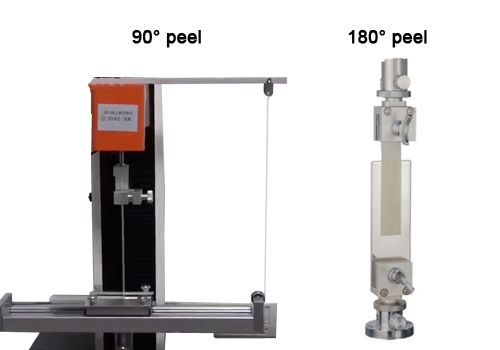

Adhesive Tape Peel Test

The tape peel test is to determine the adhesion strength of various tapes. Based on different tensile angles, this test is generally divided into the 180° peel test and the 90° peel test. Both require the sample to be pasted on a steel plate according to the specified method.

When doing a 180-degree peel test, you need to clamp the short side of the steel plate vertically with the lower clamp of the machine, and then clamp the free end of the specimen vertically with the upper clamp. The tensile direction and the bonding direction of the sample are maintained at 180 degrees. The upper clamp pulls the sample at a constant speed to separate it from the steel plate.

When doing the 90-degree peel test, we will prepare an additional auxiliary apparatus for you. It is a rectangular metal part with grooves, which is placed horizontally and firmly fixed in the clamp area of the base. This device acts as a lower clamp to hold the steel plate and enable the steel plate to slide based on a special mechanism, so that the sample is always kept at 90° with the horizontal plane of the steel plate during the peeling process.

Wire Terminal Pull Test (Crimp Pull Test)

The wire terminal pull test is to determine the pull-out force of the wire harness terminal. We can configure various fixtures for you according to the characteristics of your samples. You need to clamp the end without the terminal in the lower jaws and hold the terminal in the upper grip.

After the machine is started, the terminal is pulled up until it falls off. The maximum tensile force will be recorded. It is easy to operate and has high measurement accuracy. It is an indispensable test item for research, development and quality control of the wire harness and electronic industries.

Three-point Flexural Test

The three-point flexural test is a test method to determine the mechanical properties of metal or plastic bending. The operator places the specimen on two supporting points at a certain distance. The upper fixture applies a downward load to the specimen at the midpoint of the two supporting points. When the three contact points on the specimen form two equal torques, a three-point bending occurs. The specimen will fracture at the midpoint.

Spring Compression / Tensile Test

The spring compression / tensile test is to test the spring stiffness coefficient, spring force, displacement load, load displacement, and other mechanical properties. When you perform the pressure test, the cylindrical specimen is erected and placed in a designated area. The circular platen moves downward and gradually applies pressure to the specimen from above at a constant rate. When conducting the spring tensile test, another set of grips to pull up the spring sample in the opposite direction will be configured for you.

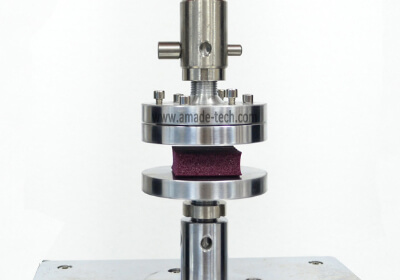

Sponge Compression Test

This sponge compression test is to determine the concave hardness of porous elastic materials. It can accurately measure the indentation hardness of sponge, foam and other materials.

The operator needs to place the sample between the upper and lower platens. After the machine is started, the upper platen compresses down for a specific size to the specified concavity at a specified speed. During the compression process, the load cell on upper assembly will feedback the sensed pressure to the controller for processing and display to measure the indentation hardness of sponge, foam, and other materials.

