Martindale Abrasion Machine | Martindale Abrasion Tester China Manufacturer & Supplier

Martindale Abrasion & Pilling Tester is a multipurpose textile testing machine used for determining the abrasion resistance of textile fabrics or the resistance to the formation of pills and other related surface changes on textile fabrics.

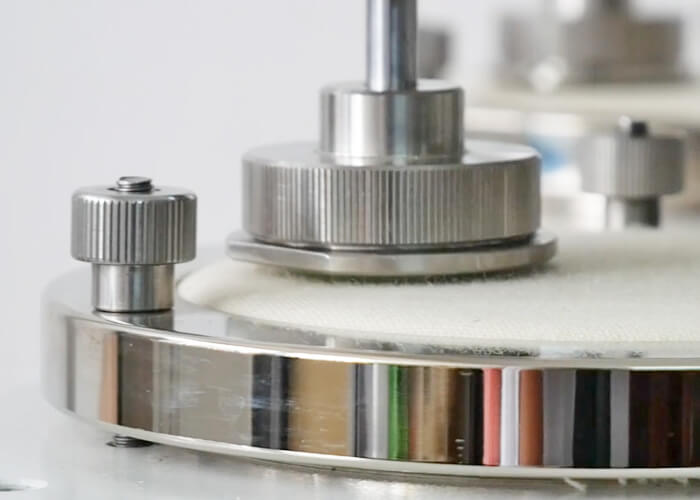

The structure of the Martindale tester consists of a metal base, clamping system, drive system, control system and display system, etc. It features a clean design, easy operation and reliable performance.

When testing the abrasion resistance of fabrics, there are 2 different testing methods and instruments. In addition to the Martindale abrasion machine, there is another machine named the Wyzenbeek abrasion tester. AMADETECH is available to provide both. Please feel free to reach us if you are interested in either.

Test Principle of Fabric Abrasion Resistance Test Using the Martindale Tester

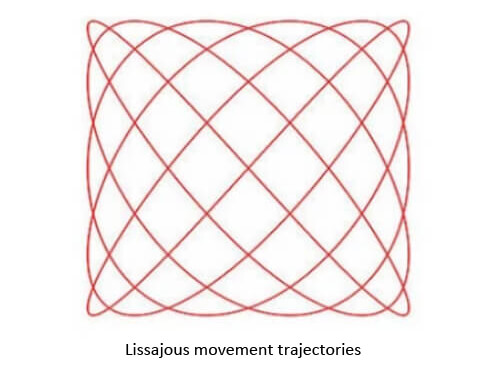

A circular test piece attached to the specimen holder is rubbed against a standard fabric in a motion drawing a Lissajous figure at a prescribed rate and under a specified pressure. Resistance to abrasion is determined from the inspection intervals to failure of the specimen using the given methods.

Test Principle of Fabric Pilling Resistance Test Using the Martindale Pilling Tester

The surface of the test specimen mounted to the sample holding device is rubbed against the face of the same mounted fabric in the form of a Lissajous figure under a specified load for a defined number of movements. Resistance to pilling, fuzzing or other surface appearance changes is evaluated by a visual comparison of the tested specimen with a standard one.

| Model | AT-T4001 |

| Work station quantity | 4/6/8/9 optional |

| Abrading table | Diameter: (121 ± 0.5) mm |

| Pressing weight mass | (2.5 ± 0.5) kg |

| Controller | PLC + LCD |

| Speed | (47.5 ± 2.5) RPM |

| Counter | 0 ~ 999,999,999 |

| Power supply | 1 phase, AC 220 V or 110V (specified) |

| For the Abrasion Test | |

| Maximum stroke of specimen holder movement | (60.5 ± 0.5) mm |

| Weight of the specimen holder & guide spindlle | (198 ± 2) g |

| Holder insert diameter | 38.1 mm |

| Load mass | (395 ± 7) g

(595 ± 7) g |

| For the Pilling Test | |

| Maximum stroke of specimen holder movement | (24 ± 0.5) mm |

| Weight of the specimen holder & guide spindlle | (155 ± 1) g |

| Specimen holder diameter | Φ90 mm |

| Load mass | (260 ± 1) g |

|

|

- ASTM D4966

- ASTM D4970

- BS EN 388

- BS EN 13770

- BS EN ISO 17076

- ISO 12945-1

- ISO 12945-2

- ISO 12947

- JIS L1096

- M&S P17

- M&S P18C

- M&S P19

- P19A

- P19C

- SATRA TM31

- PV 3928, etc.

Martindale Abrasion Testing Machine Features

- It is made of precision stainless steel to ensure rigidity and durability.

- A flexible number of workstations, including 4 / 6 / 8 / 9, are available for selection.

- Two types of Lissajous trajectories (strokes of 24 mm & 60.5 mm) are available, enabling measurements for abrasion & pilling resistance.

- The touch screen is adopted, and the operation interface is simple and easy to understand.

- Two counting methods are available: counting up and counting down.

- Each test station can be counted separately.

- Driven by variable frequency motor, to allow the instrument to run smoothly.

- The test speed is adjustable, which can meet different test standards.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.