Orientation Drop Tester Machine China Supplier

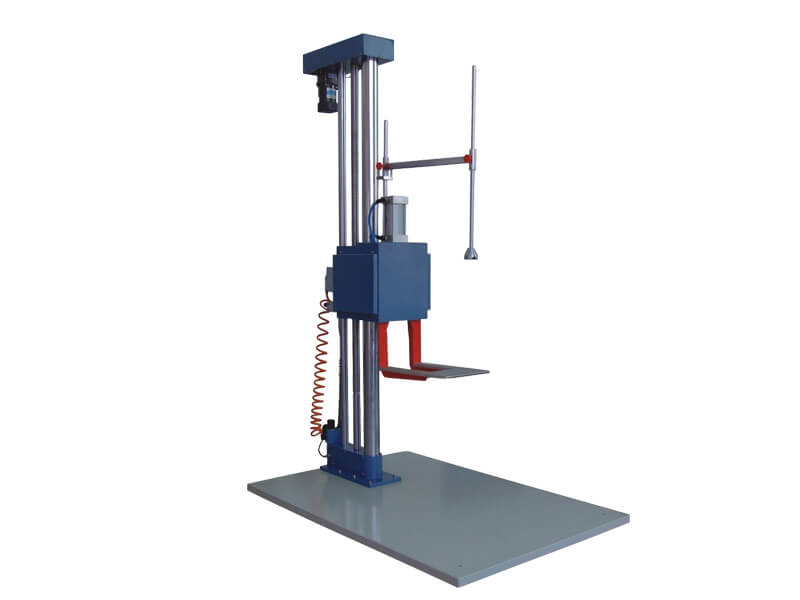

Multi-orientation Drop Tester is used for drop impact test on small electronic products in designated direction and specified posture. It is a practical and effective drop test equipment to determine the impact resistance of electronic products when they are accidentally dropped to the ground.

The orientation drop test machine is suitable for small electronic products like mobile phones, E-books, IPAD, etc. Especially widely used in the mobile phone manufacturing industry.

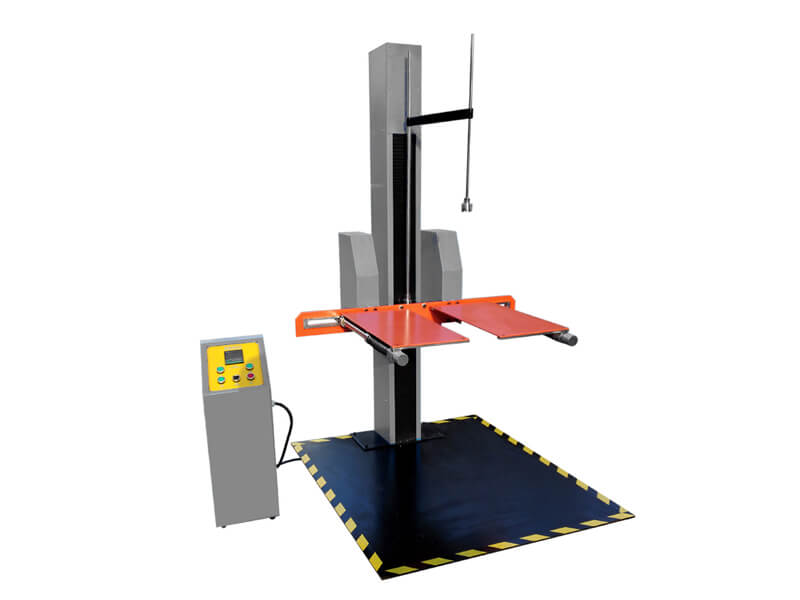

This drop test machine is allowed to be configured with different holding devices to achieve directional drop tests on the edges, corners, and surfaces of the specimen through different angles. The specimen can be lifted to a specified height and dropped to impact the pre-placed floor. During the descent, the specimen will be automatically released at a specified height such as 300 mm to guarantee that the test piece is close to its original posture at the moment of the impact. In addition to the directional drop test, this drop tester machine is also suitable for the free-fall drop test.

