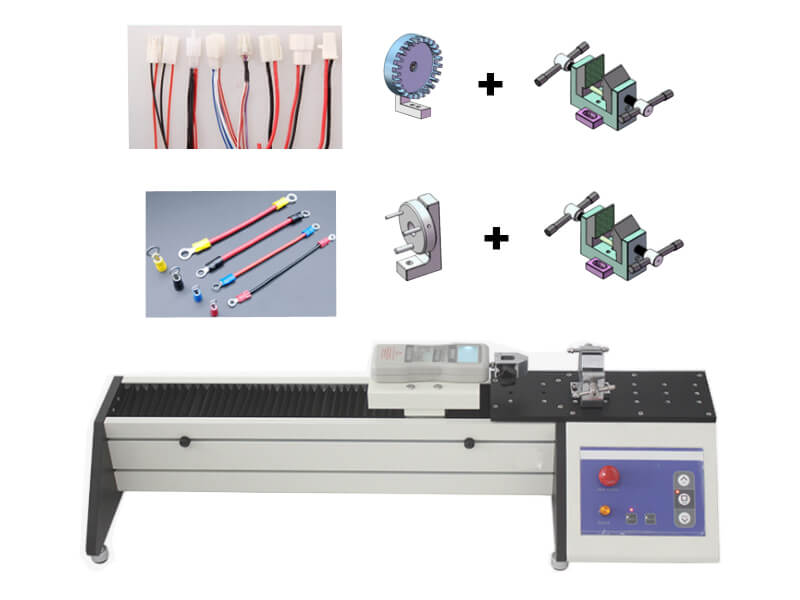

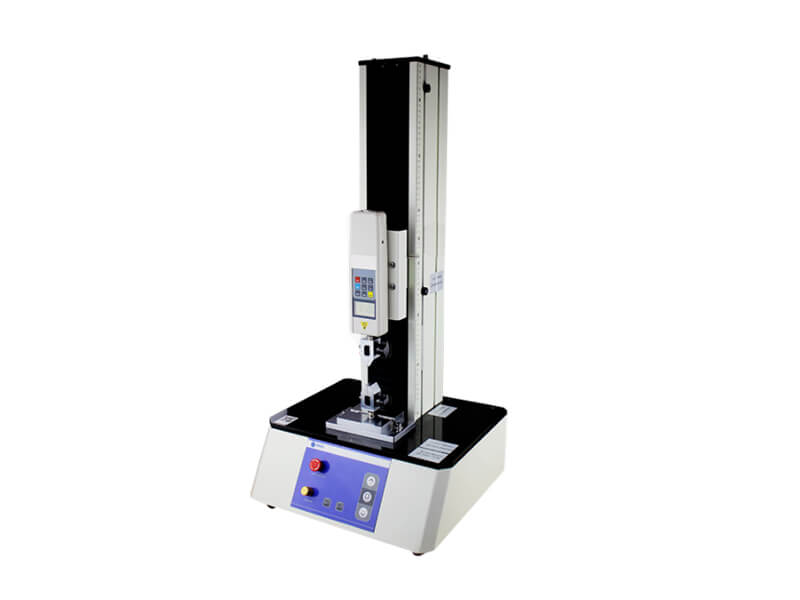

When performing the tension, compression, and torsion tests, grips and fixtures are used as core components on the tensile testing system. The below devices are compatible with all our pull / tensile / compression testing machines. The grips we can provide include but are not limited to the following. AmadeTech can provide more grips & fixtures that meet the test requirements according to your specific samples and test items. Please feel free to get in touch with us to get a targeted solution.

