Push Pull Tester Machine China Manufacturer & Supplier

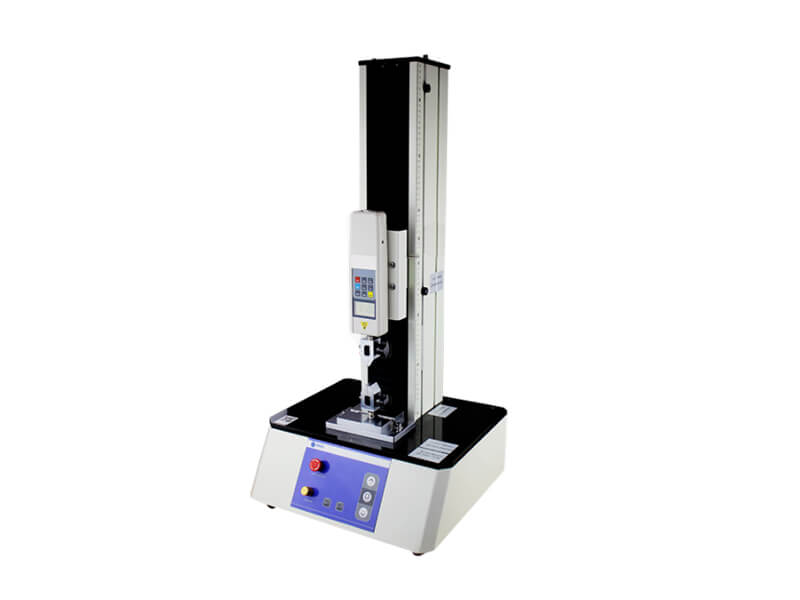

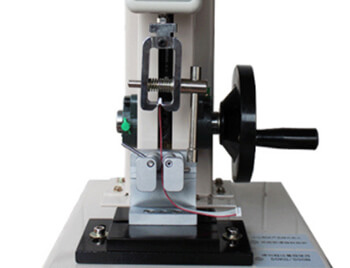

This manual push pull tester is designed to measure tensile and compression forces up to 1000 N (100 kgf). Unlike the horizontal pull test machine, which occupies a larger space, this instrument has a vertical structure. It allows specimens to be stretched perpendicularly during the test. The height of the pull tester reaches 500 mm. It is a compact tensile pull test machine, and its weight is 15 kg, so you can easily place it on the workbench for testing.

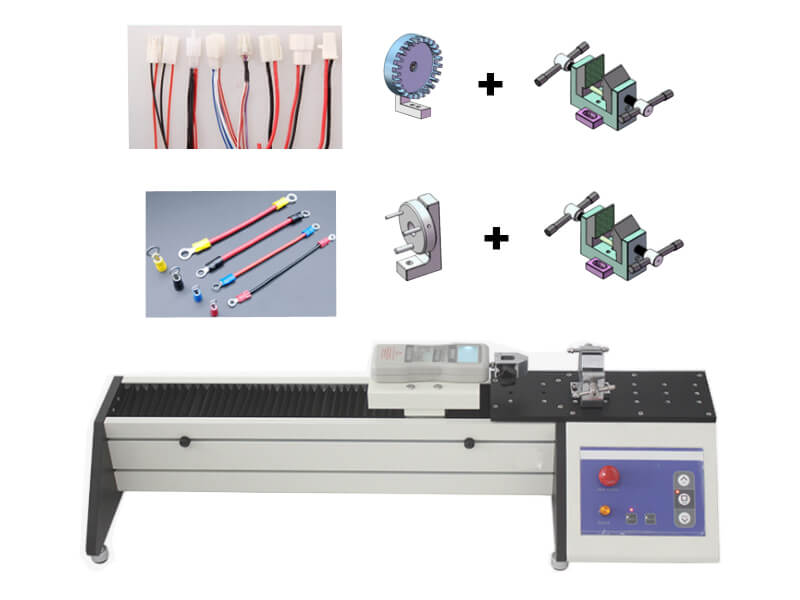

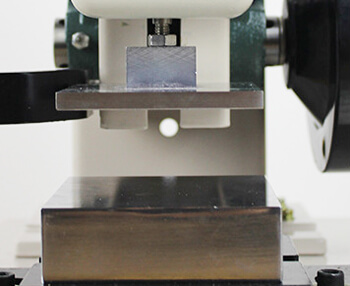

This pull test machine is a versatile instrument, especially used as the wire crimp pull tester. It can perform various tests by configuring different fixtures such as tension, compression, bending, peeling, shearing, tearing, puncture, etc.

