Free Fall Drop Test Machine for Electronic Products China Supplier

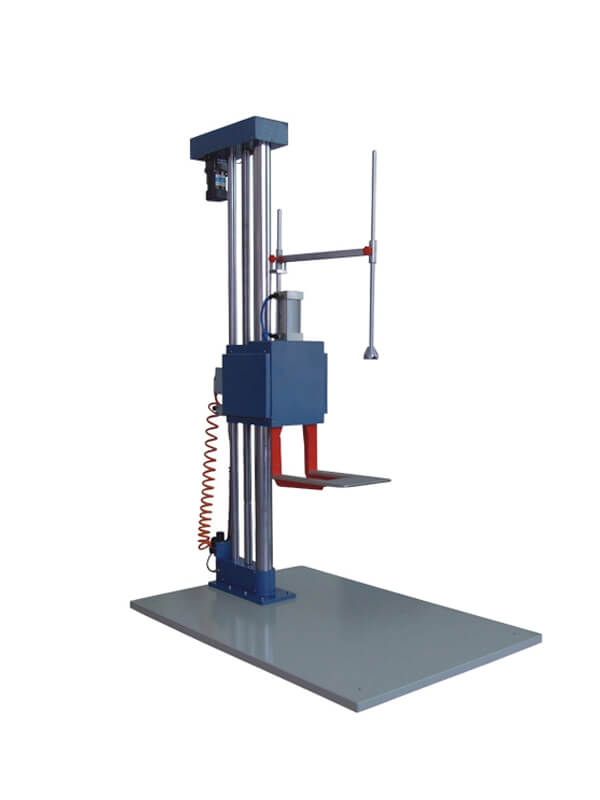

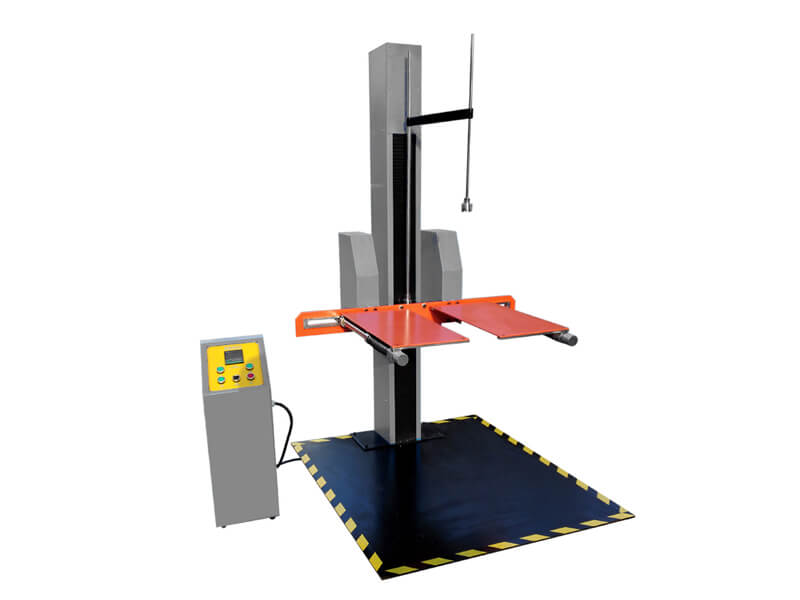

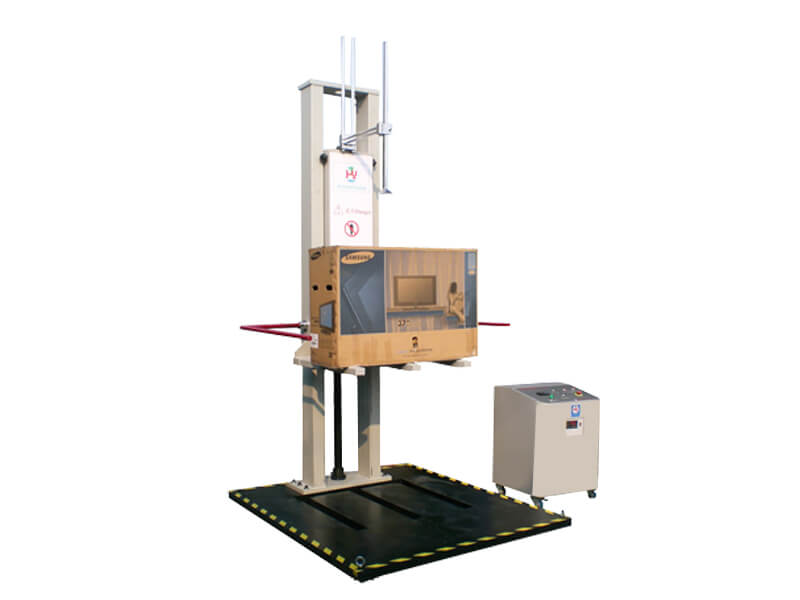

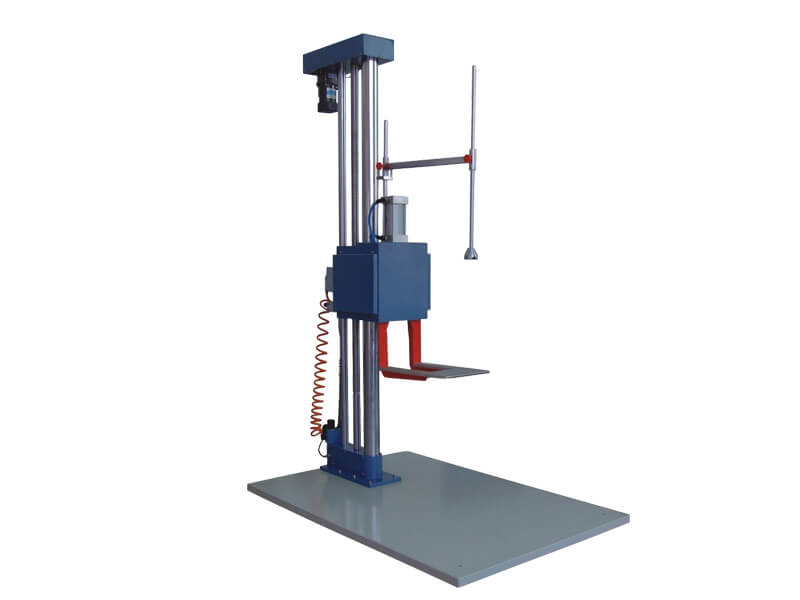

Free Fall Drop Tester is intended to simulate the accidental drop of various electronic products from different heights in a free-fall manner. The resistance of the sample to drop is judged by evaluating the degree of damage to the sample. It is a vital device to examine the ability of products to withstand unexpected shocks.

This drop test machine is designed for small and light products like cell phones and other electronic products. These products may inevitably fall on the ground and be subjected to shocks during use, so the free fall drop test is required to be conducted on them before leaving the factory. Usually, the electronic products for the free fall drop test are not protected by any packagings.

The free fall drop tester features a heigh-adjustable pneumatic grip, capable of holding the desired sample firmly in the pneumatic method. The silicone rubber is distributed on the jaws of the gripping device to prevent damaging the clamped specimen. The clamping width of the grip can be adjusted to suit as many samples as possible. You are allowed to position your sample in any postures in the clamp. The machine can achieve the free fall drop test on corners, surfaces, and edges of the sample. A height gauge is installed in the column to track the height, and the drop height can be adjusted electrically under control.

