AMADE TECH drop testers are used to simulate product or package drops from a specified height. Different parts of the product or package are repeatedly dropped to determine whether the product’s design is reasonable and whether the packaging can protect the product from damage during handling and transportation.

Drop test machines are usually used by R&D personnel to verify product design or develop product packaging in the early stage. The quality management department also uses them for routine inspections. The drop test on the packaging & product is the test item that covers many industries, such as lighting packaging, cosmetic packaging, electronic products, etc. Because these products are fragile or sensitive to drop during handling or distribution, it requires drop test equipment to verify whether the products or packaging have good resistance to drop.

The different styles of drop test machines for product and package drop tests are available from AMADE TECH.

The design of our drop tester machines is divided into several styles according to the product and package sample’s size and weight. Some drop testers are specially used for small and light consumer electronics such as mobile phones, tablets, and other digital products or handheld mobile devices. And some other drop test machines can be used for the drop test on the complete package loaded with the product, even on the heavy-duty and bulky packaging cartons.

Our drop test machines are designed to meet ISO, IEC, ISTA, ASTM test standards. Almost all of these different drop testers can be used to perform drop tests on the designated surface, corner, and edge of the sample.

The drop test is an essential item in testing many products and packaging materials, and it is a crucial indicator in evaluating the quality and durability of products and packaging. Conducting various drop tests is the most effective way to inspect product quality, ensure the safety of transportation of goods and packaging, and reduce economic losses. The drop testers have a wide range of uses in the industrial production and cargo transportation industries.

What Is the Drop Test Machine?

Laboratory Drop Test Machine is used to test the anti-drop strength of the product and verify whether the packaging and its cushioning materials can protect the product from the free-fall impact. The drop tester is an indispensable device for product research and development, packaging material design, carton selection, and quality management.

What Types of Drop Testers Does AMADE TECH Manufacture and Supply?

We are not only provide drop test machines for packages but also electronic products, including:

What Drop Test Standards Do Our Package Drop Test Machines Meet?

Our drop test machines follow drop test standards of packaging materials or cartons filled with products and standards of electronic products or electrical accessories.

- Series 1: ISTA 1A, ISTA 1B, ISTA 1C, ISTA 1D, ISTA 1G, ISTA 1H

- Series 2: ISTA 2A, ISTA 2B, ISTA 2C

- Series 3: ISTA 3A, ISTA 3B, ISTA 3E, ISTA 3F, ISTA 3H, ISTA 3K

- Series 6: SAMSCLUB, AMAZON.COM-SIOC, AMAZON.COM-Over Boxing, FEDEX-A. FEDEX-B

What Is the Difference Between Various Drop Testing Machines?

We have various drop testers for customers to select from. The following are the differences between these drop tester machines.

