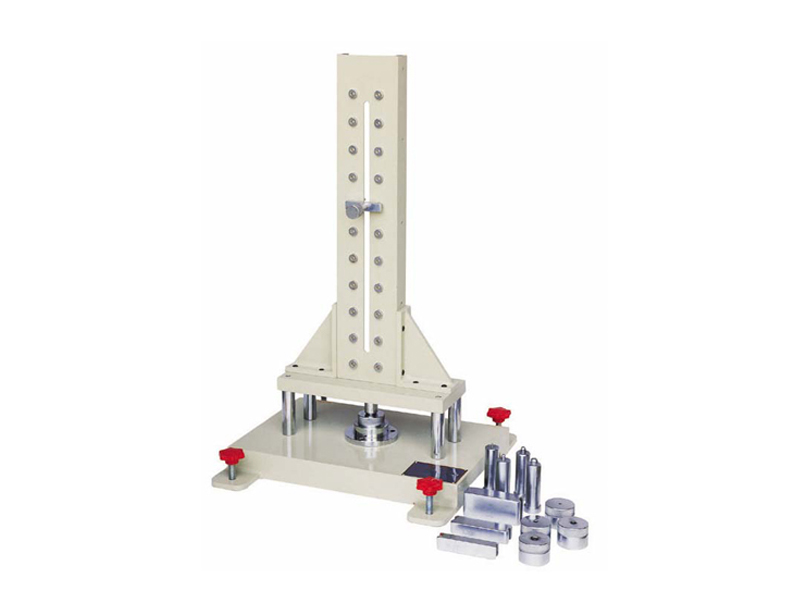

Charpy Pendulum Impact Tester China Manufacturer

Impact strength is often used to evaluate the ability of materials to resist impact or to judge the brittleness or toughness of materials, which is an important performance index of plastic materials in engineering applications. It reflects the ability of different materials to resist damage caused by high-speed impact. When measuring the impact strength of plastics, the commonly used test methods include the IZOD impact method and the Charpy impact method. There are two types of notched impact and unnotched impact in these two methods. What we will introduce here is the Charpy impact tester.

Charpy Impact Tester is intended to determine the Charpy impact strength of hard plastics, fiber reinforced composites, glass fiber reinforced plastics, ceramics, asbestos and other non-metallic materials under specified conditions. It is capable of mastering the behaviour of stipulated kinds of test pieces under the impact conditions and estimating the brittleness or toughness of test pieces within the limitations inherent in the test conditions. The determination of comparative data from similar kinds of material is available via this equipment. It is an ideal testing instrument for manufacturing industries, research and development institutions, colleges and universities, and quality inspection organizations.

Before the test, a simple calibration of the instrument without placing the specimen is conducted for the resistance of friction and wind. The hammer is released electronically by a solenoid during the test under the operator’s control. Different impact velocities of 2.9 m/s and 3.8 m/s are available by choosing different types of pendulum ranging from 1 J to 50 J. A PLC controller coupled with a touch screen facilitates the parameter setting and data monitoring, including impact energy, impact velocity and sample size, etc.

INQUIRE

Test Principle

A prepared test piece is supported near its ends as a horizontal beam, and the separation between the sample supporting blocks is adjustable according to the test requirements. A specified pendulum is raised to a given height and allowed to hit the center of the notched or unnotched specimen singly. The impact energy is measured automatically when the impact occurs.

Test Standards

ISO 179-1, GB / T 1043-2008, JB / T 8762-1998, GB / T 1451-2005, GB / T18743-2002, etc.

Main Technical Parameters

| Model | AT-P6006 | ||

| Pendulum Energy | 1 J, 2 J, 4 J, 5 J | 7.5 J, 15 J | 25 J, 50 J |

| Control Method | PLC + Color touch screen | ||

| Pendulum Angle of Elevation | 150° | ||

| Impact Velocity | 2.9 m/s | 3.8 m/s | 3.8 m/s |

| Center Distance of Pendulum | 230 mm | 395 mm | 395 mm |

| Angle Resolution | 0.01° | ||

| Energy Resolution | 0.01 J | ||

| Spacing of Support Blocks | 40 mm, 60mm, 70mm, 95mm (or customized) | ||

| Supporting Blade Radius | R 1 mm | ||

| Impact Blade Angle | 30° | ||

| Impact Blade Radius | R 2 mm | ||

| Power Supply | 1 Phase, 220V 50Hz or specified | ||

Charpy Impact Testing Machine Features

- Pendulum is made from new carbon fiber material with better rigidity to achieve a vibration-free impact test.

- The energy loss caused by friction and wind resistance is automatically corrected to improve the accuracy of the test.

- Controlled by PLC, configured with a high precision encoder to make the test data more accurate and stable.

- All parameters and results, including impact energy, impact strength, elevated angle, mean value, etc., can be presented through an LCD.

- Compatible with test specimens with a notch and without a notch.

- Capable of conducting tests of edgewise impact, flatwise impact, perpendicular impact and parallel impact.

- The span between specimen supports can be adjustable, including 40mm, 60mm, 70mm, 95mm based on different requirements.

- Different pendulums in different energies from 1 J to 50 J suit various testing needs.

- It contains two types of impact velocity incorporating 2.9 m / s & 3.8 m / s.

- The units of J/m, KJ/㎡kg-cm/cm are available and final results can be calculated automatically.

- 24 groups of test data can be saved and averaged.

- Configured with a built-in thermal printer to print test results.

- A closed protective fence in the direction of the pendulum impact is equipped to prevent the broken sample from hurting people around the machine.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.