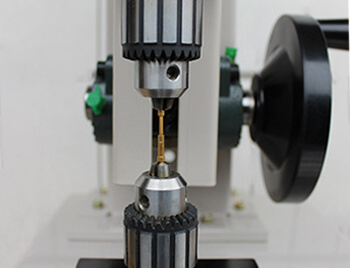

The mechanical part of the manual pull tester adopts a fully enclosed structure. The mechanical transmission system adopts high-precision ball screws and linear guides, with a tiny rotation gap and high transmission efficiency, which greatly improves the accuracy of the test. It is equipped with a handwheel in the middle of the stand. You can turn the handwheel to move the digital push-pull gauge up and down to realize the tensile or compression test on the test piece. The design of the handwheel operating part uses the principle of leverage, enabling you to operate more conveniently and labor-saving.

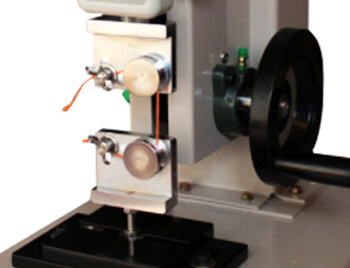

The stand of AT-U2-70 can be additionally equipped with a digital displacement scale with an accuracy of 0.01 mm, which can realize the simultaneous measurement of force and displacement and display the changes of force and displacement under each tension or compression in real-time. Please refer to the right picture of AT-U2-70B.

| Model | AT-U2-70 | |||||||||||

| Capacity | 2 N | 3 N | 5 N | 10 N | 20 N | 30 N | 50 N | 100 N | 200 N | 300 N | 500 N | 1000 N |

| 0.2 kgf | 0.3 kgf | 0.51 kgf | 1.02 kgf | 2.04 kgf | 3.06 kgf | 5.1 kgf | 10.2 kgf | 20.4 kgf | 30.6 kgf | 51.0 kgf | 102.0 kgf | |

| 0.45 lbf | 0.67 lbf | 1.12 lbf | 2.25 lbf | 4.5 lbf | 6.74 lbf | 11.24 lbf | 22.5 lbf | 45.0 lbf | 67.4 lbf | 112.4 lbf | 224.8 lbf | |

| Resolution | 0.0001N | 0.001 N | 0.01 N | 0.1 N | 1 N | |||||||

| Accuracy | ±0.5 % | |||||||||||

| Stroke | 150 mm | |||||||||||

| Units | N / lbf / gf | Kgf / N / lbf | ||||||||||

| Fixtures | A pair of fixtures corresponding to your sample (Tailored fixtures are optional) | |||||||||||

| Dimension | 360 mm ×260 mm × 500 mm (L × W × H) | |||||||||||

| Weight | About 16 kg | |||||||||||

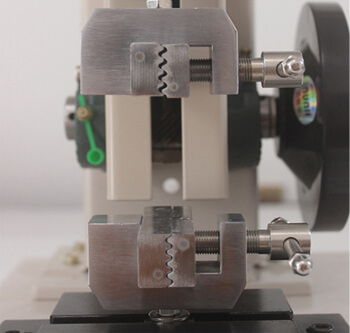

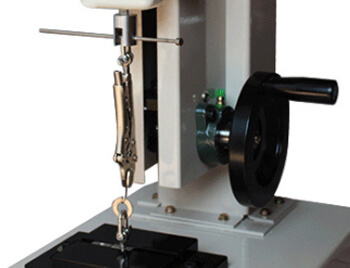

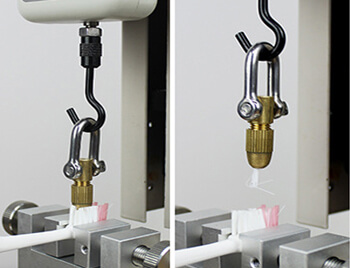

The matching fixtures and grips include but are not limited to the items listed below. If you want to learn more about the scope of testing or customize personalized fixtures, please feel free to contact us.

| Items | Reference Pictures |

|---|---|

| Sheet Specimen Grip |  |

| Fishhook pull test fixture |  |

| FPC pull test fixture & grip |  |

| Insertion force test fixture |  |

| Line pull test fixture |  |

| Can Ring-pull Test Fixture |  |

| Sponge compression test fixture |  |

| Toothbrush bristle pull test fixture |  |

| Wire terminal pull test grip |  |

Please click HERE to learn more about Grips & Fixtures for selection or contact us for fixtures customized.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.