Peel Adhesion Strength Tester China Manufacturer & Supplier

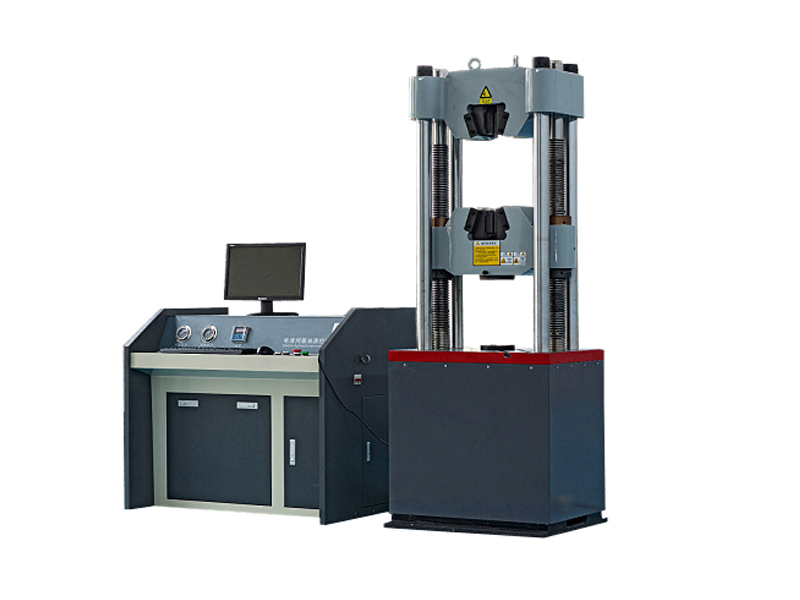

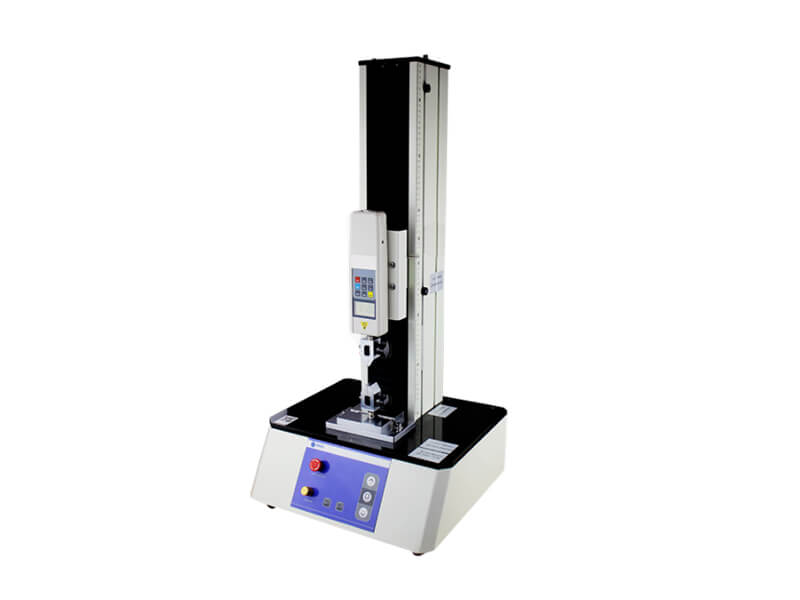

Peel Tester is a tensile testing machine compatible with various peel fixtures. It is featured with constant rate-of-extension and constant rate-of-load control. By matching different jigs and attachments, this peel force tester allows you to perform a wide variety of peel strength tests, including:

- The bond strength test of adhesives, glues, cement adhesives

- The interlayer peel strength test of laminated materials

- The tape peel test

- The peel-off test of lid films

- The peel adhesion test of fabric coatings

- The peel bond strength test of labels, medical stickers, protective films, and release paper

