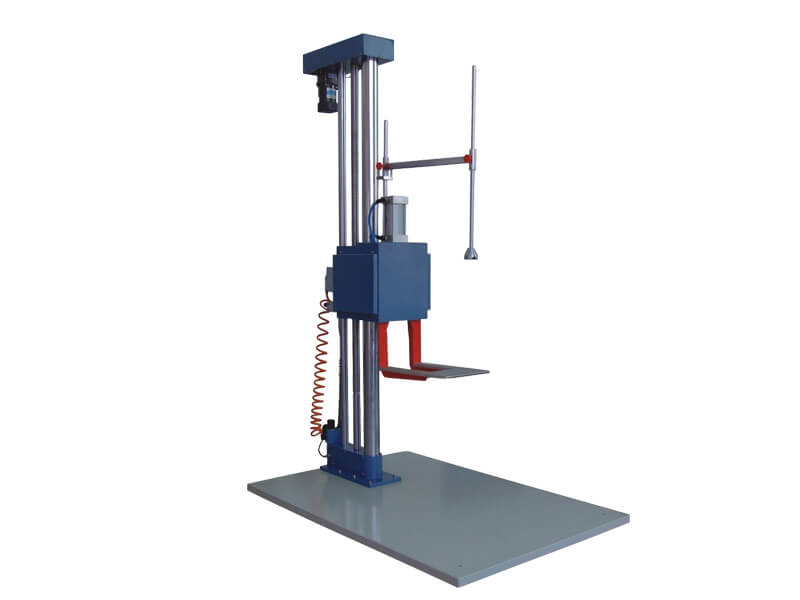

Double-wing Drop Test Machine China Manufacturer

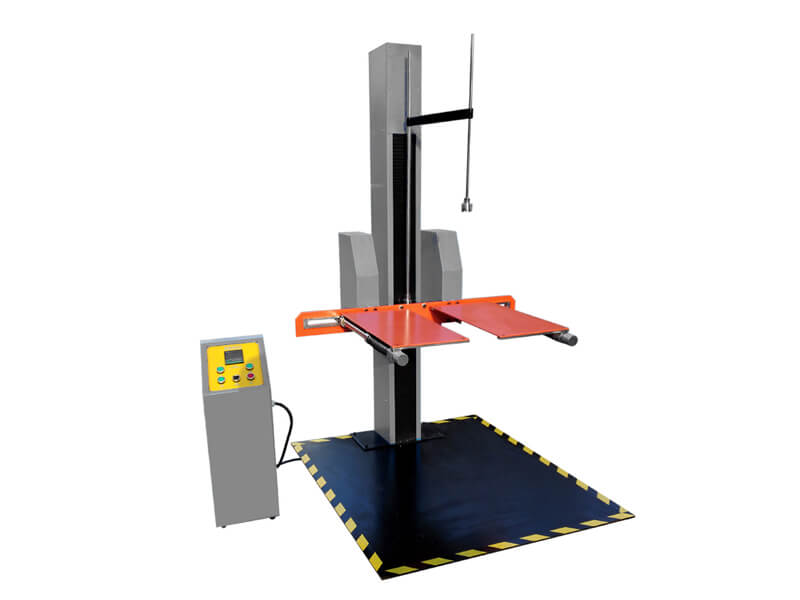

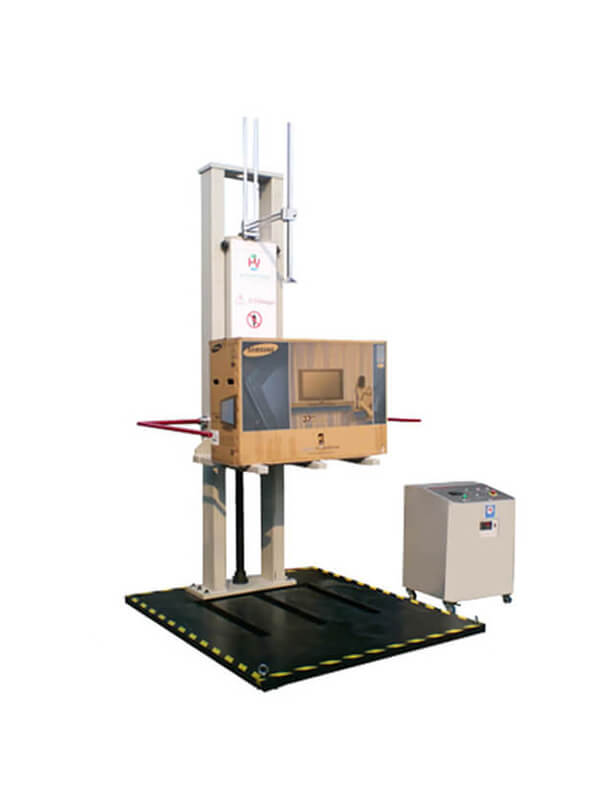

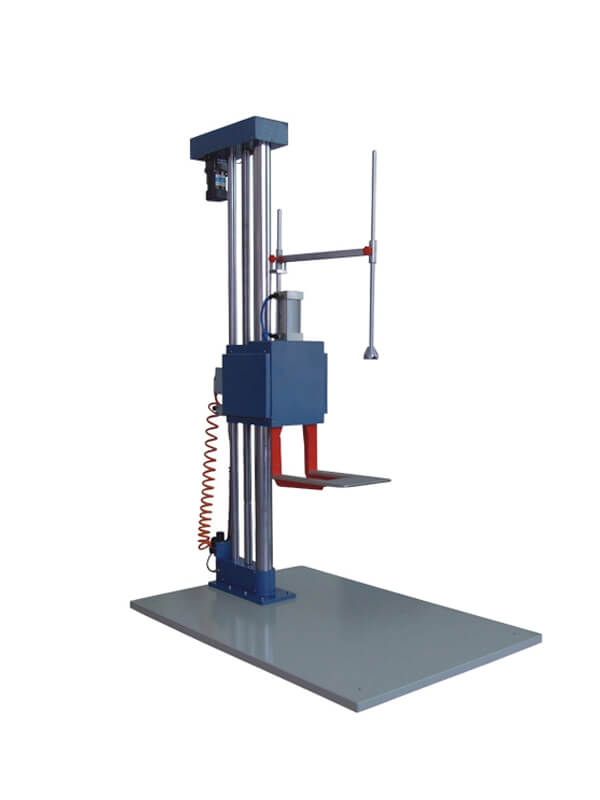

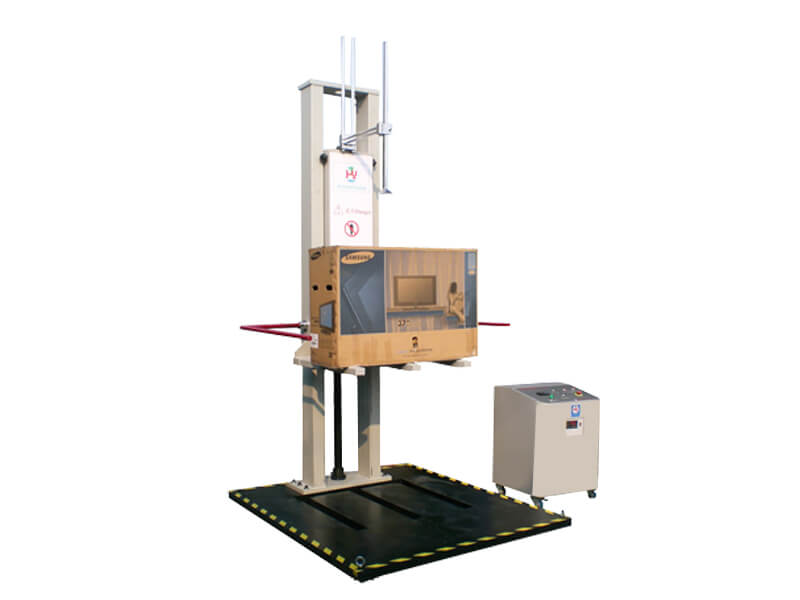

Double-Arm Drop Tester is able to simulate the scenario where a package filled with products falls onto the floor during handling, loading, or unloading to grasp the degree of damage to the outer package and the inner products, further determine the impact resistance of the package and the inner contents, and also can evaluate whether the packaging design is reasonable.

This double-wing drop test machine is an effective device to help you figure out the best packaging solution to minimize the damage and loss in transit.

It is suitable for drop tests on irregular products or packages, such as luggage cases, and It can also perform the drop test of corners, surfaces, and edges of a carton sample.

This drop test equipment can lift the test sample to a required drop height and support it in the predetermined posture until the drop occurs. Unlike the Single-arm Drop Tester with only one supporting plate, This drop tester features two arms to support the test piece. Under the remote control of the control cabinet, both arms can flip downward simultaneously to enable the sample to drop and hit the base plate in a free fall.

Due to its unique structure and operating mechanism, the lowest drop height that the double wing drop tester can accept is 40 mm, and the highest drop height is 1.5 meters. Of course, we can customize it according to your test requirements.

| Model | AT-D3005 |

| Drop Height | 400 ~ 1500 mm (customizable as per clients’ requirements) |

| Height Indication | Digital LCD |

| Single-wing Area | 300 mm × 750 mm |

| Base Plate Area | 1400 mm × 1400 mm × 10 mm |

| Max. Allowable Specimen Weight | 60 kg |

| Tested Space | 870 mm × 740 mm × 400 ~ 1600 mm |

| Drop Method | Free fall |

| Height Adjustment | Motor drive |

| Operating Language | English / Chinese |

| Horsepower | 1 HP (750 W) |

| Power | AC 380 V / 50 Hz / 2 kW or Specified |

- ISO 2248

- JIS Z0202

- GB/T4857.5

If you want to conduct a drop test on large or heavy packages from a relatively low height, a Zero Distance Drop Tester is preferable. The single-arm drop test machine and ISTA Drop tester for small cartons are also available from AMADE TECH.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.