Oxygen Index Test Apparatus China Supplier

Limiting Oxygen Index Tester, abbreviated as LOI tester, is used to measure the minimum concentration of oxygen required to support the flaming combustion of small vertical testing materials in a flowing mixture of oxygen and nitrogen under specified test conditions.

The instrument is mainly suitable for the flammability test of solid, laminated, foam, plastic, fabric, film, and other materials. It can not only be used as a device for identifying the flammability of polymers but also as a powerful testing tool for laboratories to study flame-retardant formulations and develop flame-retardant materials.

Compliant Test Standards

- ASTM D2863, ISO 4589-2, NES 714, JIS 7201, BS 2782, GB/T 2406.2, etc.

- ISO 4589-3 (Please inquire separately for the apparatus for the elevated-temperature test)

Test Principle

A small test piece is supported vertically in a mixture of oxygen and nitrogen flowing upward through a transparent cylindrical chimney. The upper end of the test piece is ignited, and the subsequent burning behavior of the test piece is observed to compare the period for which burning continues, or the length of the test piece burnt, with specified limits for each burning. Through testing a series of test pieces in different oxygen concentrations, the minimum oxygen concentration is determined.

Request Quote

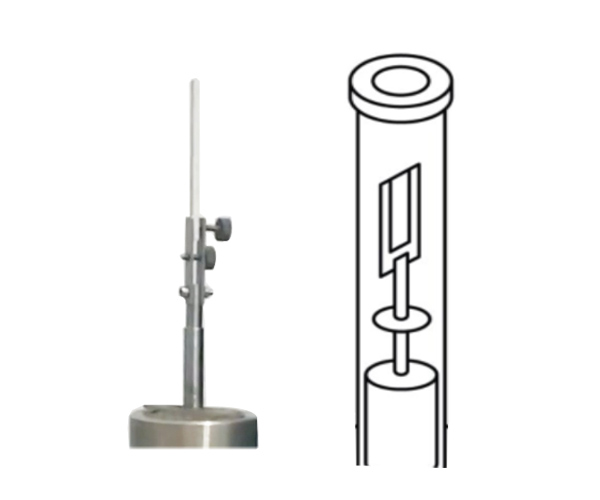

Test Chimney

AmadeTech oxygen index tester features a cylindrical test chimney of 450 mm in height and 75 mm in inside diameter made of silica glass with excellent heat-resistant performance to provide a combustion space for testing. There is an overhead cap converging to an outlet of 40 mm diameter at a level about 10 mm above the top of the cylindrical chimney to generate an exhaust velocity of at least 90 mm / s. A gas mixing chamber made of stainless steel erected on the base allows the chimney to sleeve into it to achieve its vertical standing.

To evenly distribute the gas mixture entering the chimney, we offerglass beads of 4.5 mm in diameter for stuffing the mixing chamber at the bottom of the chimney. A temperature measuring device is available inside the chimney to allow you to keep track of test temperature.

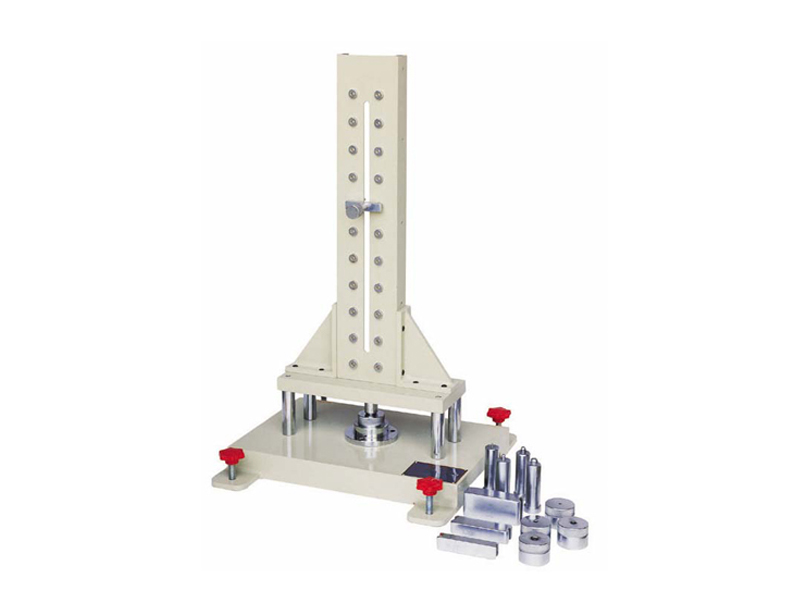

Specimen Holders

AmadeTech LOI tester comes with two types of specimen clamping apparatuses to support a specimen vertically in the center of the chimney. One is a regular vertical specimen holder to support testing materials that are self-supporting in the form of vertical bars or sheets up to 10.5 mm thick, and the other is a folk-shaped support frame with two vertical edges made of stainless steel to hold non-self-supporting test specimens in the form of flexible sheets or films. Both are removable and interchangeable in accordance with test requirements.

