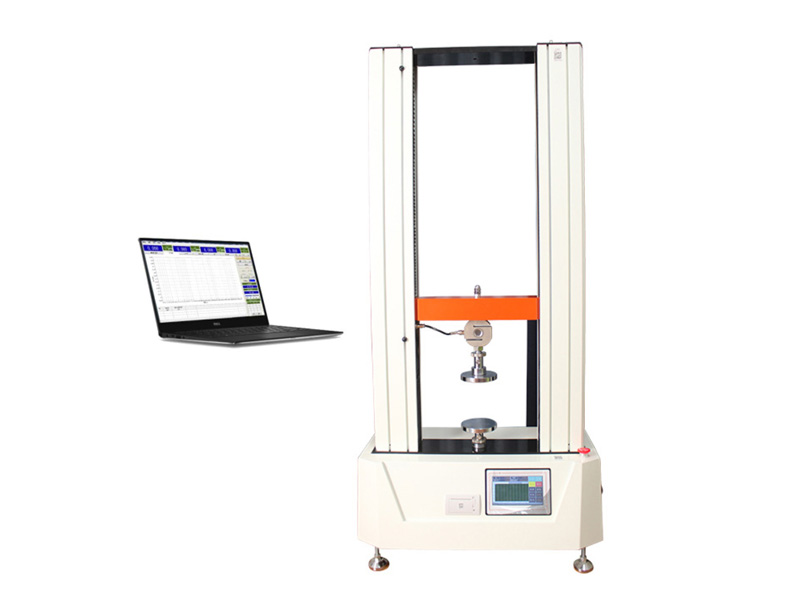

Tensile Strength Measuring Machine China Manufacturer

UTM (Universal Testing Machine) is a widely used tensile / compressive strength measuring machine. It belongs to the electromechanical universal testing machine, working on testing mechanical properties of specimens through stretching, compressing, bending, shearing, etc. The UTM is one of the indispensable testing instruments in material development, quality control, teaching research, etc.

If classified according to the control method, the universal testing machine is divided into electronic touch screen control and computer control. This machine AT-U2001 is a touch screen controlled electromechanical testing machine. It can display various parameters in real time and output different curves at the same time during the test.

Applications of the UTM

The universal testing machine are mainly used for the tensile test & compression test.

Essential Technical Parameters

| Model | AT-U2001 |

| Capacity | 500 N, 1000 N, 5000 N (optional) |

| Unit Exchange | N, kN, kgf, gf, Ton, lbf |

| Load Cell Accuracy | ± 1% |

| Force Resolution | 0.01 N |

| Deformation Measurement Resolution | 0.01 mm |

| Test Speed | 5 mm / min ~ 500 mm / min |

| Test Travel | 500 mm (exclude fixture) or customized |

| Control Mode/Display/Output | Microprocessor + LCD touch screen |

| Stop Method | By upper and low target force, target displacement, limit switch, emergency stop, specimen breaking sensing, etc. |

| Transmission Mode | Stepper motor |

| Fixtures and Grips | Fitted to customer’s test sample |

| Print Content | Test speed, max. load, max elongation, tensile strength, curve, etc. |

| Dimension | 600 mm × 500 mm × 1400 mm (W × D × H) |

| Weight | Appr. 85 kg |

| Power Supply | AC 220V,50 Hz,1 phase /AC 110 V, 60 Hz |

Tensile Strength Measuring Machine Features

Hot to Buy a Right Electromechanical Universal Testing Machine

If you don’t know how to choose an electromechanical universal testing machine, don’t worry. Please tell us your request directly. AMADE TECH’s sales engineers will help you configure a satisfactory machine.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AMADE TECH sales specialists will respond within one working day.