IP Testing Equipment is short for ingress protection testing equipment. They consist of a series of devices used to assess the extent of protection of persons against access to hazardous parts inside the enclosure and protection of the equipment inside the enclosure against ingress of solid foreign objects and (or) against ingress of water.

The IP code indicates the degree of protection provided by an enclosure. Different letters and numerals following the “IP” represent different protection levels. The access probes, object probes, dust chamber and waterproof test equipment, constitute the IP testing equipment. The probes are used to test the protection ability of persons or equipment indicated by the numerals and additional letters in the first and third positions after the “IP”. The dust chamber is suitable for testing the dust-proof ability of the enclosure indicated by the first numeral. The waterproof test equipment is used to test the waterproof performance of the enclosure indicated by the second numeral.

Amade Tech is an Ingress protection test equipment manufacturer and supplier in China. We are available to supply a complete set of IP test equipment in compliance with IEC 60529, ISO 20653 and DIN 40050-9. The following content will help you learn more about test equipment and IP testing.

IP1X Access Probe A – Test Sphere

- The rigid sphere of 50 mm in diameter is made of metal.

- The handle of 100 mm in length and 10 mm in diameter is made of insulating material.

- Fitted with a guard of 45 mm in diameter and 4 mm in thickness.

- Configured with a self-measuring scale for the test force of 50 N if required.

IP2X Access Probe B – Jointed Test Finger

- Made of metal and insulating material.

- Simulation of a human finger with 2 joints.

- Finger length of 80 mm and diameter of 12 mm.

- Both joints can move in the same plane and in the same direction through an angle of 90°.

- 100 mm from the stop face to the guard of 75 mm in diameter and (5±0.5) mm in thickness.

- Configured with a self-measuring scale for the test force of 10 N if required.

IP2X Object Probe Sphere

- Made of metal (for sphere) and insulating material (for handle and guard).

- Rigid sphere of 12.5 mm in diameter, handle of 100 mm in length and 4 mm in diameter.

- Guard of 10 mm in diameter and 4 mm in thickness.

- Configured with a self-measuring scale for the test force of 30 N if required.

- Complies with DIN 40050-9.

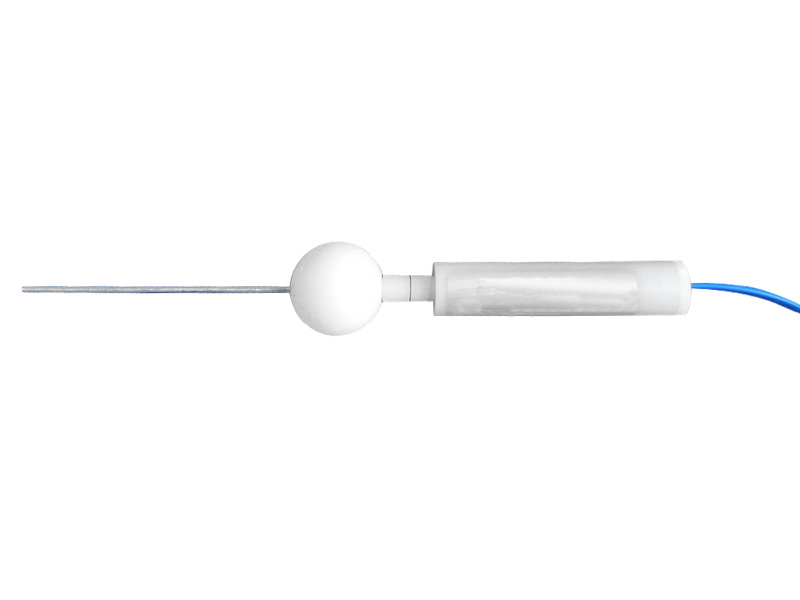

IP3X Access Probe C – Test Rod

- Made up of the rigid test rod, sphere and handle in a straight line.

- The metal rod is 100 mm in length and 2.5 mm in diameter, and the rod edges are without burrs.

- The material of the sphere of 35 mm in diameter and the handle of 100 mm in length and 10 mm in diameter is the insulating material.

