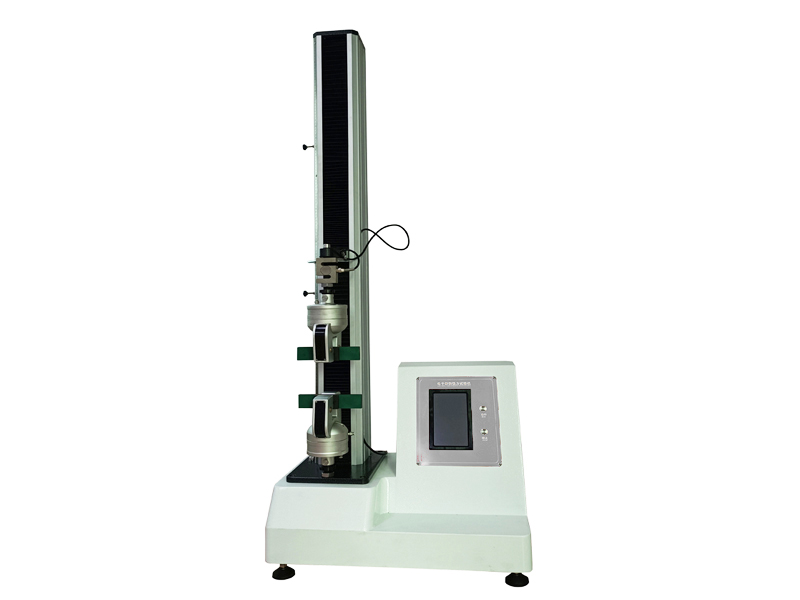

AT-T4006 Button Snap Pull Tester China Manufacturer

Button Pull Test Machine is also referred to as the button snap pull tester. It is mainly used as a textile testing machine or a toy testing machine intended to determine the breaking or pull strength of buttons, snaps, fasteners, ornaments, etc,. attached to garments, fabrics, toys, shoes, etc.

This snap button pull test machine is an effective tool to help manufacturers to check whether various attachments of the final products are firmly fastened and reach the specified requirements. If the buttons on the baby clothes are easy to fall off, which is not only a quality problem but also a hazard of being swallowed by the baby in contact. Therefore, all buttons and decorative parts on garments must be tested with a button snap pull tester in the product development stage and during the spot check on finished products to check whether their firmness meets relevant safety standards.

There are 2 measuring methods: One is that the operator operates the instrument to continuously apply a pulling force to the targeted button, attachment or ornament until it is separated from the base sheet of the specimen. The force required at the time when the stripping occurs is recorded as the test result.

The other is that a constant pulling force is applied to the button or ornament for a specified period of time. The operator inspects whether the attachment and the base sheet are separated or the damage to the specimen occurs. The state of the measured sample is recorded as the test result.

We can supply different styles of pull testers. In addition to analog machines, we can also supply digital display models and electromechanical models. For more styles and grips, please contact us directly.