Wire Terminal Grips

Peel Test Fixtures

Pull / Tensile Grips

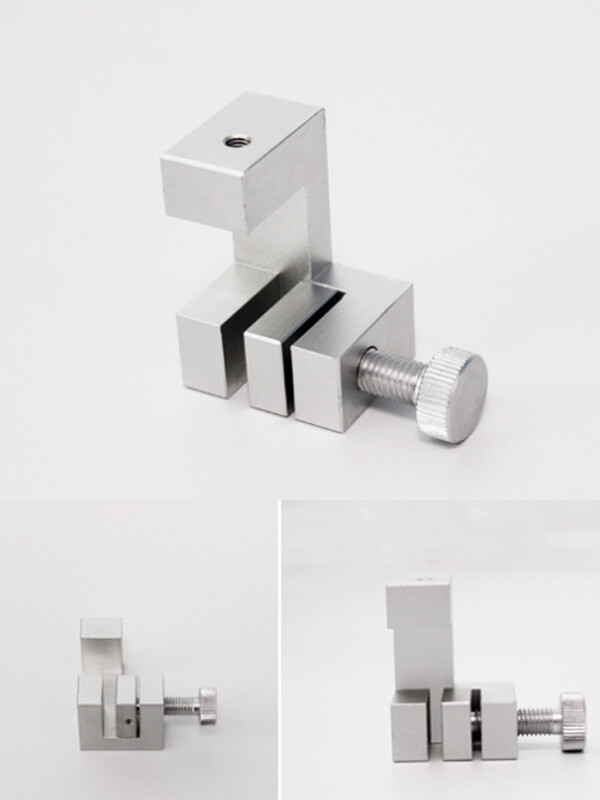

AT-U2H14

- Acceptable width of specimens – 0 ~ 25 mm

- Acceptable thickness of specimens – 0 ~ 6 mm

- 50 mm in height

- Clamping force of 500 N

- Screw holes – M6, Weight – 0.25 kg

- Particularly suitable for tensile and peeling tests of sheet materials such as plastic film, rubber, cloth, cables paper, composite materials, etc.

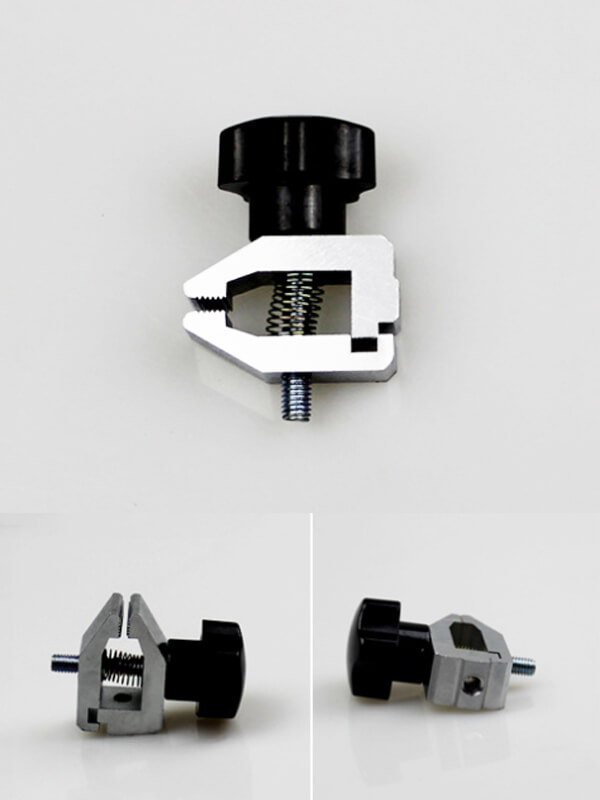

AT-U2H15

- Max. capacity of 100 N

- Acceptable thickness of specimens – 0 ~ 5 mm

- Acceptable width of specimens – 0 ~ 55 mm

- Height of grip – 50 mm

- Screw holes – M6

- Weight – 0.49 kg

- Suitable for tensile and peeling tests of sheet materials such as plastic film, rubber, cloth, cables paper, composite materials, etc.

AT-U2H21

- Max. capacity of 500 N

- Acceptable thickness of specimens – 0 ~ 5 mm

- Acceptable width of specimens – 0 ~ 65 mm

- Height of the grip – 50 mm

- Screw holes – M6

- Weight – 0.56 kg

- Suitable for tensile and peeling tests of sheet materials such as plastic film, rubber, cloth, cables paper, composite materials, etc.