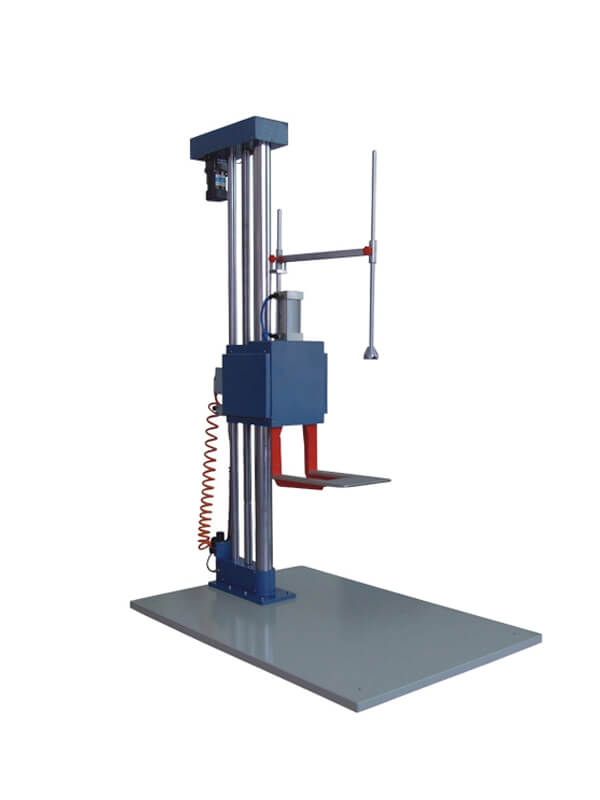

- Pneumatic Package Drop Tester

This is a precision drop tester people often use, which is mainly used for the drop test on packing boxes filled with stuff. The sample release during the test is by means of a pneumatic mechanism with a speed of more than 3G. In this way, the interference of the supporting plate to the sample drop can be reduced as much as possible to ensure the accuracy of the drop test results.

It usually can accept packages less than 68 kg. Its design complies with standards of ASTM, ISTA, ISO, IEC, JIS, EN, UPS, FedEx, Amazon, etc. It is an international mainstream drop test machine.

- Zero Distance Drop Tester

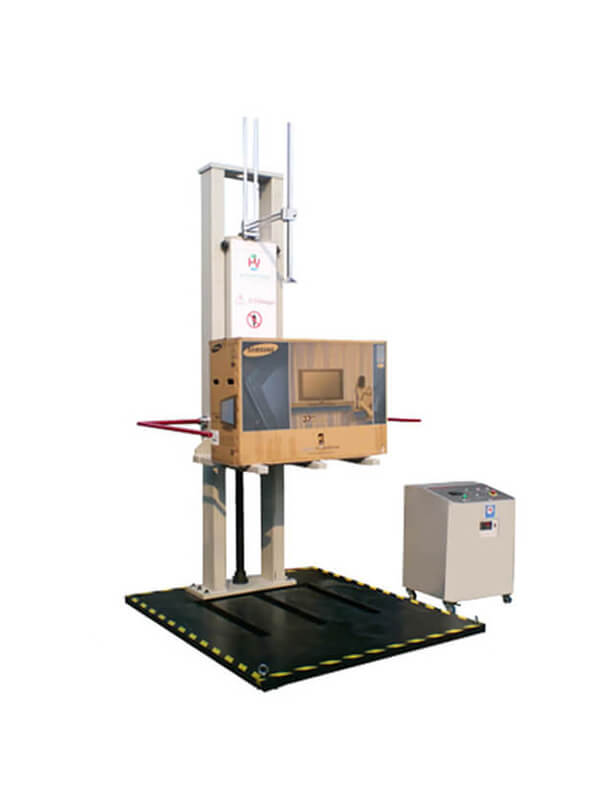

The zero distance drop test machine is mainly used for the drop test on larger or heavier packages. Generally, the weight of the package is heavier, the possible height of the vertical drop during transportation and handling is lower. Therefore, the drop height is required to be as low as zero theoretically.

There is an “E”-shaped fork as a bracket to hold the test piece before the drop, which can move down faster than the sample with the help of the pneumatic mechanism. The fork will impact and be embedded into the e-groove of the floor before the sample falls to the floor. Theoretically, the drop test can be performed from zero height up to the highest height of the machine.

The allowable maximum specimen mass is 100 kg, 200 kg, 300 kg, or more. Please feel free to advise us of the specimen mass you will test. We will select an appropriate model for you.

