Tumbling Barrel Testing Machine China Supplier

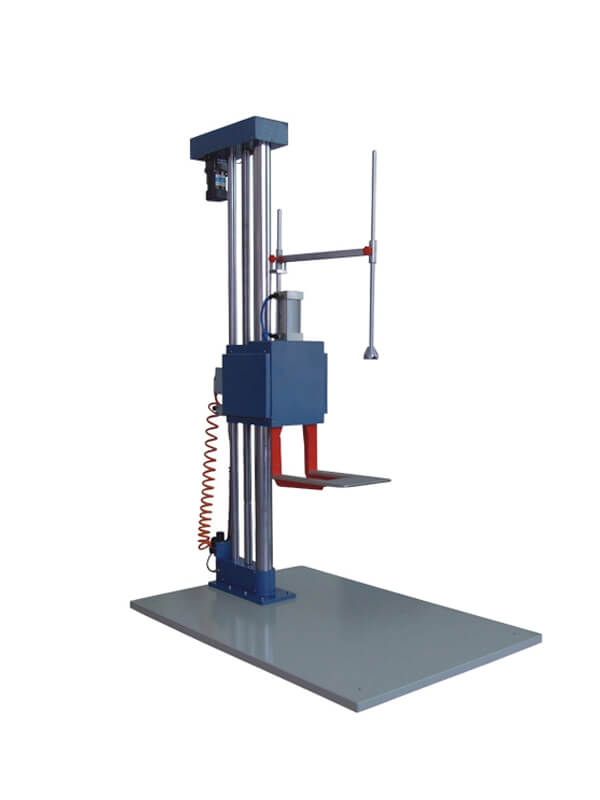

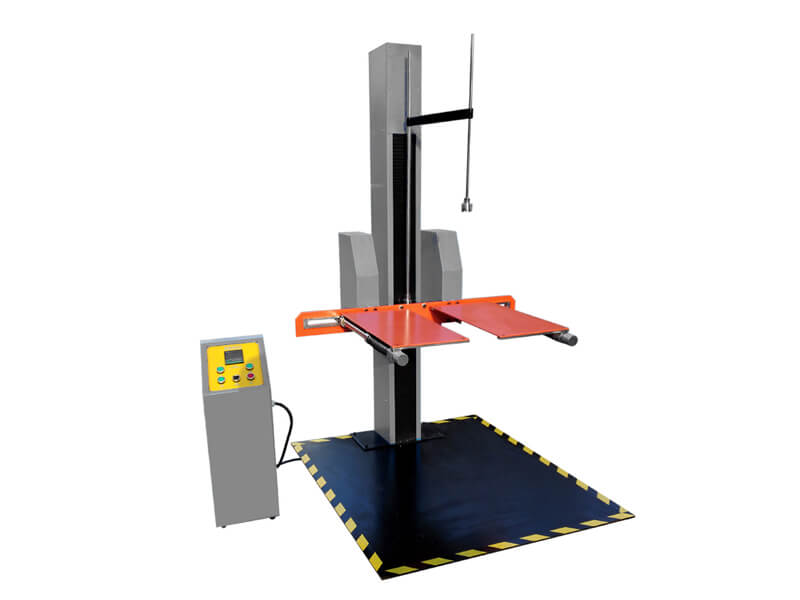

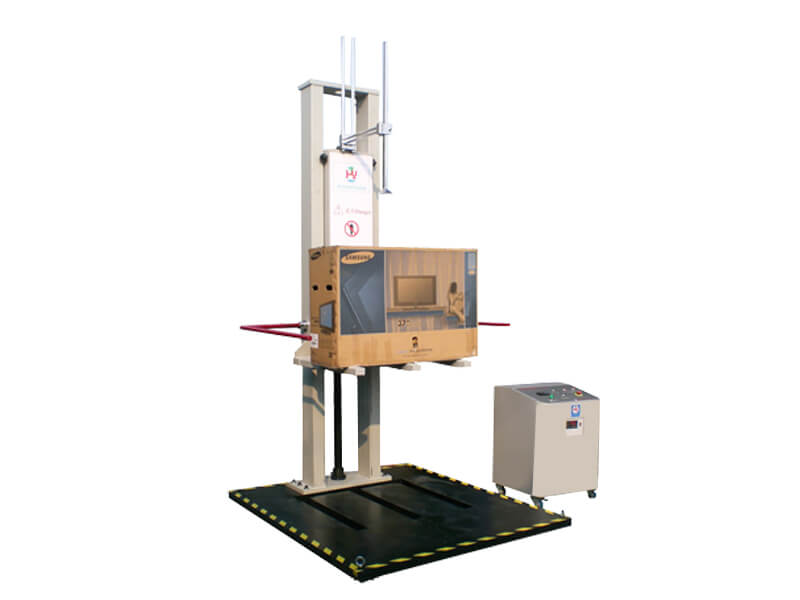

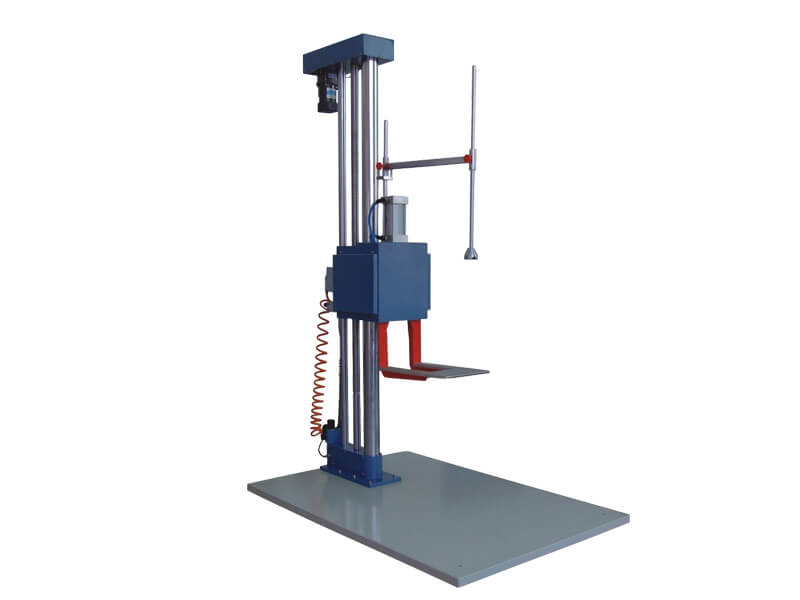

Rotating Drum Drop Tester is also called the tumbling barrel testing machine or tumbling barrel tester, which is used to determine the continuous drop resistance of various small and lightweight portable electronic products.

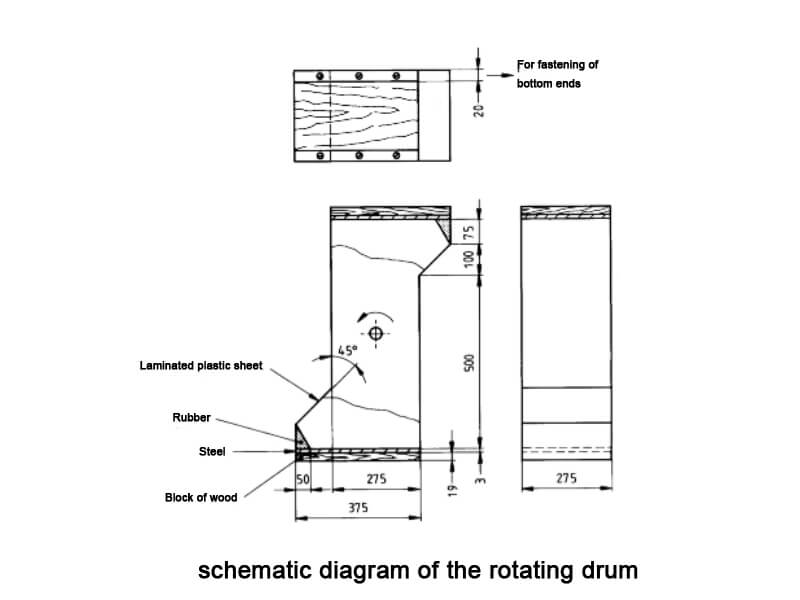

The rotating drum drop tester features a single or multiple drums having the function of rotating at a specified speed under control. The specimen inside the drum follows the movement of the barrel to tumble continuously in random free fall. It is mainly suitable for various small electronic products such as mobile phones, PDAs, electronic dictionaries, remote controls, and so on.

The control panel of the normal version is fitted with LED displays and physical keys to present the tumbling speed, number of rotations, and for parameter setup. A touch LCD is configured on advanced versions of the tumbling barrel testing machine. The test speed can be set freely from 5 to 20 times per minute. The maximum mass of the single test piece that is allowed to test is 5 kg, and the drop height can be selected from 500 mm and 1000 mm.