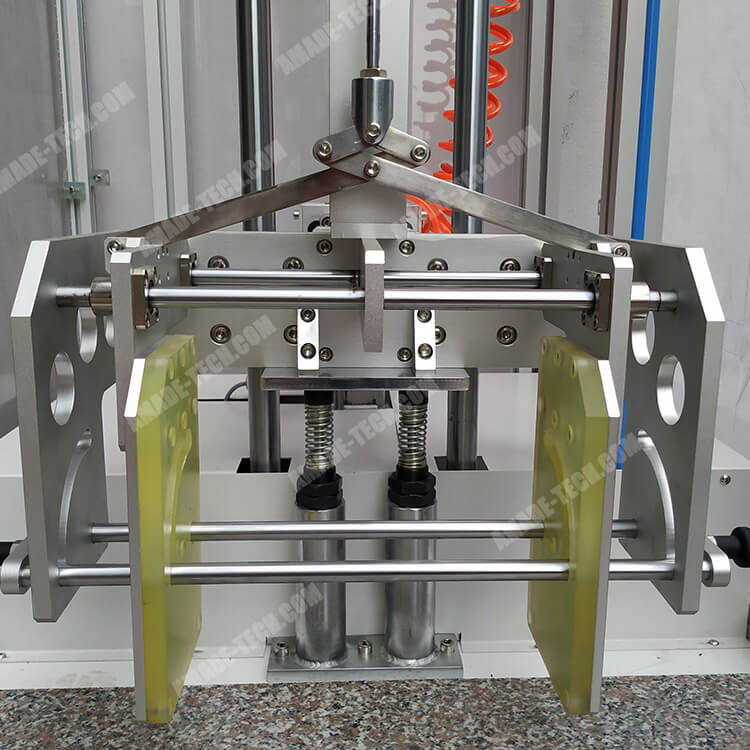

There are mainly two types of fixtures that are available to be fitted to this orientation drop tester. One is the pneumatic clamping device driven by cylinders. The specimen can be conveniently clamped and released by two parallel clamping plates under control. The distance between clamping plates is adjustable to accommodate specimens of different dimensions and shapes. The other is the pneumatic assembly with multiple vacuum suction cups. They can suck the specimen tightly and achieve the drop test at different angles. The vacuum suction cup is suitable for the drop test of bare mobile phones, tablets, and other electronic products. You are required to prepare the air source to ensure the fixture can work normally.

| Model | AT-D3001 |

| Product | Orientation drop tester |

| Max. Test Height | 300 ~ 1800 mm (2000 mm customized) |

| Max. Drop Product Weight | 1 / 2 kg |

| Min. Drop Height | 300 mm |

| Max. Size of the Acceptable Specimen | Regular 150 × 150 mm (The bigger sizes need to be customized) |

| Drop Posture | On edges, corners, surfaces at 0°, 45°, 90° or other desired angles |

| Drop Angle Error | about 1° ~ 3° |

| Counter | 0 ~ 999,999 times (can be set) |

| Sample Holding Method | Sucked or clamped by a pneumatic mechanism (can be customized) |

| Vacuum Adsorption Switching Mode | Three vacuum chucks can be switched electronically

(independently) |

| Parameter Setting | The drop height and adsorption height can be preset, and the number of drops is displayed and supports being cleared |

| Safety Door Protection Function | Fully enclosed transparent acrylic plates to protect operators |

| Control Mode | PLC programming touch screen control (drop velocity is displayable) |

| Drop Floor | A3 steel plate (The acrylic board, wooden board, marble board and other materials can be used) |

| Drop Method | Pneumatic drop / Free fall |

| Lifting Method | Automated lifting |

| Air Source | ≥ 0.5 Mpa |

| Power supply | Power supply 1∮, 220 V AC ± 10 %, 50 / 60 Hz or specified |

- JIS C 0044

- IEC 60068-2-32

- YD/T 1539-2006, etc.

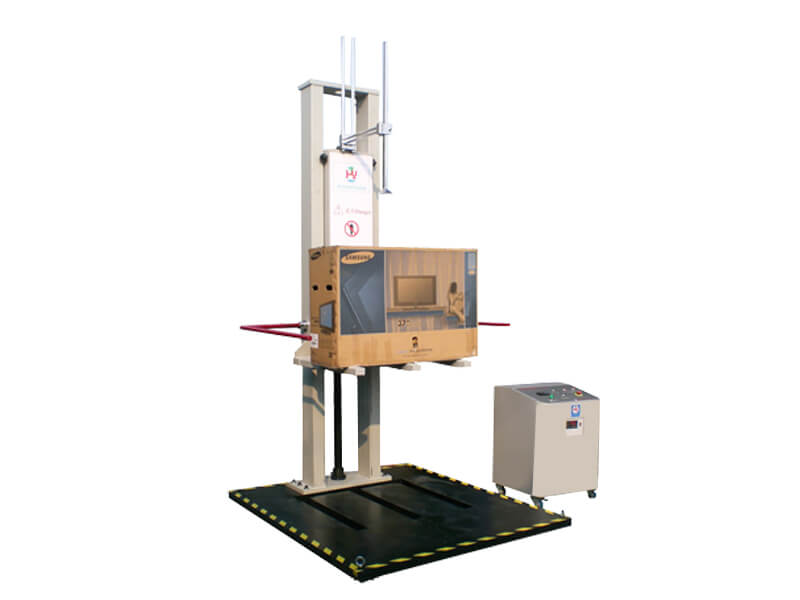

There are usually have three other drop testing machines used for drop tests of electronic products, including Free Fall Drop Tester, Rotating Drum Drop Tester, Package Drop Tester.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.