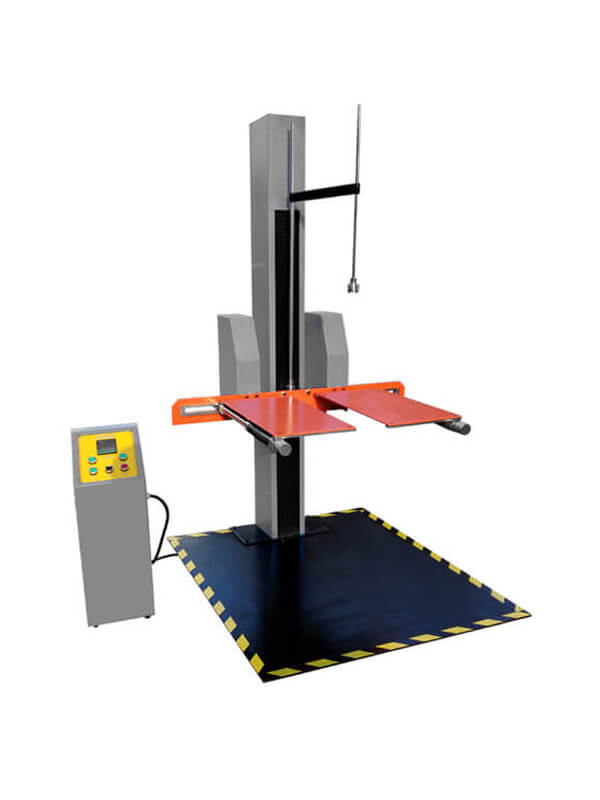

- Economical Drop Test Machine (Single Arm Drop Test Machine)

This is another drop test machine developed by us. It is mainly applicable to various packages. The single-arm drop tester is very suitable for daily packaging drop tests in the factory. It allows a single arm to support and release the specimen. It can also achieve drop tests on corners, edges, faces of packaging cartons. The minimum drop height is 300 mm, and the maximum load-bearing capacity of a single arm is up to 80 kg. Its price is lower than that of the pneumatic drop test machine.

- Double Arm Drop Tester

It is mainly applicable to packaging cartons. The load-bearing capacity of the regular double-wing drop test machine is 60 kg, and the lowest drop height is 400 mm. The supporting bracket of the test piece is composed of two separate pallets. The spacing of 2 pallets can be adjusted so that larger packages can be placed. The double-arm drop tester can conduct the test on the specimen’s surfaces, edges, and corners with the aid of a vertical rod. It is generally used for the irregular package drop test.

- Orientation Drop Tester

The orientation drop tester is mainly applicable to 3C products. The most prominent characteristic of the orientation drop testing machine is that it can more accurately locate the impact position of the sample while contacting the base plate than any other drop tester. It is due to the use of the guide rod and a unique sample holding and release mechanism. You can choose from two fixtures: a pneumatic clamping apparatus and pneumatic suction cups to achieve 0, 45, and 90-degree drop tests on the sample.

When pressing the test key, the fixture can drive the sample to drop quickly with average acceleration and release the sample quickly when approaching the floor. At the moment of impact, the sample posture is consistent with that set before the drop. Of course, it can also do the free-fall drop test. The maximum test height is 1800 mm, and the maximum acceptable sample mass is 2 kg. We can customize it for you if you want other higher heights or greater mass.

- Rotating Drum Drop Tester / Tumbling Barrel Testing Machine

The rotating drum drop tester is entirely different from other drop test equipment. It has at least one rectangular barrel that can be flipped over, and its drop height is 500 mm or 1000 mm. Before the test, a sample is placed into a barrel from a transparent window.

During the test, the specimen will be continuously overturned and dropped with the movement of the barrel. You can adjust the rotation speed of the barrel through the control panel at will ranging from 5 to 20 rotations per minute. The number of rotations is also displayed on a screen. When the specified number of turns is reached, the operator checks the sample for damage.

In addition to a single barrel, we are available to supply double barrels or custom multiple barrels. We can also install a transparent acrylic protective cover around the machine to protect the operator. The maximum acceptable sample mass of the tumbling barrel testing machine is 5 kg.

- Free fall Drop Tester

The free fall drop tester is mainly applicable to electronic products and small accessories. It allows the sample to drop in free fall from a specified height to the base plate. Depending on your test needs, you can choose different heights of testers, including 1.5 meters, 2 meters, 3 meters, or customized other heights. After the sample is pneumatically clamped and electrically raised to the specified height, different surfaces, angles and edges can be positioned to drop vertically to the ground. Generally, the maximum acceptable sample mass of the free fall tester is 3 kg or 5 kg.

