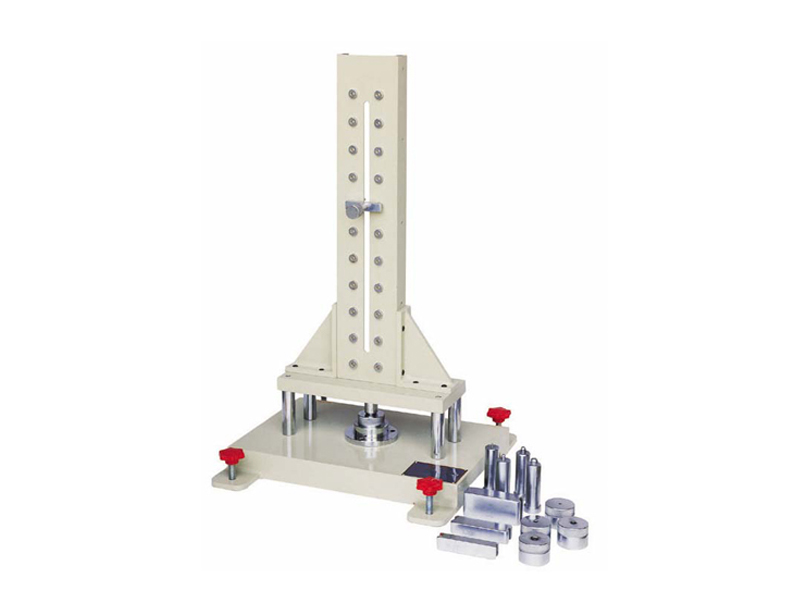

Automatic Notch Cutting Machine China Supplier

Motorized Notch Cutter is a sample preparation equipment specially used for producing V & U-shaped notches on non-metallic materials such as plastics used as specimens to determine impact energy and impact toughness using the IZOD impact testing machine and the Charpy pendulum impact tester.

This automatic V notch cutting machine is power-driven, owning a high work efficiency of as many as 60 pcs notches to be cut per 10 minutes. A milling cutter is equipped to cut a V-shaped notch on one side of the test piece. Up to 20 test pieces are clamped together in a bundle and notched in one cut. Different cutters are provided for different materials and notch radius in the notch base.

AMADE V notch cutter is in compliance with ISO and ASTM standards. From the design to selecting raw materials and the assembly process, we are dedicated to producing the safest, durable and reliable machine for our clients. As the accuracy of the positioning of the notch has an impact on the measured energy, AMADE Notch cutting machine becomes a necessary auxiliary device before conducting IZOD and Charpy impact tests.

Test Standards

ISO 179 Plastics – Determination of Charpy Impact Properties

ISO 180 Plastics – Determination of Izod Impact Strength

ASTM D – 256 Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics

ASTM D – 6110 Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics

INQUIRE

Main Technical Parameters

| Model | AT-P6007 |

| Travel of Work Platform | > 160 mm |

| Feed Velocity | 30 mm / min |

| Notch Type | A: 45° ± 1° R = 0.25 ± 0.025 mm

B: 45° ± 1° R = 1.0 ± 0.025 mm C: 45° ± 1° R = 0.1 ± 0.02 mm C1: 0.8 ± 0.1 mm C2: 2.0 ± 0.2 mm |

| Feed Volume | Depends on standard selected |

| Dimension | 600 mm × 270 mm × 300 mm |

| Power Supply | 220 V AC 50 Hz, single phase 3-wire or specified |

| Weight | 32 kg |

Notch cutting machine Features

- This charpy v notch cutter is equipped with an electric drive to save much human labor during use.

- Fitted with a precision motor to actuate the machine smoothly and ensure durability and stability.

- Configured with a top-quality single-tool milling cutter to ensure easy notch production.

- Quick-action clamping device enables test pieces to be fastened quickly.

- The notch depth is easy to set manually.

- As many as 20 pieces of specimens can be clamped and processed at the same time.

- Complies with various international standards such as ISO, ASTM, DIN.

- Equipped with a transparent acrylic protective cover to protect operators during use.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.