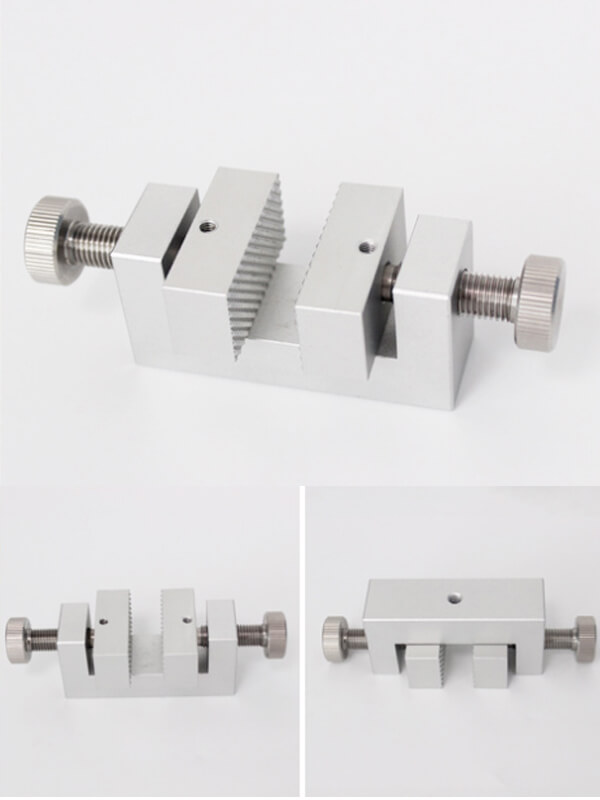

AT-U2H26C

- With serrated Jaws

- Max. capacity of 500 N

- Acceptable thickness of specimens – 0 ~ 9 mm

- Acceptable width of specimens – 0 ~ 50 mm

- Height of the grip – 35 mm

- Screw holes – M6

- Weight – 0.4 kg

- Suitable for pull and peel testing of sheet materials such as films, rubber, cloth, paper, composite materials, etc.

AT-U2H26D

- With serrated Jaws

- Max. capacity of 1000 N

- Acceptable thickness of specimens – 0 ~ 9 mm

- Acceptable width of specimens – 0 ~ 50 mm

- Height of the grip – 35 mm

- Screw holes – M6

- Weight – 0.4 kg

- Suitable for pull and peel testing of sheet materials such as films, rubber, cloth, paper, composite materials, etc.

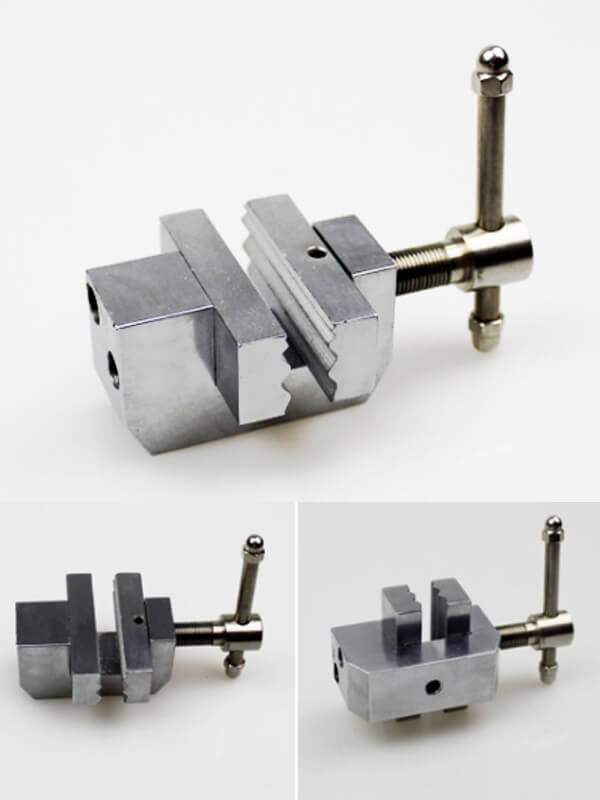

AT-U2H32

- AT-U2H31A (Flat jaws)

- AT-U2H31B (with dense teeth)

- AT-U2H31C (with raised grain)

- Max. capacity of 2000 N

- Acceptable thickness of specimens – 0 ~ 10 mm

- Acceptable width of specimens – 0 ~ 55 mm

- Screw holes – M12

- Weight – 0.5 kg

- Suitable for tensile testing of sheet materials such as packaging tapes, plastic, films, rubber, cloth, paper, wire, composite materials, etc.