- Battery Drop Tester

As you can tell from the name, The battery drop tester is specially designed for battery drop test. The machine adopts a fully enclosed structure to ensure the safety of the test. The allowable drop height ranges from 300 mm to 1500 mm, and the operator can freely adjust it. The built-in pneumatic gripper allows the specimen to fall from different angles. Equipped with a touch screen, the whole test process can be controlled by PLC.

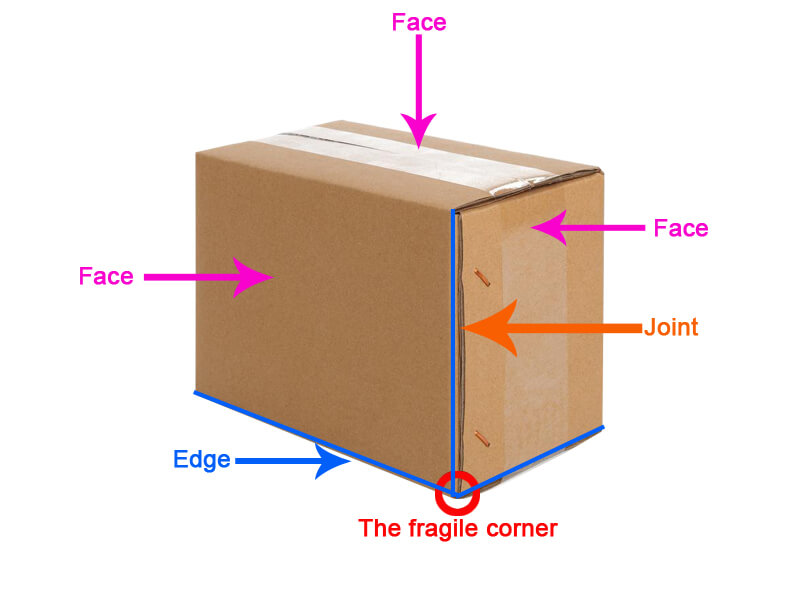

How to Mark the Faces, Edges, and Corners and Find the Weakest Part of a Carton?

Usually, the joints of the carton are the most vulnerable parts. The joints of the carton are stitched together with staples, glue, or tape, so this part of the carton is most needed to do the drop test.

You also can first locate one most fragile corner to complete a drop test, then perform three tests on three edges coming from that corner, at last, carry out six tests on six surfaces of the carton.

Please see the reference figure of the tested carton as follows:

How to Use a Drop Tester to Perform the Drop Test on the Product or Package?

Why Do You Choose Drop Testing Machines from AMADE TECH?

The drop testing machines that AMADE TECH supplies are intelligent and precision. It can precisely control the height and posture of the drop. It only needs one operator to easily complete the drop test of hundreds or even thousands of samples. It is easy to operate, saves labor costs, and improves test efficiency.

AMADE TECH can supply different types of drop testers to accommodate a wide variety of packages and products. Our drop testers loads contain 3 kg, 5 kg, 80 kg, 200 kg, even 500 kg or more. The drop test of the packaging carton is a necessary inspection item before the product is shipped. You can imagine if your end customer receives the package and open it, and finds that they are damaged products. What a terrible shopping experience it will be, or the function of the product received by your dealer has been damaged and cannot be sold, and you will have to pay compensation. Here our drop testers can help you save worries.

AMADE TECH provides high-quality drop testers at attractive prices. To deliver reliable products to customers, we comply with international standards, from product design to manufacturing. The raw materials are high-quality steel, and the core components are of internationally renowned brands. Each product will be calibrated and tested before leaving the factory. We provide a guarantee period of at least one year. If there is any problem, we will help solve it for free. The price we give to our customers is also very competitive, cheaper than that from the local market. If you have any questions, please feel free to contact us to learn more.