- Configured with a self-measuring scale for the test force of 3 N if required.

IP4X Access Probe D – Test Wire

- A rigid test wire and a handle are arranged on either side of the 35 mm diameter sphere to form a straight line.

- The wire edges are free from burrs.

- The rigid wire of 1.0 mm in diameter and 100 mm in length.

- The handle of 10 mm in diameter and 100 mm in length is an insulating material.

- Configured with a self-measuring scale for the test force of 1 N if required.

IP5X/IP6X & IP5KX/IP6KX Dust Chamber

- Used for dust-protected and dust-tight testing.

- The inner chamber surface is mirror stainless steel to prevent dust adhesion.

- A funnel-shaped bottom inside the chamber to facilitate collecting the falling dust for reuse.

- A powder circulation pump keeps the powder in suspension throughout the test.

- A piece of glass and dust wiper is equipped for better observation from the outside during the test.

- Fitted with a heating apparatus to heat the chamber to prevent dust from caking during testing.

- The temperature and humidity in the chamber are collected in real-time.

- Test temperature and airflow rate are adjustable to achieve uniform distribution of the dust.

- Configured with a set of the vacuum system for the sample if required.

- The sample is allowed to be energized if required.

- Fitted with a PLC and 7” touch screen for automatic control, parameter settings and real-time data presentation.

- The chamber size is tailored to practical requirements.

IPX1 & IPX2 Drip Test Equipment

- For assessing the protection against vertically falling water drops.

- Box-type drip test chamber & open-type drip apparatus available.

- Artificial raindrops are provided over the specimen by dripping needles spaced 20 mm apart from each other.

- Water flow rate of (1 + 0.5) mm/min for IPX1 & (3 + 0.5) mm/min for IPX2.

- The turntable is rotatable and inclinable by 15 degrees.

- Fitted with a touch screen and PLC for data input, display, and automatic control.

IPX3/4/4K Water Spraying & Splashing Test Equipment

- For determining the protection against splash water and water spray.

- Box-type spray/splash test chamber & open-type spray/splash test apparatus available.

- Allows configuration of oscillating tubes of different radii.

- The oscillating tube can spray ±60° from vertical for IPX3 testing and spray ± 180° from vertical for IPX4 testing.

- The water flow rate is adjustable.

- The turntable is rotatable.

- Fitted with a touch screen and PLC for data input, display, and automatic control.

IPX3/IPX4 Hand-held Spray Nozzle

- Used for carrying out the IPX/4 water ingress protection test on specimens which can’t be thoroughly wet using the swivel tube.

- The spray nozzle is made of brass and 304 stainless steel.

- Full manual control enables you to wet every part of the enclosure under test.

- The nozzle contains 121 holes with a diameter of 0.5 mm.

- The required pressure is from 50 kPa to 150 kPa.

- Comes with a pressure gauge and ball valve, and an electronic flowmeter is allowed to be added if required.

- The shield shall be in place for the IPX3 test and be removed from the spherical area for the IPX4 test.

IPX5/6/6K Water Jetting Test Equipment

- For determining the protection against high-velocity water jets.

- Box-type water jet test chamber & open-type water jet test device available.

- Fitted with 2 nozzles of 6.3 mm diameter for IPX5/6K, and 12.5 mm diameter for IPX6.

- The turntable is rotatable at a set speed.

- The nozzle can swing up and down automatically as needed.

- PLC and touch screen as control unit to enable easier control and automatic operation.

IPX7/IPX8 Water Immersion Test Equipment

- Suitable for IPX7 temporary and IPX8 continuous immersion testing in water under a specified pressure.

- IPX7 test equipment is provided with an electric hoist to allow the sample to move up and down in the water under control.

- Part of the shell of the IPX7 tank is made of thickened tempered glass, facilitating you to observe the specimen’s position, height, and state during testing.

- IPX8 tank features a sealed container with a pressurization function, which can simulate a pressure environment with a maximum water depth of 50 meters.

IPX9/IPX9K Water Spray Test Chamber

- Used for determining the protection against high pressure and temperature water jets.

