Package Drop Testing Machine China Manufacturer

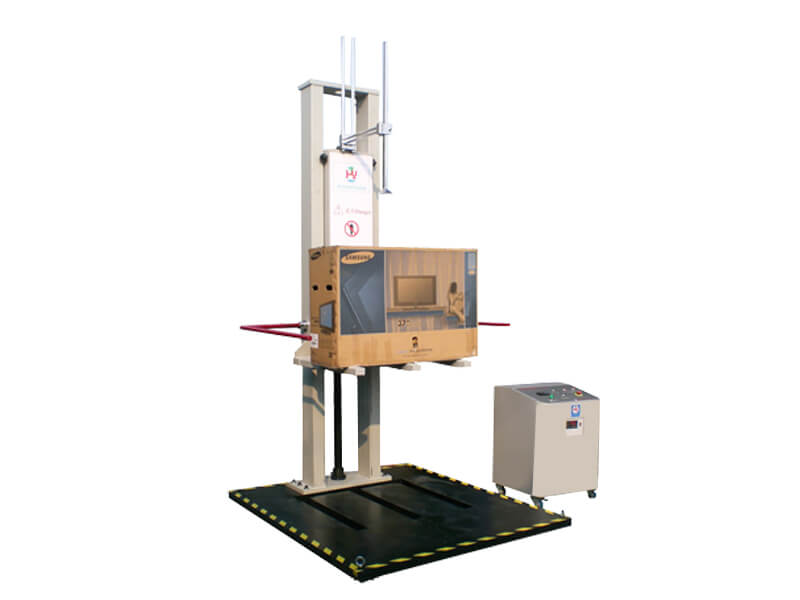

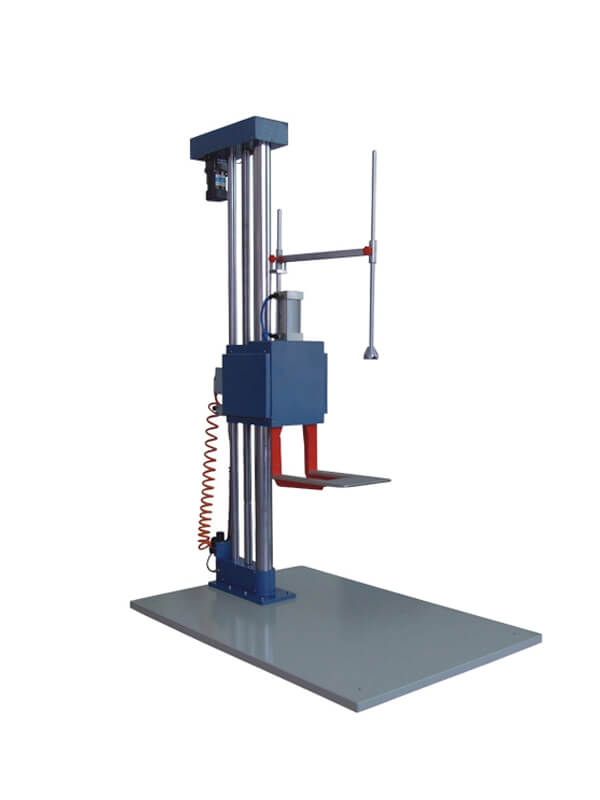

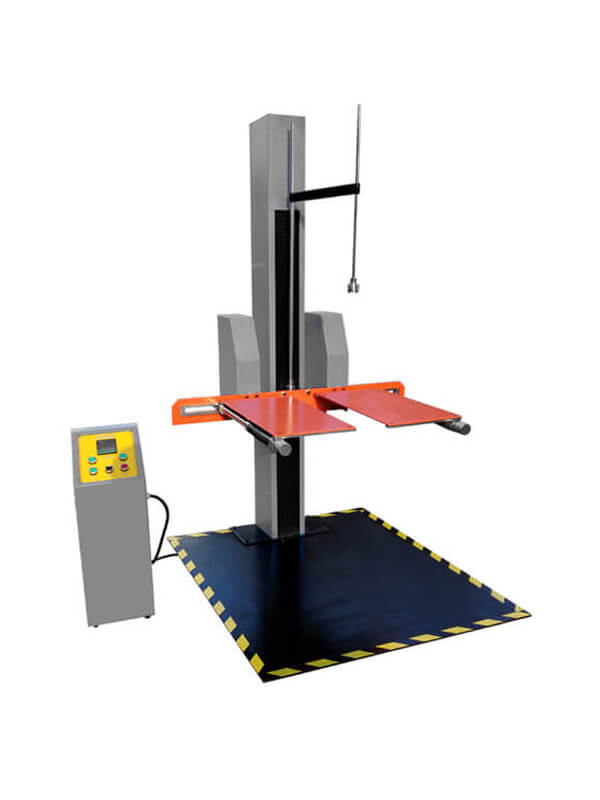

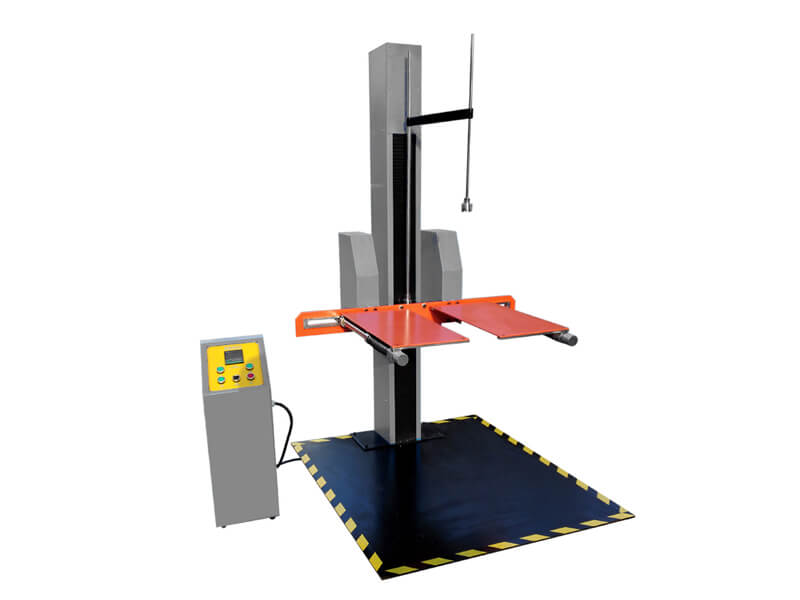

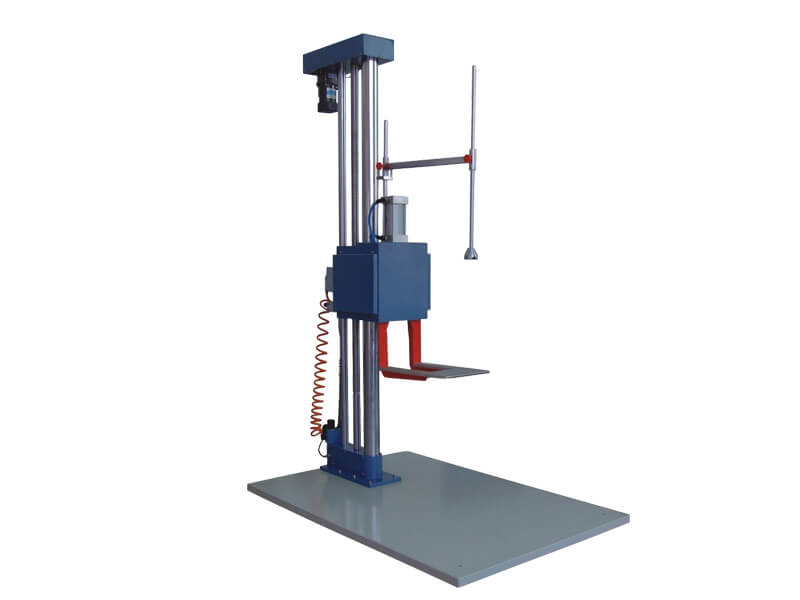

Zero Distance Drop Tester is used to simulate the free fall of the packaging carton from the specified height to evaluate the impact resistance of the package and the content inside it in the actual loading, transportation, and unloading process. And it also helps judge whether the packaging design is rational.

We call it “Zero Distance” because theoretically, it can achieve the lowest drop height of zero, thanks to its unique structure and sample release mechanism. This minimum drop height can’t be achieved by other drop test machines, such as single / double-wing drop test machines, pneumatic drop test machines, and orientation drop test machines.

AmadeTech zero-distance drop tester is mainly applicable to large-mass and large-volume packages. Generally, the vertical height from the floor during transportation and handling is relatively low for large packaged goods, so their required drop test height is also relatively low. The zero drop testing machine is ideal for testing such bulky samples.

It is equipped with an “E”-shaped “Fork” as a support arm to hold the specimen, which is capable of moving down faster than the gravity acceleration. Before the test, any one of the specimen’s faces, edges, or corners is allowed to be positioned towards the bottom plate. During the test, the fork moves downwards at a much higher speed than that of the specimen until it is flat embedded into the bottom plate. A high-efficiency shock absorber is available to reduce the impact. The sample is dropped to the bottom plate in free fall to complete a test.

