Lithium-ion Battery Crushing Test Machine China Manufacturer and Supplier

Lithium-ion Battery Crush & Nail Penetration Test Equipment is used to simulate the mechanical abuse, including the crushing and nail penetration exerted on the lithium-ion cells/batteries, to determine their safety performance when subjected to the same conditions in practical applications.

In particular, the crush test is essential for battery safety testing, and you can almost see it in all mainstream lithium-ion battery safety testing standards.

AMADE TECH lithium-ion battery tester is a 2-in-1 dual-purpose testing equipment thanks to the replaceable test fixtures and attachment inside the chamber. Before the test, it allows you to mount crushing plates or crushing heads in different sizes and shapes to perform the crushing test or mount the corresponding needles and fixtures to perform the nail penetration test. The whole disassembly and assembly process is effortless and convenient.

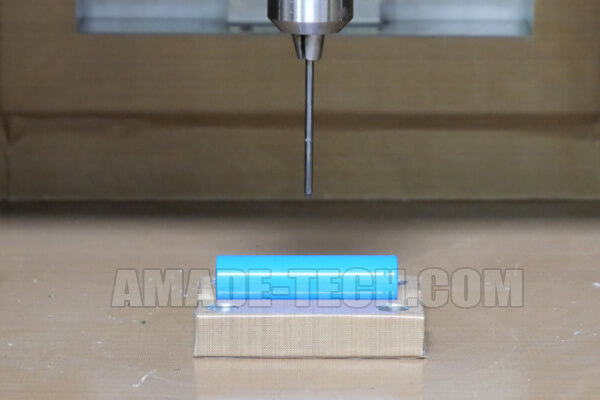

Pressing plates for crush test

Needle for nail penetration test

AMADE TECH has designed different types of crush & nail penetration test machines according to international test standards for cells, modules, and battery packs.

20 kN cell crush & nail penetration tester

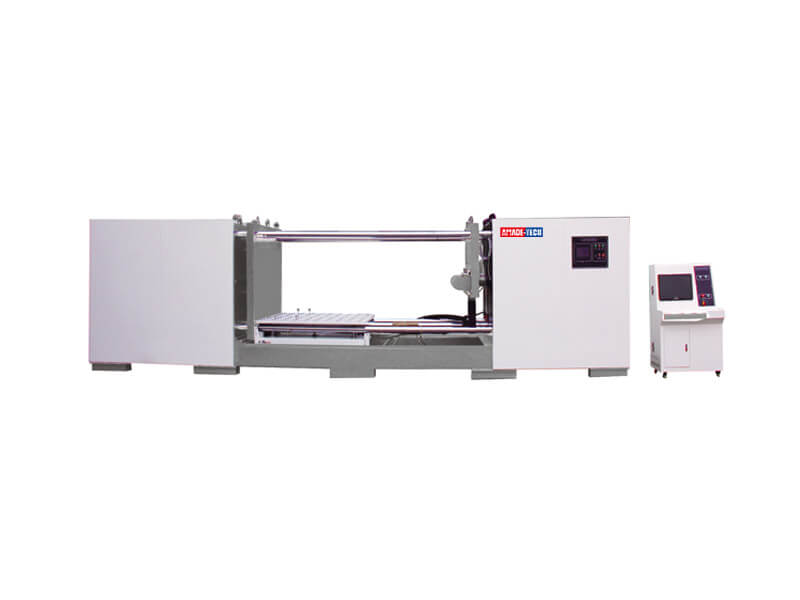

200 kN battery module/pack crush & nail penetration tester

1000 kN battery pack crush & nail penetration tester

Our conventional crush & nail penetration test equipment has a common feature: the test space adopts an enclosed box structure. It is because unqualified battery samples may be encountered during testing, which means that an internal short circuit may occur and cause a fire or explosion. This box-type structure can effectively isolate the testing area from the external laboratory environment. In the event of a fire or explosion, it can control and limit the flame, smoke, and shock waves within the box as much as possible, thereby protecting surrounding people or equipment from hurt. Apart from this, we have also equipped the equipment with safety features such as pressure relief vents, explosion-proof chains, smoke vents, and even fire extinguishers if necessary.

For the crushing test of large-volume battery packs, we can also supply unconventional horizontal open-type testing machines to provide greater crushing force and test space.

Crushed cells

Crushed battery pack

Battery pack crush test

Penetrated cells

Control System

We configure each battery crush & nail penetration test equipment with a computer pre-installed with specialized testing software. With the support of PLC, precise control and real-time data display of parameters such as applied pressure, specimen deformation, specimen voltage, and specimen surface temperature can be achieved. You are allowed to preset the desired parameter values based on the standard’s requirements. The machine automatically ends the test when the test conditions reach any of the preset values.

Attachments & Fixtures

| Test Types | Regular Auxiliary Devices |

| Crushing test | 150 mm diameter flat plate

R75 mm semi-circular bar Hemispherical head with a diameter of 150 mm Crush plate composed of 3 pcs of R75 mm half cylinders R75 mm round bar |

| Nail penetration test | Tungsten steel needles in corresponding sizes |

| Model | AT-L5001 |

| Force Applied Range | 0 ~ 20 kN |

| Crushing Speed | 1.5 cm / s, the speed range: 0.01 ~ 900 mm / min adjustable (0.01 ~ 1.5 cm / second) |

| Drive Method | Servo motor and driver |

| Crush Travel | 0 ~ 300 mm |

| Test Space | More than 300 × 300 × 300 mm (W x D x H) |

| Force Accuracy | +/- 0.5% |

| Crush Retention Time | 0 ~ 9,999 Sec adjustable |

| Control Mode | Controlled by professional testing software on the computer |

| Battery Crush Test Conditions | During the test, as long as any one of the following conditions is met (whichever comes sooner), the device relieves pressure and ends the crush test (based on UN38.3 & IEC 62133-2):

1) Applied crushing force reaches (13 ± 0.78) kN; 2) The voltage of battery drops by at least 1/3 or 100 mV; 3) The cell is deformed by 1/10 or 50% of its original thickness. |

| Test Software Features | a) It owns 1 channel of voltage acquisition

Voltage acquisition resolution: 5 mV Voltage acquisition range: 0 ~ 10 V b) The test software can monitor the voltage change, the pressure on the sample and the deformation of the sample in real time. c) The function for battery surface temperature acquisition is optional with additional cost. |

The cell/module/battery pack sample is placed on an electrically insulating platform, and then a specific force is applied to the sample through the moving crushing head. The conditions for releasing the pressure are different according to different test standards. Mainly as follows:

- The initial size of the specimen is reduced to a specified percentage by crushing.

- The applied pressing force reaches a specified value (kN). (and maintained for a specified duration if required.)

- The voltage of the specimen drops to a specified value.

- The surface temperature of the specimen drops to a specified value (if required).

These conditions can be controlled individually or in combination.

- UN 38.3

- IEC 62133

- IEC 62660-2

- IEC 62660-3

- UL 1642

- EN 50604-1

- ISO 12405-3

- SAE J2462

- GB/T 38415, etc.

Li-ion Battery Crush & Nail Penetration Tester Features

Learn More about the Crush Test

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AMADE TECH sales specialists will respond within one working day.