- Fitted with 4 fan jet nozzles inside the chamber to spray the sample at 0°, 30°, 60°, and 90°.

- The water flow rate of 14 ~ 16 L/min under the pressure of 8000 ~ 10000 kPa is provided.

- The water can be heated and remain at (80 ± 5) degrees centigrade.

- The turntable is rotatable.

- Fitted with a PLC and 7” touch screen for parameter settings, intelligent control, and real-time data presentation.

- The chamber specification can be tailored to different specimens.

What Is Ingress Protection Code and What Is Its Structure?

Ingress Protection Code is abbreviated as IP Code. It is a coding system composed of letters and numbers to express the extent of protection offered by an enclosure against access to hazardous parts, ingress of solid foreign objects, ingress of water, and to give additional information in connection with such protection.

The structure of the IP code as below:

| Elements | IP | First characteristic numeral | Second characteristic numeral | Additional letter (optional) | Supplementary letter (optional) |

| Explanation | Code letters (international protection or ingress protection ) | Numerals from 0 to 6K or letter X | Numerals from 0 to 9K or letter X | Letters A, B, C, D | Letters M, S |

What Is Ingress Protection IP65?

Code “IP65” contains 2 characteristic numerals of “6” and “5”.

“6” means the degree of protection as below:

Protect the equipment inside the enclosure against ingress of dust

Protect persons against access to hazardous parts with a wire having a diameter of 1.0 mm and greater

“5” means the degree of protection as below:

Protect the equipment inside the enclosure against water jets from any direction.

What Is the IPX Waterproof Rating Chart?

The IPX Waterproof rating chart summarizes the waterproof protection ability of the casing to its internal equipment under different waterproof grades from IPX1 to IPX9K. The larger the value, the more severe the requirements for the waterproof level. Specific IPX rating descriptions are described in the table below. You can choose the corresponding test items according to the waterproof requirements you want to achieve.

The IPX rating table are as below:

| IPX Code | Degree of Protection |

| IPX0 | None |

| IPX1 | Protect the equipment inside the enclosure against vertical water drips |

| IPX2 | Protect the equipment against vertical water drips with the enclosure inclined by 15° in four directions, respectively |

| IPX3 | Protect the equipment inside the enclosure against spraying water |

| IPX4 | Protect the equipment inside the enclosure against splashing water |

| IPX4K | Protect the equipment inside the enclosure against splashing water with increased pressure |

| IPX5 | Protect the equipment inside the enclosure against water jets |

| IPX6 | Protect the equipment inside the enclosure against strong water jets |

| IPX6K | Protect the equipment inside the enclosure against strong water jets with increased pressure |

| IPX7 | Protect the equipment inside the enclosure against the effects of temporary immersion in water |

| IPX8 | Protect the equipment inside the enclosure against the effects of continuous immersion in water under conditions agreed upon by the interested parties |

| IPX9/IPX9K | Protect the equipment inside the enclosure against high pressure and high temperature water jets |

What’s IP67 Test Procedure?

According to the requirements of the relevant standards for the protection level of the equipment, the products that pass the ip67 test can be completely dust-proof and withstand water penetration after being temporarily immersed. That is, the product’s enclosure can prevent dust from entering the inside of the device. After putting the product into the water at a specified depth for half an hour under a normal temperature environment, it will not cause harmful effects on the product or impair its performance.

The IP67 test is performed in 2 sections.

Section 1: Test the IP6X dust resistance

Put the sample into a dust chamber with talcum powder of specified mass, then start the machine to keep the talcum powder in suspension in the chamber, fully exposing the sample to the dust environment, and continue the test for a specified duration (depending on sample properties as per standard requirements). After the test is completed, disassemble the sample shell for inspection. If there is no dust intrusion inside the shell, it is considered to pass the test.

Section 2: Test the IPX7 Water resistance

Immerse the sample into the immersion tank for 30 minutes at a specified depth per standard. After the test time is up, remove the sample from the tank. Check whether the sample is still functioning properly. If there is no negative impact on the normal operation of the equipment and it weakens its performance, the test is deemed to be passed.

More FAQs

Request a Quote Now