Battery Impact Testing Machine China Manufacturer

Lithium-ion battery impact tester is intended to simulate the impact of a cell or battery block by a heavy hammer in a free fall from a specified height. The safety performance of the cell or batteries can be judged by observing whether the sample catches fire and explodes.

Unintentional impacts of batteries during daily use or transport are a foreseeable situation. An unqualified battery may cause an internal short circuit after being hit and cause the battery to catch fire or explode.

In the international testing regulations for the transportation of dangerous goods, it is stipulated that cylindrical batteries such as 18650 cells should be subjected to a free-fall impact test with a weight of 9.1 kg. The UL lithium battery safety standard is also required to perform an impact test. Secondary lithium cells and batteries in industrial applications also require impact testing.

The battery Impact testing machine is one of the important members of lithium-ion battery safety testing devices.

Test Standards

- UN 38.3

- IEC 62133

- IEC 62619

- UL 1642

| Model | AT-L5008 |

| Impact Mass | 9.1 kg |

| Impact Height | 0 ~ 1000 mm adjustable (Usually 610 mm) |

| Height Presentation | Altimeter LED display or color touch screen display |

| Height Accuracy | ±1 mm |

| Impact Mode | Lift the hammer to a specified height and release it. The hammer falls freely in the vertical direction without tilting and shaking. |

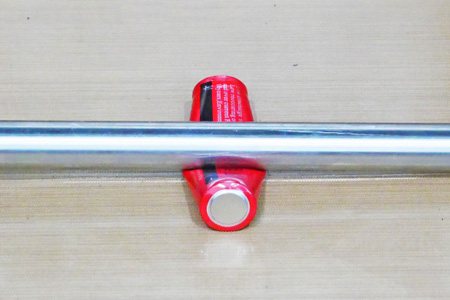

| Bar | 316L stainless steel with the diameter of 15.8 mm |

| Lifting Method | Electromotive |

| Venting & Pressure Relief Port | Available |

| Power Supply | AC 220V±10%, 3.5 A, 1 phase, 700 W or AC 110 V |

A weight of specified mass hits the sample in free fall from a specified height. The weight must not be shaken as it falls. After the impact is completed, the sample is qualified if it does not catch fire and does not explode.

Features of Battery Impact Testers from AMADE TECH

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AMADE TECH sales engineers will respond within one working day.