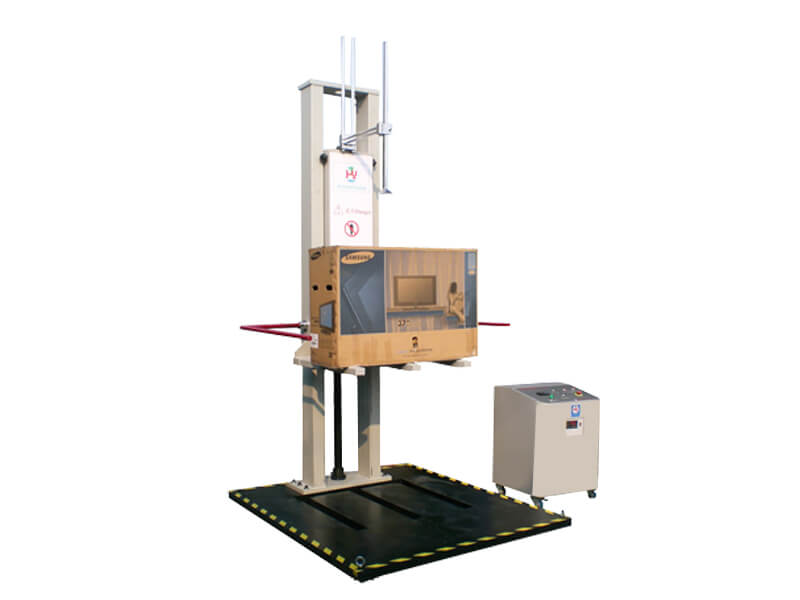

Package / Carton Drop Test Machine China Manufacturer

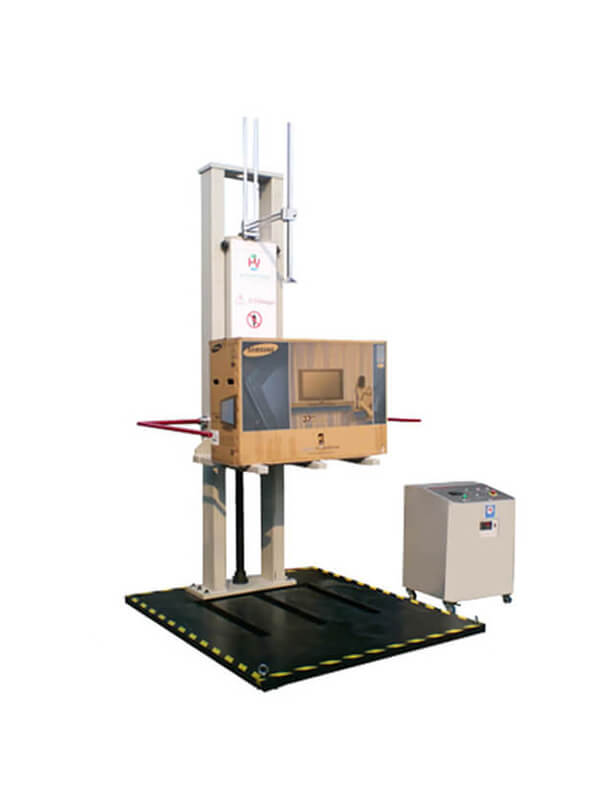

Package Drop Tester is used to conduct a free fall test on a complete, filled transport package. It simulates the drop of the corrugated box hitting its side, edge, or corner from a specified height through a given angle to determine whether the package or stuff inside can withstand the impact force when the drop occurs in the practical scene.

In order to get the test results nearest to the actual conditions, test sample packages filled with intended, simulated, or dummy contents are required.

