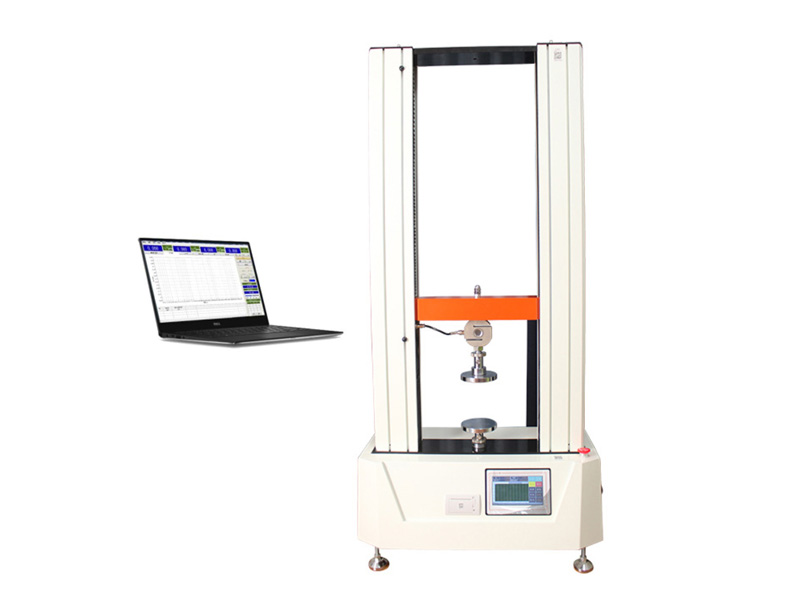

Computerized Tensile Strength Machine China Manufacturer

Electromechanical Universal Testing Machine is a hot-selling mechanical testing machine intended to carry out the tensile, compression, flexural, shear, etc., tests on a wide range of test pieces, including cloth, rubber, plastic, textiles, paper, leather, etc.

The double-column construction and the fixed crossbeam at the top form a solid frame. The force output by the precision motor acts on the moving crossbeam through the screw drive under precise control to realize its up and down movement.

This UTM features a computer as the control terminal. Thanks to the powerful hardware and versatile control software, It integrates measurement, control, calculation, storage functions into one device. Without the computer, this electromechanical universal testing machine can also complete a variety of tests. Real-time data and curves are displayed on the built-in touch high-definition screen.

Judging from the literal meaning of “Universal”, this electromechanical universal testing machine is an all-purpose device. The user only needs to replace the fixtures or grips on the device to determine the different mechanical properties of different materials. As a result, this instrument has an extensive range of applications, covering the tension test, compression test, bending test, shear test, peel test, tear test, etc. It is a piece of the necessary equipment in aerospace, electronics, plastics, packaging, automobiles, luggage, textiles, and other fields.

This universal testing machine has excellent performance on the automatic measurement and calculation of stress, elongation, tensile strength, elastic modulus, etc. It can automatically record the maximum point, breaking point, specified point of force value, or elongation. The computer is used to set parameters and display the dynamic changes in a curve manner during the testing process and carry out the data analysis and output.

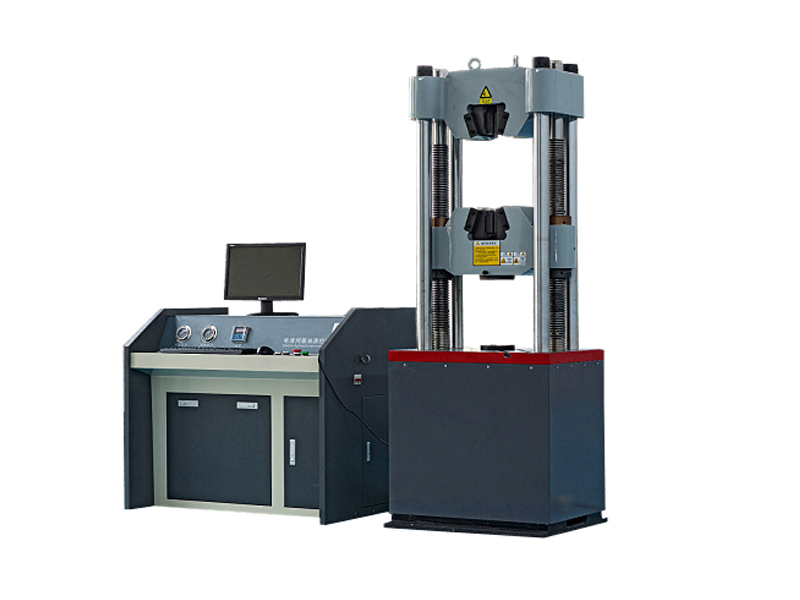

Test Principle

For the tensile test, both ends of the specimen are clamped in the two grips (the lower one is fixed, the upper one connected to the crosshead is movable). The tensile force is exerted gradually when the upper clamp is moving upward. The computer gathers values of the force and displacement in real-time by means of the load cell secured in the grip assemble and optical-electricity encoder in the machine. The test results can be calculated and analyzed automatically by professional testing software. The real-time data and curves involved in the load, elongation, time, etc. will be displayed.

For the compression test, the specimen attached to the lower fixture bears a compressive strength downward from the upper platen. The rest procedure is controlled and processed by a computer, the same as that of the tensile test.

Main Technical Parameters

| Model | AT-U2002 |

| Capacity | 500 N, 1000 N, 2500 N, 5000 N, 10000 N (Optional) |

| Unit | N, kN, kgf, gf, Ton, lbf |

| Load Accuracy | ± 0.5% |

| Force Resolution | 1/250,000 |

| Deformation Resolution | 0.001 mm |

| Test Speed | 0.5 mm / min ~ 500 mm / min |

| Test Travel | 500 mm (exclude fixtures) or customized |

| Spacing Between Two Columns | 400 mm |

| Communication Interface | Ethernet |

| Control Mode/Display/Output | Computer, Professional testing software |

| Stop Method | By upper and low target force / displacement or limit set, emergency stop, the specimen breaking sensing, etc. |

| Drive Mode | AC serve motor + Precision ball screws |

| Fixtures and Grips | Based on customer’s test sample |

| Dimension | 760 mm × 600 mm × 2100 mm (W × D × H) |

| Weight | Appr. 300 kg |

| Power Supply | AC 220 V,50 Hz,1 phase or AC 110 V, 60 Hz, 1 phase |

Electromechanical Universal Testing Machine Features

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AMADE TECH sales specialists will respond within one working day.