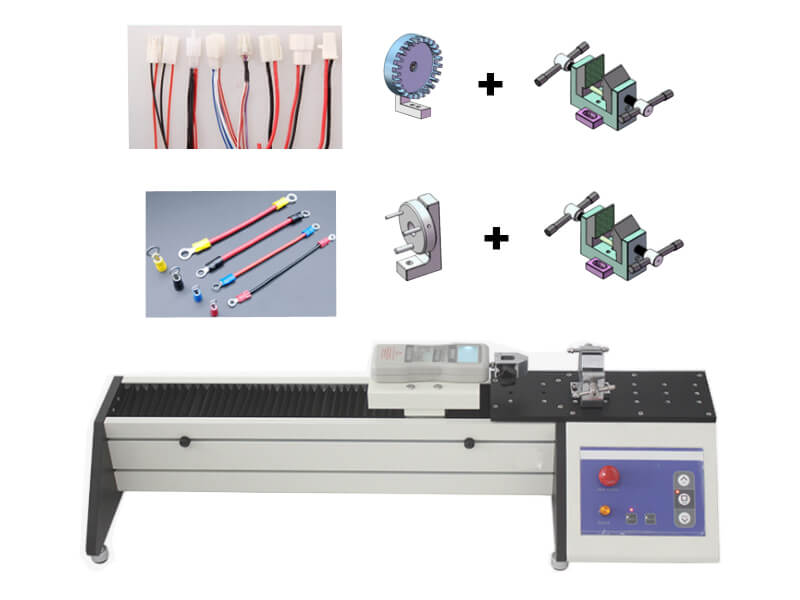

- The peel test of electronic components, carrier tapes

- The heat sealing strength test and peel force test of packaging films

- The unwinding force test of pressure-sensitive adhesive tapes at low speed

In addition, it is also commonly used for determining the tensile strength, elongation, breaking force, shearing, tearing strength, etc., which has the same functions of the electromechanical universal testing machine.

- The following fixtures and grips can be used on our peel bond strength tester to determine the peel strength, bond strength, and shear performance test of specimens:

- AT-U2P02

- 90 degree peel test fixture

- AT-U2P03

- 180 degree peel test fixture

- AT-U2P04

- Loop tack peel test fixture

- AT-U2P05

- floating roller peel fixture

- AT-U2P06

- Climbing drum peel test fixture

- AT-U2P07

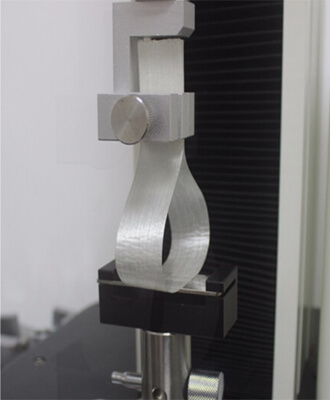

- T-type peel test gripping device

- AT-U2P08

- Rotating wheel peel test fixture

contact us to help you configure right fixtures for your applications

What Peel Tests Can Be Performed by Our Peel Testers?

45 degree peel test

90 degree peel test

180 degree peel test

Loop track peel test

Floating roller peel test

Climbing drum peel test

T-type peel test fixture

Plastic film heat sealing (bonding) strength test

Because the application of the peel tester is too rich, we can’t list them all here. If you are looking for a peel test machine with desired fixtures, please directly contact us for more details.

| Capacity | 10N, 20N, 50N, 100N, 200N, 500N, 1000N, 5000N, 10000N, 20000N(Optional) |

| Style | Single column / double column |

| Load Accuracy | 0.5 level |

| Measuring Accuracy | Greater than ± 1 % or Greater than ± 0.5 % (Optional) |

| Drive Mode | Inverter motor, stepper motor, servo motor (Optional) |

| Controller | Modularization + Touch screen control

Professional test software + Personal Computer (Optional) |

| Test Speed | 0.001 ~ 500 mm / min, or up to 1000 mm / min or higher (Customized) |

| Test Travel | 500mm, 1000mm or higher (Customized) |

| Test Data | Peel force, peel strength, maximum value, minimum value, average value, force-displacement graph. |