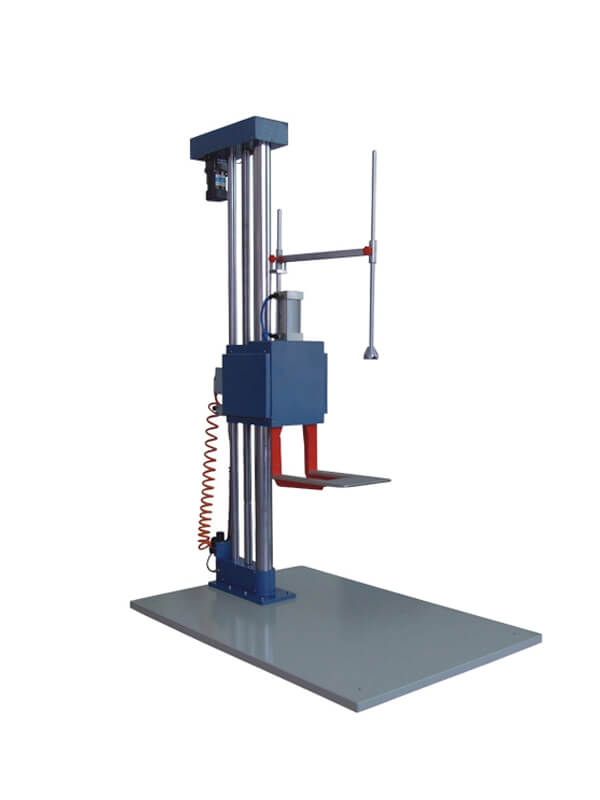

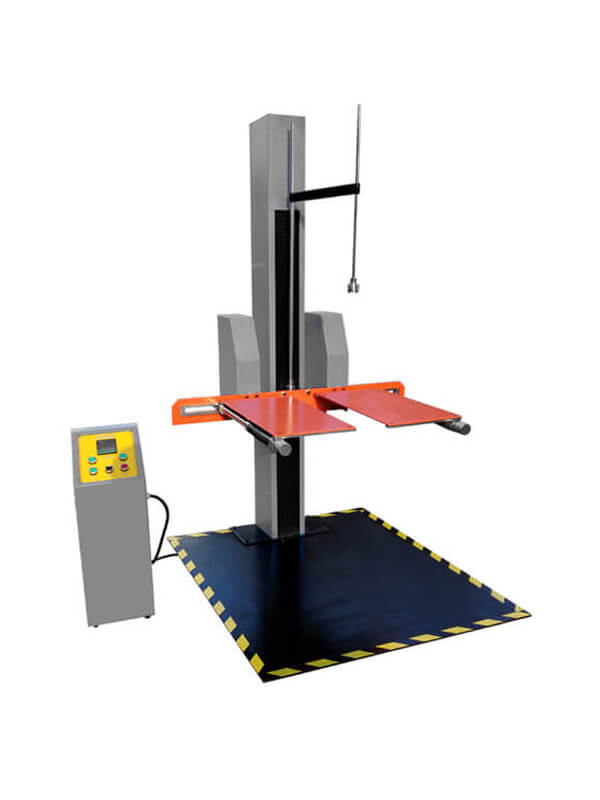

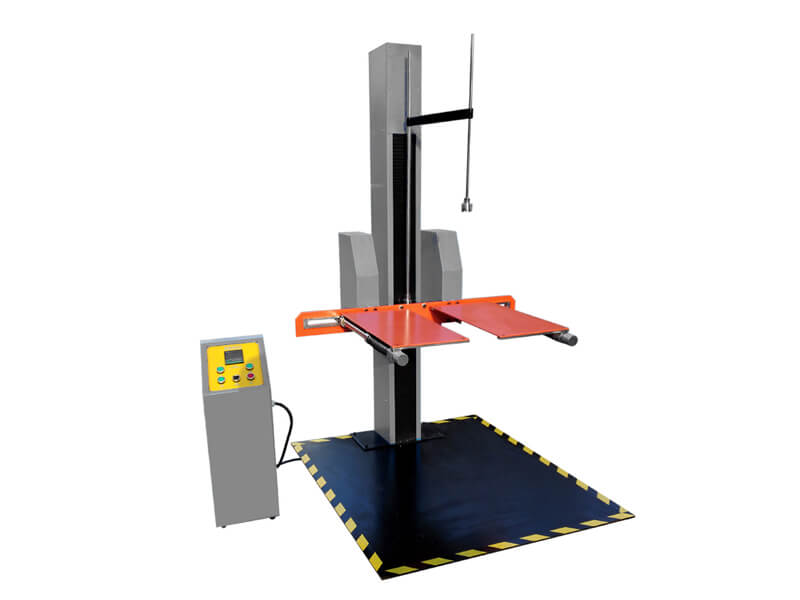

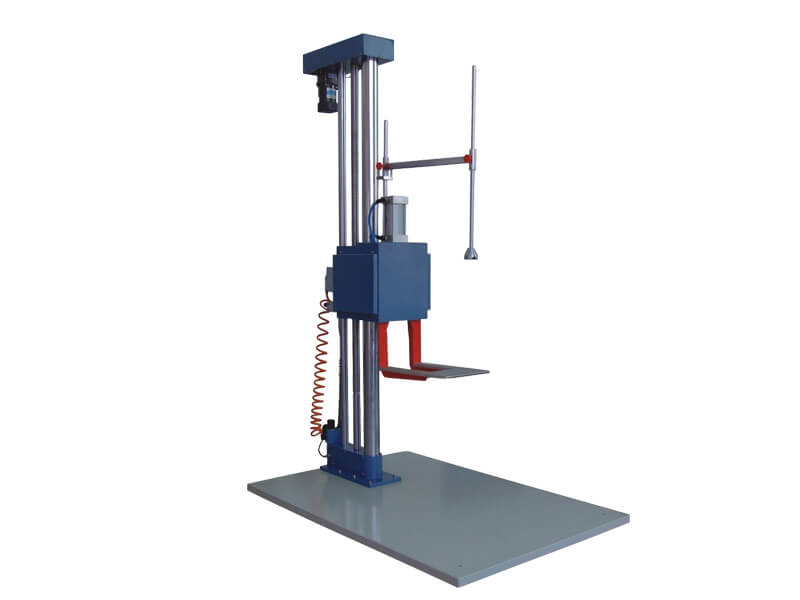

This single-wing drop test machine is an economical drop tester developed by AMADE TECH. Its structure is stable and can load up to 80 kg. It has a single-wing support arm, which is more suitable for drop tests on small-sized and regular-shaped cartons. In addition, we have other drop test machines for customers to choose from, such as the pneumatic drop test machine based on the ISTA test standard, the double-wing drop test machine designed for irregular samples, and the zero distance drop tester designed for large-size and bulky packages.

| Model | AT-D3004 |

| Drop Height Range | 300 mm ~ 1500 mm (standard)

300 mm ~ 1800 mm (optional) 300 mm ~ 2000 mm (optional) |

| Testable Max. Weight of the Specimen | 80 kg |

| Testable Max. Dimension of the Specimen | 800 × 800 × 1000 mm |

| Impact Surface Dimension | 1700 × 1200 mm |

| Impact Surface Material | Solid iron, 10 mm (horizontal flat rigid)

Concrete or wood plate |

| Drop Height Deviation | ± 10 mm or not more than 2% |

| Drop Angle | Surface, edge, sharp corner |

| Control Mode | Electric |

| Impact Panel Parallelism | < 1° |

| Machine Overall Dimension | Appr. 1700 × 1200 × 2315 mm |

| Weight | 300 kg |

| Power | AC 380V, 50Hz, 3 Phase 4 wires + earth wire or Specified |

- ISO 2248 Packaging – Transport package – Vertical impact test method by dropping

- GB/T4857-5 Packaging – Transport package – Vertical impact test method by dropping

- ASTM-D5276 Standard test method for drop test of loaded containers by free fall

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.