Lithium-ion Battery Forced Internal Short Circuit Testing Equipment China Manufacturer

Li-ion Cell Forced Internal Short-Circuit Tester is used to simulate the short-circuit between positive and negative active material coated area or between positive aluminum foil and negative active materials coated area of cylindrical cells or prismatic cells. The safety of the sample cells is determined by whether they catch fire during the test.

Our forced internal short-circuit tester features a temperature-controlled chamber and a set of press equipment in it.

The chamber enables you to set any desired test temperature from 0 to 100 degrees Celsius. The temperature in the chamber is uniform, and the heating and cooling speed are fast. The moving part of the press equipment with a maximum load of 1000 N can move at a constant speed and be stopped immediately when an internal short-circuit is detected. The position of the pressing jig is allowed to be maintained for a specified time before the pressure relief. The bottom surface of the pressing jig comes with a piece of nitrile rubber for the cylindrical cell test and a piece of acrylic resin attached to the nitrile rubber for the prismatic cell test.

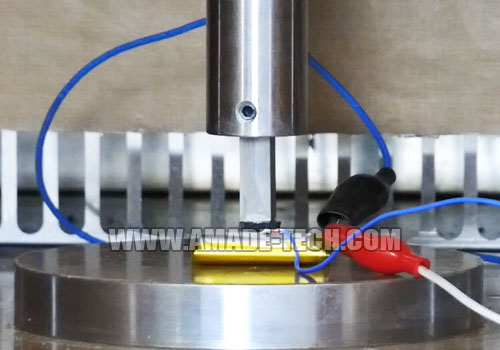

Test on the prismatic cell

Inside the short-circuit test chamber, we configure a pair of wire clips to connect to the positive and negative poles of the winding core for voltage measurement and thermocouple terminals to attach to the surface of the winding core for temperature measurement.

During the descent of the pressing jig, any of the three conditions of pressure, voltage, and deformation can be used as a single condition for ending the test.

You can also use any combination of these three test conditions as control variables. That is, after setting three or two test conditions at the same time, when any one of the conditions is satisfied, the machine will stop the test.

The entire test is controlled and run automatically by professional software installed on our configured computer. The software supports the input of various parameters, real-time data monitoring, and test results output.

Test on the cylindrical cell

If you are looking for a lithium-ion battery external short circuit tester, please go HERE.

| Model | AT-L5010 |

| Temperature-controlled Chamber | Temperature range: 0 ° C ~ 100 ° C

Accuracy: ± 0.1 °C Temperature fluctuation: ± 0.5 °C Temperature uniformity: ± 1.5 °C Heating rate: average 3 °C / min (from 0 ° C to 100 ° C, nonlinear no-load, average temperature rise) Cooling speed: average 1 °C / min (from 100 ° C to 0 ° C, nonlinear no-load, average temperature drop) Interior chamber dimension: 400 mm (W) × 500 mm (H) × 400 mm (D) Interior chamber material: 304 stainless steel plate, with reinforced ribs at the bottom |

| Press Equipment | Test load: 0 ~ 1000N adjustable (usually 400 N and 800 N needed)

Load accuracy ≤ 0.5% F.S Pressing speed range: 0.01~20mm/s adjustable (common test speed: 0.1 mm / s) |

| Voltage Acquisition | Range: 0 ~10 V

Resolution: 1 mV Acquisition frequency: 100 Hz |

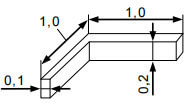

| Pressing Jigs | Standard pressure jig elements:

① Stainless steel shaft: 10 mm x 10 mm ② Nitrile rubber: 10 mm x 10 mm x 2 mm (T) – for cylindrical cells ③ Acrylic resin 10 mm x 10 mm x 2 mm (T) – for prismatic cells |

| Nickel Particle |  |

| Related Devices | For more battery safety testing equipment, please click HERE |

- IEC 62133-2

- JIS C 62133-2

- IEC 62660-3

- IEC 62619, etc.

Cell Forced Internal Short-Circuit Testing Machine Features

FAQ on Forced Internal Short-Circuit

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AMADE TECH sales specialists will respond within one working day.