Analog Button Snap Pull Tester

- AT-T4006-A1

- Equipped with a analog push & pull gauge

- Wheel-operated + Lever-operated

Digital Button Snap Pull Tester

- AT-T4006-B2

- Equipped with a digital push & pull gauge

- Wheel-operated

Manual Pull & Compression Tester

- AT-T4006-C2

- Equipped with a digital push & pull gauge

- For pull & compression testing

| Model | AT-T4006 |

| Moving Stroke | 300 mm |

| Force Gauge | 30 kgf / 300 N |

| Dimension | 280 × 220 × 820 mm (L × W × H) |

| Weight | 35 kg |

| Optional Force Gauge | IMADA FB-30K |

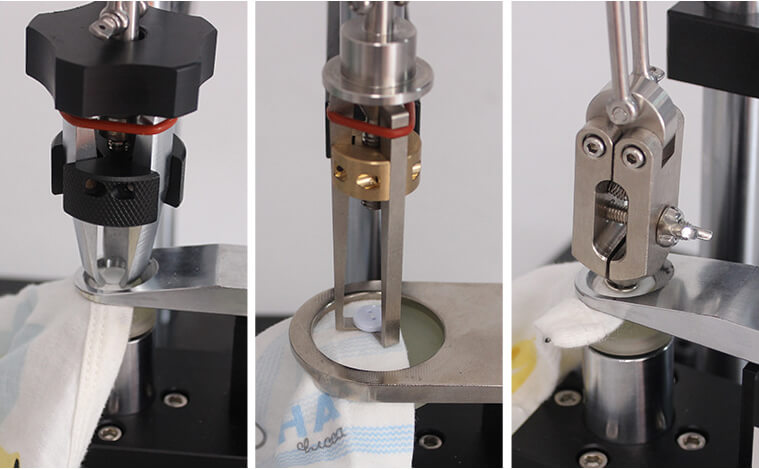

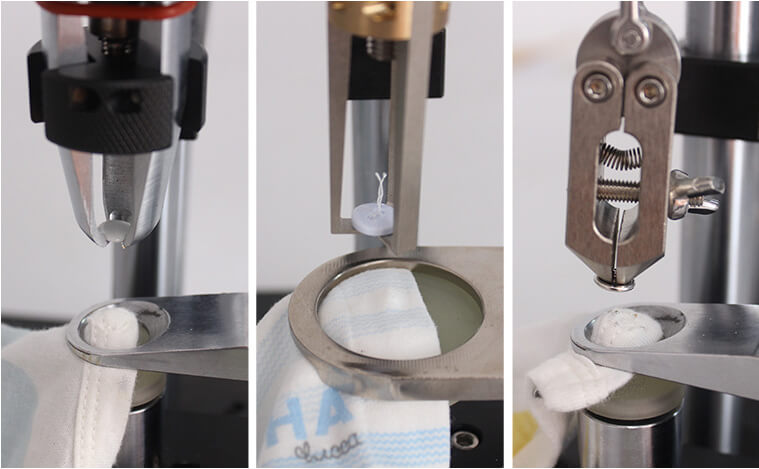

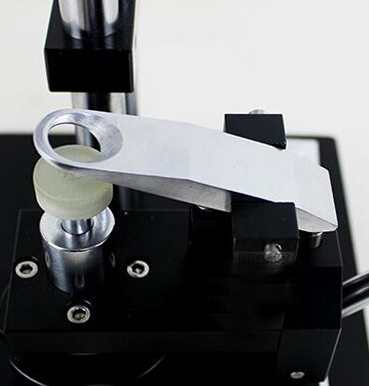

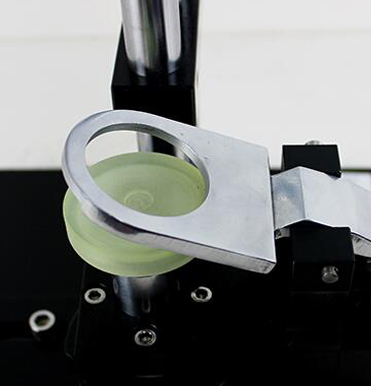

A piece of fabric with a button or other ornament is placed on a circular rubber pad and clamped by a ring-shaped fixture, enabling the targeted attachment to be up and in the middle of the ring. A matched upper gripper connected to the force gauge is adjusted downward by turning the handwheel to grip the attachment.

An upward force is applied by turning the handwheel to pull the attachment for a given period of time or until the failure of the specimen occurs. The holding or breaking strength is measured.

- 16 CFR 1500.51-53

- 1500.51 – Test methods for simulating use and abuse of toys and other articles intended for use by children 18 months of age or less

- 1500.52 – Test methods for simulating use and abuse of toys and other articles intended for use by children over 18 but not over 36 months of age

- 1500.53 Test methods for simulating use and abuse of toys and other articles intended for use by children over 36 but not over 96 months of age

- ASTM D7142-5 Standard Test Method for Holding Strength of prong-ring Attached Snap Fasteners

- EN71-1

- ASTM D4846 Standard Test Method for Resistance to Unsnapping of Snap Fasteners

- ASTM F963 – Standard Consumer Safety Specification for Toy Safety

- M&S P115A

- ASTM PS79-96

What Grips and Accessories Can I Get with the Snap Button Pull Test Machine Together?