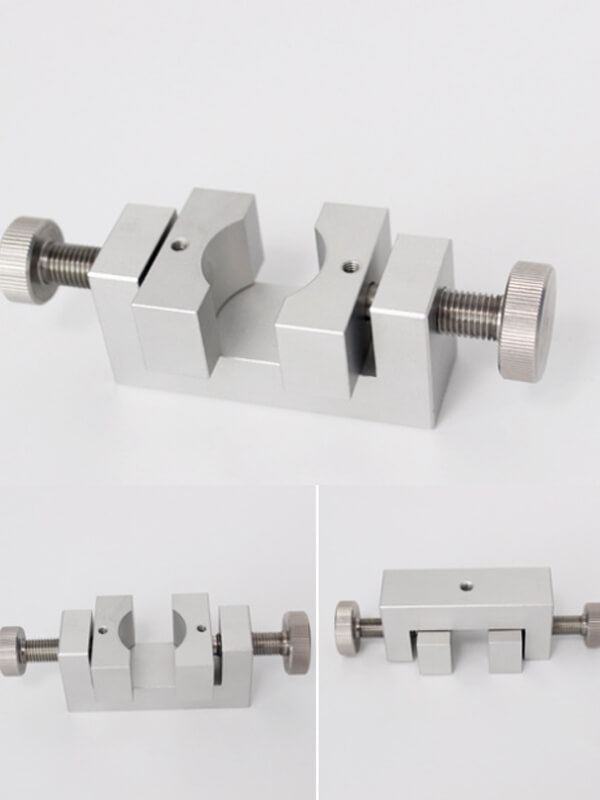

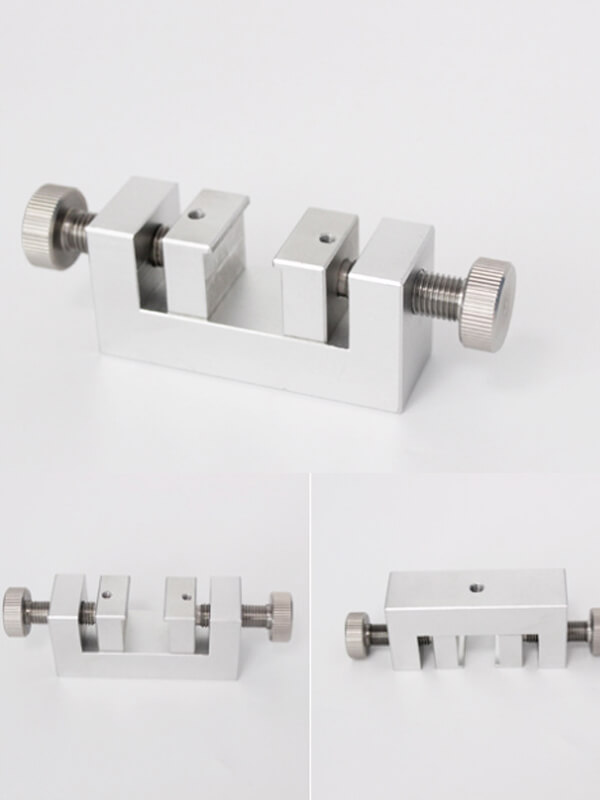

Parallel-jaw Vises

Compression Test Fixtures

Standard Attachments for the Push Pull Gauge

Send an Inquiry Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.

Related Products

AmadeTechAdmin2022-11-24T08:51:41+00:00

AmadeTechAdmin2022-01-05T08:55:16+00:00

AmadeTechAdmin2022-01-05T08:47:29+00:00

AmadeTechAdmin2022-01-10T09:04:40+00:00