AMADE TECH can supply single-drum, twin-drum and customized multi-drum drop testers. In addition, we can also equip a transparent acrylic protective cover for the tumbling barrel testing machine to better ensure the safety of testing personnel.

A single sample is put into one drum. After the machine is started, the motor drives the drum to perform continuous rotation until the specified number of times. The damage caused to the sample is visually examined by the operator to evaluate its performance.

| Model | AT-D3006 |

| Specimen Load | Max. 5kg |

| Barrel Rotating Speed | 5 ~ 20rpm adjustable |

| Barrel Rotating Number | 0 ~ 9,999 times settable |

| Drop Height | 500 mm or 1000 mm or Customized |

| Barrel Quantity | Single, Double or multiple |

| Control Mode | LED intelligent control or PLC touch screen |

| Power supply | 1 Phase, AC220V 50 / 60 Hz or specified |

| The peripheral safety cover is optional | |

- IEC 60068-2-32 Environmental testing. Part 2: Tests. Test Ed: Free fall

- IEC 60884.1 Drop resistance test of electrical accessories

- IEC61058

- EN 50075 Drop resistance test of plug sockets electrical accessories

- IEC 60598-1

- VDE 0620-1

- BS 1363.1

- UL 60730

- IEC 60312

- MIL-STD-202G (Method 203C) Random drops

We also offer the Free Fall Drop Tester, Orientation Drop Tester and Pneumatic Package Drop Tester for drop testing of electronic devices:

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.