We have different specifications of zero distance drop testers for you to choose from:

- AT-D3003-B

- Max. Load – 100 kg

- Drop Height – 0 ~ 1.5 m

- Max. Specimen Size – 1000 * 1000 * 1000 mm

- AT-D3003-C

- Max. Load – 200 kg

- Drop Height – 0 ~ 1.5 m

- Max. Sample Size – 470 * 1250 * 1120 mm

- AT-D3003-D

- Max. Load – 300 kg

- Drop Height – 0 ~ 1/1.5/3 m

- Max. Sample Size – 1000 * 1000 * 1000 mm

| Model | AT-D3003 |

| Max. Specimen Weight | 100 kg, 200 kg, 300 kg or customize higher capacities |

| Max. Specimen Size | 1000 mm × 1000 mm × 1000 mm or larger based on requirements |

| Drop Height | 0 ~ 1500 mm |

| Machine dimension | 1900 mm x 1700 mm x 2800 mm |

| Drop Angle | Corner / edge / face |

| Operation Mode | PLC + touch screen |

| Release Method | Pneumatic release |

| Drop Mode | Free fall |

| Lifting Method | Electric motor |

| Power Supply | 3 phase, AC 380 V ± 10% or specified |

The package sample is positioned on the “E” fork in the desired posture and automatically lifted to a given height under control. The sample falls to the metal plate after the drop button on the control cabinet is pressed. During the descending process, the fork moves downward at speed greater than the gravity acceleration separating from the specimen until the fork falls into the grooves in the bottom plate without a rebound.

- ISO 2248

- ASTM D5276

- JIS Z 0200

- JIS Z 0202

If you are looking for more different drop test machines for drop testing of small packages less than 80 kg, please check out our Pneumatic drop tester, Single-arm Drop Tester and Double-arm Drop Tester, or directly reach us to learn more.

Send an Inquiry Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.