Horizontal Wire Pull Tester China Supplier & Manufacturer

This horizontal wire pull tester is intended to determine the pull-off strength of various wire/cable crimped terminals, joints, connectors, soldering points, etc.

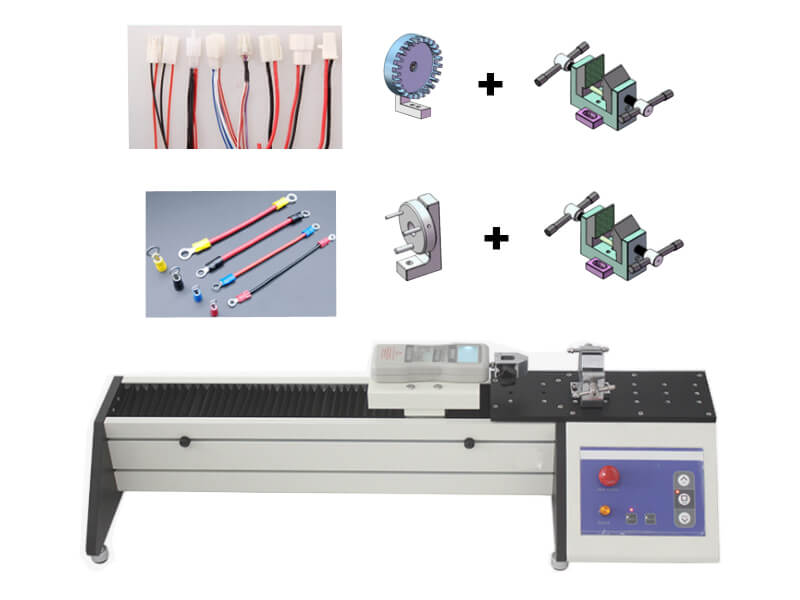

The cable pull tester is mainly composed of a test stand, a digital push-pull force gauge, a stationary grip, and a movable fixture.

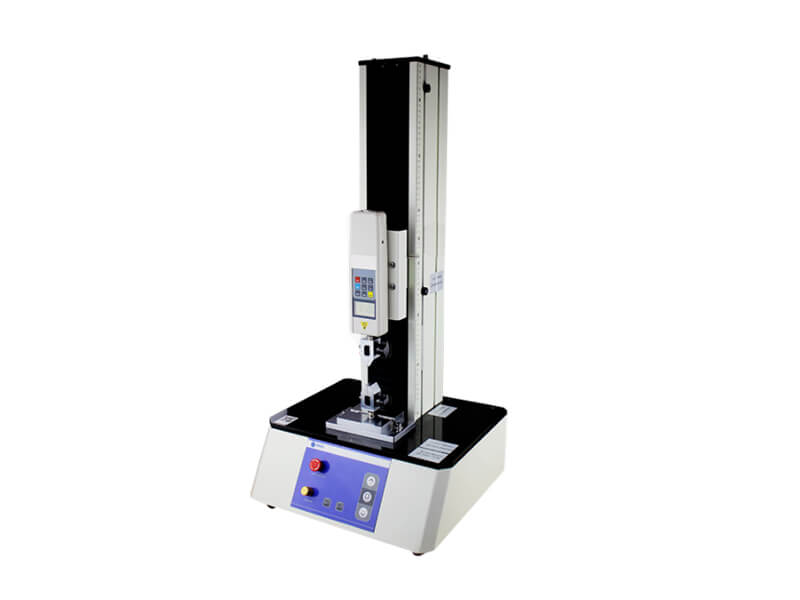

Unlike our common vertical pull tester machines, the test stand of this pull tester is horizontal. There are some significant advantages. First, the horizontal style has more ample space for pulling up. Second, it can effectively reduce the influence of the weight of the sample on the test result during the test. Third, the operator can mount and remove the sample more conveniently.

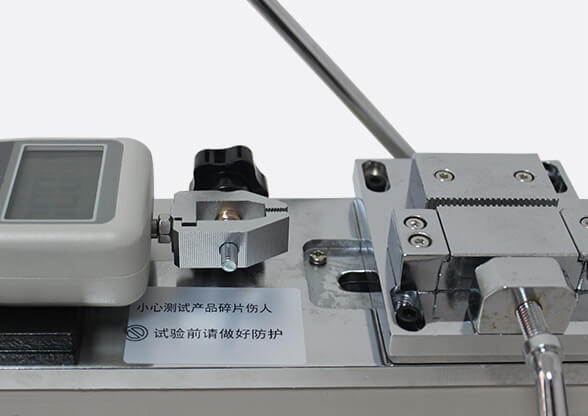

Each Horizontal Wire Pull Tester is equipped with a pair of clamps, including a movable clamp controlled by the lever and a stationary clamp connected to the push-pull gauge. The movable clamp is to grip the terminal to be tested, and the stationary clamp is to fix the other end of the specimen. The saw-toothed jaws of clamps enable the specimen to be held firmly.

This wire terminal pull tester can test various wire terminal samples by matching different fixtures. In addition to the standard grip, we can also tailor a variety of other fixtures to help you complete the test according to the characteristics of your sample, such as the connector pull-off test and wire crimp pull test.

The terminal end of the specimen is gripped in the stationary fixture, and the other end is fixed in the movable fixture, keeping the wire sample on the same horizontal axis and in a slightly taut state. The lever is pulled slowly to stretch the specimen until it breaks. The real-time force value is displayed on the screen, and the peak value is recorded as the pull force of the specimen.

| Model | AT-U2-51 | ||||||||

| Capacity | 2 N | 5 N | 10 N | 20 N | 50 N | 100 N | 200 N | 500 N | 1000 N |

| Resolution | 0.001 N | 0.001 N | 0.01 N | 0.01 N | 0.01 N | 0.1 N | 0.1 N | 0.1 N | 1 N |

| Accuracy | <±1 F.S | ||||||||

| Sampling Rate | 1000 times / s | ||||||||

| Stroke | 50 mm | ||||||||

| Three Units | N / lbf / gf | Kfg / N / lbf | |||||||

| Fixtures | A pair of fixtures | ||||||||

| Dimension | 450 mm × 100 mm × 130 mm | ||||||||

| Weight | About 11 kg | ||||||||

| Accessories | Adapter, Test software and USB cable | ||||||||

Please click HERE to learn more about different types of grips and fixtures.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.