Flame Igniter

A copper tube of (2±1) mm in inside diameter is provided by AmadeTech to allow you to connect it to the gas canister (Due to dangerous goods transport restrictions, you may need to prepare your own gas supplies in compliance with requirements of the standard you follow.) The end of the tube is required to be inserted into the chimney to apply to the test specimen a flame. (The flame height needs to be adjusted to (16±4) mm when the tube is vertical within the chimney at the set oxygen concentration.)

Technical Parameters

| Model | AT-P6012 |

| Material of test chimney | Quartz glass |

| Chimney dimensions | 450 mm high and 75 inside diameter |

| Bottom gas velocity | (40±2) mm/ s |

| Top gas velocity | (90±10) mm / s |

| Oxygen concentration | Measuring range: 0 ~ 100% (by digital display) |

| Measuring resolution: 0.1% | |

| Test accuracy: Grade 2.5 | |

| Gas input pressure | 0.25 ~ 0.5 Mpa Adjustable |

| Oxygen and nitrogen mixed gas inlet | Including pressure stabilizing valve, flow regulating valve and mixing chamber |

| Rotameter | Mixture gases (Oxygen and Nitrogen can be shown separately) |

| Measuring range of flow meter | 2.5 ~ 25 L / Min |

| Display resolution of flow meter | 0.5 L / Min |

| Glass bead dimensions | 4.5 mm in diameter and stuffing height 95 mm (adjustable) |

| Oxygen concentration sensor | Imported from UK |

| Flame igniter | By Handle-held & electronic ignition |

| Flame fuel: propane whose purity not less than 98% | |

| Copper tube with diameter (2±1) mm | |

| can adjust the flame Injection length downward to (16±4)mm | |

| Timer accuracy | ±0.1 s / h |

| Specimen holders included | One for self-supporting specimens

The other for flexible specimens |

| Gas supplies | Oxygen and nitrogen not less than 98% (mass fraction) pure (Prepared by clients) |

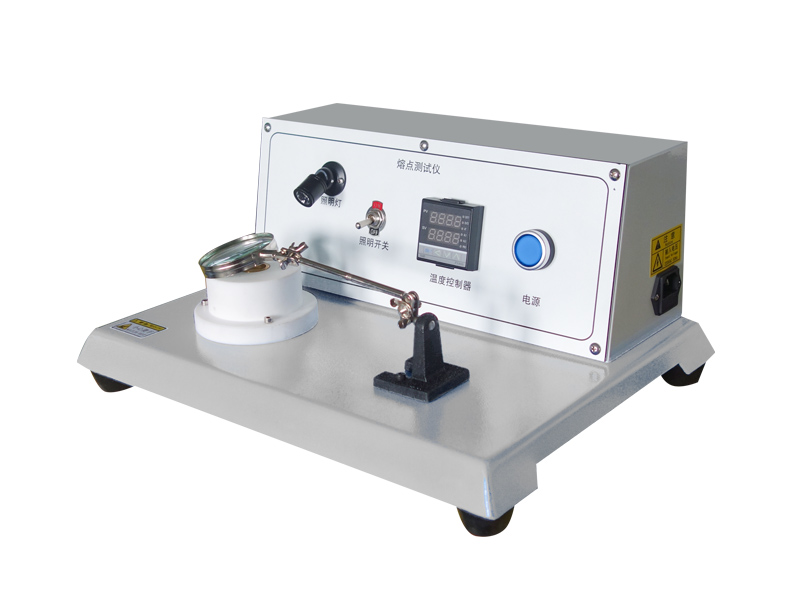

| O2+N2 Temperature control | Automatic control at (23±2)℃ |

| Power supply | AC 220 V or 110 V, 100 W |

| Machine dimensions | 630 (L) x 350 (W) x 655 (H) |

| Safety protection devices | Overload protection of power supply and control loop, short circuit protection |

Limiting Oxygen Index Tester Features

- The LOI tester has a reasonable structure design of the instrument, easy operation, and maintenance.

- The control box is processed by CNC, and the surface is sprayed with high-quality baking paint, which brings beautiful anti-rust and anti-corrosion effects.

- Equipped with two pressure gauges to provide oxygen and nitrogen output pressure presentation, the air pressure can be adjusted through the corresponding regulating valve.

- The supply of oxygen and nitrogen flows can be adjusted separately by turning the corresponding knob.

- Provided with 2 specimen holding devices for self-supporting specimens and flexible specimens.

- Fitted with a top-quality oxygen analyser imported from the UK, enabling accurate judgment and good reproducibility.

- The oxygen concentration is displayed on a digital screen.

- The real-time temperature inside the chimney can be shown on the digital screen.

- The mixer at the bottom of the combustion tube makes the incoming mixed gas evenly distributed, aided with glass beads to mix oxygen and nitrogen evenly.

- Configured with various safety protection devices for guarding test safety.

FAQs

Leave Your Message Here

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales engineers will respond within one working day.