| Work voltage | AC 220V or 110 V 50 / 60 Hz, 1 phase |

180 Degree Peel Test Standards:

ASTM-D3330

ASTM-D5458

ASTM-D903

ASTM-F88

BS EN-1939

BS EN ISO-8510-2

Afera-5001

FINAT-FTM1

FINAT-FTM3

ISO-11607-1

ISO-8510-2

PSTC-101

PSTC-4

PSTC-8

SAE-J 1907

TLMI-L-IA1

TLMI-L-IA2

90 Degree Peel Test Standards:

Afera-5001

ASTM-B533

ASTM-B571-97

ASTM-D3330

ASTM-D429

ASTM-D6252

ASTM-D6862

ASTM-D816

BS EN-1939

BS EN-2243-3

BS EN-28510-1

FINAT-FTM2

IPC-TM-650

ISO-8510-1

SAE-J 1553

Climbing Drum Peel Test Standards:

ASTM-D1781

BS EN-2243-2

Floating Roller Peel Test Standards:

ASTM-D1995

ASTM-D3167

BS EN-1372

BS EN-1464

DIN EN-1464

ISO-10373-1

ISO-14676

ISO-4578

Loop Tack Peel Test Standards:

ASTM-D6195

BS EN-1719

FINAT-FTM 9

PSTC-16

T-Peel Test Standards:

ASTM-D1876

ASTM-D1995

ASTM-D2918

ASTM-D413

ASTM-D5170

ASTM-D6496

ASTM-F2256

ASTM-F88

BS EN-12242

BS EN-1895

BS EN-868-5

ISO-11339

ISO-20344

Comparison of the Peel Tester Machine’s Two Control Modes

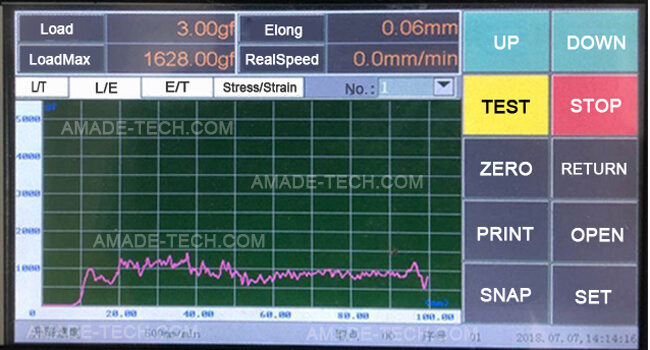

Modularization +Touch Screen

Operation Interface

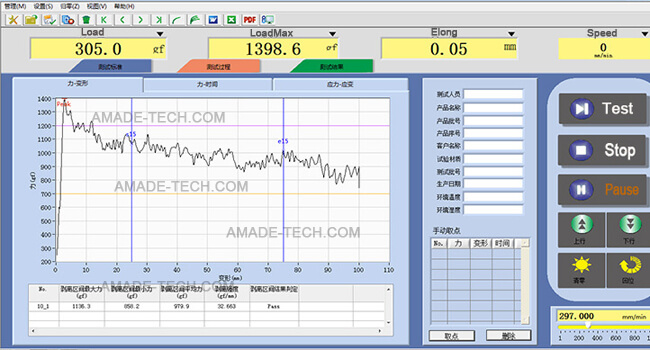

Windows-based Test software + PC

PC Software Interface

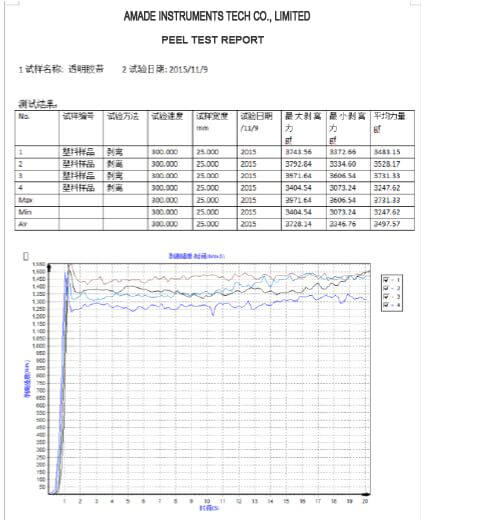

Test Report

Learn More About the Peel Test

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.