Mechanical Shock Test System and Equipment China Supplier

Mechanical Shock Tester is used to simulate the shock wave and shock energy that components, finished products or packaging may suffer during use and transportation, to determine the shock resistance of products, such as functional reliability and structural integrity in shock environments, and to assess the protective ability of the packaging. It is widely used in aerospace, shipbuilding, military, automotive, consumer electronics and other industries.

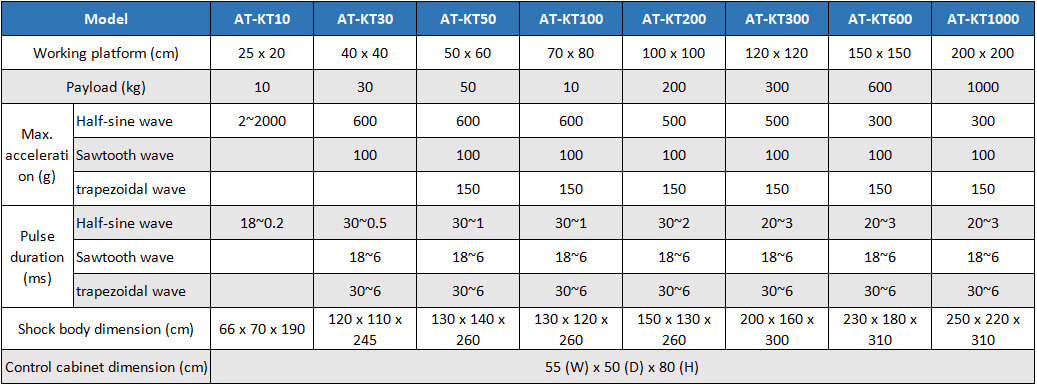

Our shock test machines are capable of performing shock tests of half-sine, sawtooth, trapezoidal and other waveforms. The specimen is mounted to the working platform and can be elevated to a specified height under the guidance of vertical precision guide bars. The desired peak acceleration and pulse duration are achieved with the cooperation of the waveform generator at the bottom of the base after the shock occurs. Waveform generators of different specifications can be easily replaced by manual.

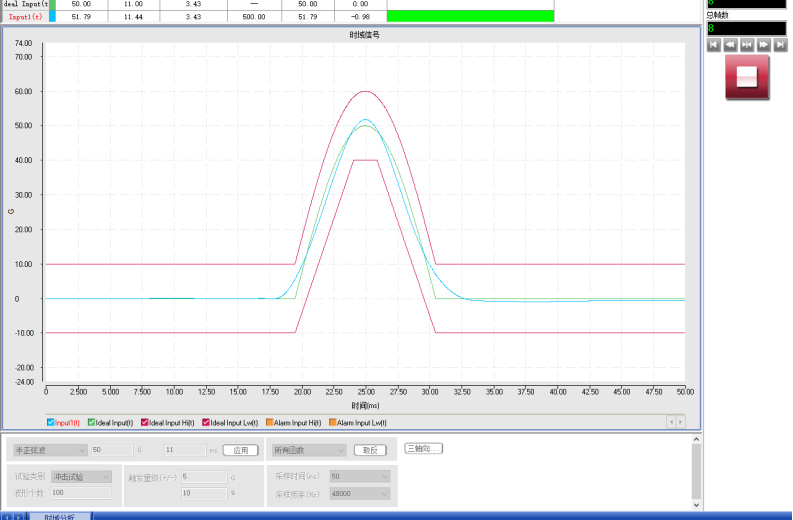

The mechanical shock test equipment is installed with professional shock testing software in English. All parameter settings and test controls are realized through a built-in computer and a touch screen on the face of the control cabin. The operation is simple and convenient and supports manual lifting and lowering of the shock head assembly. After the setting is completed and the test is started, the mechanical shock tester can automatically complete multiple impacts. All real-time parameters and waveforms are displayed on the computer screen. The measurement system has a robust sampling rate of up to 1 MHz, which has the ability to capture the shock waveform accurately and quickly. All test data can be stored, recalled, printed, etc.

Let’s take the shock test in Chapter 38.3 in the United Nations Dangerous Goods Transport Manual as an example. This test item requires a shock test machine to assess the robustness of cells and batteries against cumulative shocks. Each cell and battery(battery depending on the mass) shall be subjected to a half-sine shock of peak acceleration of 150 g and pulse duration of 6 milliseconds. Alternatively, large cells or large batteries(batteries depending on the mass) may be subjected to a half-sine shock of peak acceleration of 50 g and pulse duration of 11 milliseconds. Each cell or battery is required to suffer three shocks in the positive direction and three shocks in the negative direction in each of three mutually vertical mounting positions for a total of 18 shocks.

Half-sine wave for UN38.3 shock test

If you want to browse more devices on lithium-ion battery safety testing, please click HERE.

Test Standards

UN 38.3, IEC 62133, UL 1642, UL 2054, IEC 60068-2-27 (Suitable for cells and batteries)

MIL-STD-202F, IEC-68-2-27, MIL-STD-883E, MIL-STD-810F, GJB150, ISTA, UL, etc.

Main Technical Parameters

Mechanical Shock Test Machine Structure Description

AMADE TECH shock test system comprises a specimen mounting platform, lifting system, braking system, buffering system, waveform generator, acceleration sensor, measurement system, control system, etc.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AMADE TECH sales specialists will respond within one working day.