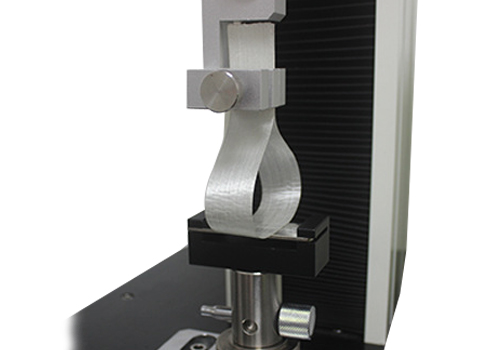

Sole Vamp Tensile Test

The sole vamp tensile test is to determine the peel strength between the sole and the upper to evaluate the quality of the shoe. Before the test, you need to grip the sole and upper in the upper and lower clamps of the tensile machine. After the machine is started, the upper clamp pulls up the sample at a constant speed. You will grasp how much force you need to apply to separate the sole and the upper completely. The pulling force exerted by the clamp during the lifting process will be transmitted to the processor in real time and displayed on the screen.

Line Tensile Test

The line tensile test is mainly to determine the tensile strength of various lines and wires, including fishing lines, copper wires, wool, etc.

We will configure unique fixtures for you, so that the sample can be firmly secured on the machine to ensure that the sample does not slip off during the test.

The above test items are some of the most basic test items that AMADE TECH’s universal material testing machines can perform. Because the application range of the universal testing machine is too wide, it is impossible for us to list all the test items here.

If you need to do other more testings by means of a universal tensile testing machine, please feel free to contact us to acquire more details and price. Unique grips will be tailored to your specimens and testing requirements.

Universal Tensile Testing Machine Price

The price of a universal tensile testing machine varies widely, depending on the type and configuration. I can’t give you a fixed answer here, but you can first figure out what factors affect the price, which will help you when choosing the right machine.

Generally, single-column tensile testing machines are cheaper than double-column tensile testing machines for the same brand. Because the single-column tensile tester has lower bearing capacity than the double-column tensile tester, its manufacturing cost is also lower than that of the double-column tensile machine.

In terms of driving motors, the tensile machine using a servo motor is more expensive than the tensile machine using a stepper motor, and the tensile machine using a stepper motor is more expensive than the tensile machine using a frequency conversion motor.

From the perspective of the difference in control methods, the tensile testing machine controlled by computer software and monitor is more expensive than the tensile testing machine controlled by the electronic color screen.

If you want to know more details about the price of the tensile machine, don’t hesitate to get in touch with us by email: [email protected]. Our professional sales staff will offer a reasonable quotation according to the different testing needs of customers.

Where to Buy Universal Testing Machines?

There are many universal testing machine suppliers in the market. Some of them have very low prices, but the quality is poor, and some of them are of good quality, but the prices are too high to afford. Both of these are suppliers that professional purchasers try to avoid.

Is there a supplier of universal tensile testing machines with very reliable quality and reasonable prices? AMADE TECH is a tensile testing machine manufacturer you can consider, because here you may be able to find the best balance between quality and price.

AMADE TECH is a manufacturer and supplier of testing equipment from China. We have many years of experience in instrument manufacturing, featuring experienced workers, mature technical teams, and after-sales personnel. Our products have been exported to dozens of countries and regions. Customers have given us a high evaluation.

Reliable Quality

Quality is the foundation of a company’s survival. Our universal testing machine, from product design, material selection, manufacturing, and assembly, all steps are based on the highest standards of industrial manufacturing. In the production process, we strive for perfection in every detail.

In order to ensure the ultra-high test accuracy and stability of the machine, we have selected world-renowned brands as component suppliers, such as servo motors from Panasonic as drive motors and force transducers from Transcell.

Flexible & Rich Configurations

AMADE TECH has focused on tensile machines for many years. We can provide dozens of different tensile and compression jigs to meet different testing needs.

You only need to tell us your test items, sample types or standards to follow, and our sales staff will select suitable equipment and holding devices for you according to your situation, saving you a lot of time and energy.

Affordable Price

AMADE TECH is located in China. As the largest and most comprehensive manufacturing base in the world, we have advantages in labor cost, raw material cost, and policy support. Together, these advantages have brought us product price advantages, making our products more competitive in the market, and these advantages can benefit all purchasers around the world.

If you are looking for a universal testing machine, please feel free to reach us, or directly leave an enquiry in the form below.