Below models are free fall drop testers with different drop heights from AMADE TECH:

| Model | AT-D3007 |

| Specimen Max. Weight | 3 kg or 5 kg |

| Drop Height | 300mm ~ 1500 mm (Standard), 2000 mm and 3000 mm available |

| Drop Height Display | Scale on the vertical shaft, minimum scale value:1 mm |

| Lifting Method | Electric lifting (A motor drives the screw moving up and down) |

| Clamp Method | Pneumatic arm |

| Pneumatic Arm Width | (3 ~ 120) mm adjustable. The wider ones available |

| Drop Gesture | Flat, Edge, Corner |

| Drop Mode | Free fall |

| Impact Floor Material | Steel plate, marble, Cement slabs, Wood board (Optional) |

| Machine Overall Dimension | W 700 × D 600 × H 1850 mm |

| Weight | 100 kg |

| Power Supply | 1 Phase, AC220 V, 50 / 60 Hz or specified by users |

| Air Supply | 0.4 Mpa ~ 0.8 Mpa |

- JIS C 0044

- IEC 60068-2-32

AT-D3007 Drop tester is used for the drop test on digital products, consumer electronics, smart phones and computers, electrical parts, small and lightweight objects.

We also provide the Rotating Drum Drop Tester and Orientation Drop Tester for handheld mobile devices and Pneumatic Drop Tester for the electronic devices with packaging.

Learn More About the Drop Test on Electronic Products

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.