We will provide a set of standard accessories with the machine to meet the testing requirements of most customers. If your test sample is very special and requires unconventional grips to complete the test, you can buy it separately from us.

The standard accessories are as follows:

1. A force gauge

This force measuring device is the core component of this button snap pull tester, because it is responsible for measuring and displaying the pulling force of the sample during the test. It is an analog gauge with a pointer and scale or Push-pull meter (Force gauge) with an LCD screen, featuring high accuracy, easy operation and intuitive reading. Its maximum scale is 300N. (If you want to choose a high-end force gauge, IMAD is an alternative).

2. A Calibration Weight(15 lb)

It is used to calibrate the accuracy of the force gauge (15 lb = 6.82 kg)

3. Lower Fabric Clamping Device & Level Arm Locking

A sheet of fabric test piece with a button is flat placed on the rubber pad and clamped by the locking mechanism to prevent slippage during the test.

4. Lower Grasp Button Accessory Kit

This set of kit is mounted to test on grasp buttons or large buttons up to 30 ligne. It is mainly used together with the upper grasp button grip.

long nose vise grip

three-pronged grip

upper grasp button grip

upper universal female grip

upper stud clamp

5. A long Nose Vise Grip

It looks like a long nose and features a vise with 2 jaws to clamp hooks for trousers, retaining rings and other small accessories on garments.

6. A Three-Pronged Grip

It features 3 prongs on the gadget. The clamping mouth is adjustable to accommodate attachments of different sizes.

7. An Upper Grasp Button Grip

It is designed to grip the grasp buttons or larger buttons, like Jeans or plastic buttons up to 30 ligne. A special lower clamping kit is provided by us to match this grip.

8. An Upper Universal Female Grip

It is intended to test on the female part and stud part of the snap, which is one of the most commonly used grips.

9. An Upper Stud Clamp

It is used to test on the male part of the snap, but generally, upper universal female grip can be also used instead.

The optional accessories are as follows:

1. Small Part Cylinder

This cylinder is used to confirm whether the accessories are classified as small parts or not in conformity with EN71 & ASTM F963.

2. Multi-Function Vise Clamp

It is used to fasten the fabric between the jaws and can be used with other upper grips for testing on the attachments like Patches, side tabs, zippers, pullers, etc.

3. Flat Grip

It looks like a scissor and is intended to grip various small attachments like jeans buttons.

4. Two-Pronged Grip

It features 2 prongs, and the clamping mouth is adjustable to grip various sizes of attachments.

5. Seam Fixture

It is used as the close clamp and round cake tong, and features test tension with seam.

6. Straight Teeth Clamp

7. Zipper Test Kit

small part cylinder

multi-function vise clamp

two-pronged grip

button flat grip

fabric seam grip

FAQs

Send an Inquiry

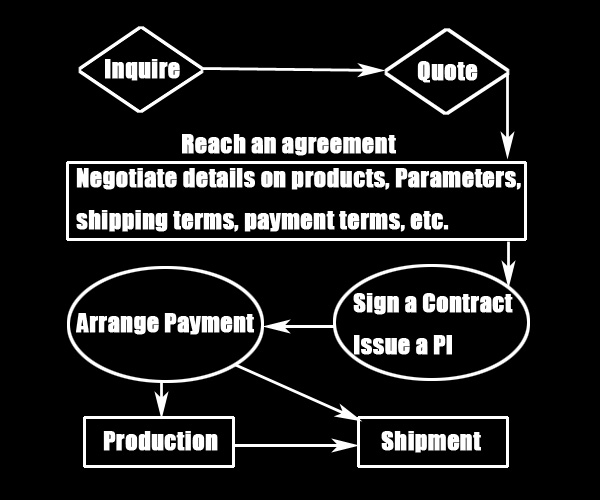

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.