Environmental Test Chamber | Climatic Chamber China Manufacturer

Programmable Temperature Humidity Test Chamber is also referred to as Constant Temperature Humidity Chamber or Environmental Test Chamber.

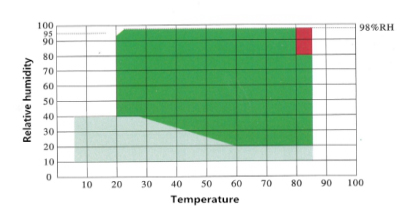

This chamber can simulate the temperature & humidity ranging from extremely low values at -70℃ & 20% R.H to exceeding high values at 150℃ & 98% R.H to determine the adaptability of various materials or finished products to heat, cold, dry and wet, and It is also used to evaluate the changes in the performance of test pieces to be used, stored or transported in a variety of temperature and humidity conditions.

The heating system, refrigeration system, humidification system and dehumidification system are integrated into this environmental testing equipment, allowing the one machine to reproduce various conditions including high temperature, low temperature, high humidity, low humidity under the dynamic or steady-state control and monitoring.

Moreover, the different stages of climate can be programmed in advance in the form of various combinations in the loop, which brings a higher similarity to the natural environments. After the specimen is tested by this programmable temperature chamber for a relatively short time, It helps people pass through space-time to see the changes in the specimen’s appearance and property ahead of time, which will occur in one year, two even five years.

INQUIRE

Applications

The environmental test chamber is widely applicable to electronics, plastics, rubbers, electronic products, electric appliances, instruments, automobile parts, metals, construction materials, spacecraft parts, etc.

In order to meet different testing requirements, various jigs can be built inside the chamber to achieve applications to footwear, leather and other specimens. For example, Hydrolysis Test Chamber, Safety Shoe Cold Insulation Tester, Low Temperature Bally & Ross Leather Flexing Tester are derived from this environmental test chamber.

Test Standards

- IEC60068-2-1 Environmental testing Part 2-1: Test: Cold

- IEC60068-2-2 Environmental testing Part 2-2: Test: Dry heat

- IEC60068-2-78 Environmental testing Part 2-78: Test: Damp heat steady state

- IEC60068-2-30 Environmental testing Part 2-30: Test: Damp heat cyclic (12h + 12h cycle)

- MIL-STD-810D Low temperature, high temperature, Dump heat test

- MIL-STD.202F High temperature test

Main Technical Parameters

| Model | AT-C1001 |

| Temperature Range | 0℃ ~ 150℃, -20℃ ~ 150℃, -40℃ ~ 150℃, -70℃ ~ 150℃ (optional) |

| Temperature Resolution | 0.01℃ |

| Temperature Fluctuation | ± 0.5℃ |

| Temperature Uniformity | ± 2℃ |

| Temperature Accuracy | ± 0.1℃ |

| Heating Rate | Average 3℃ / min, Nonlinear without load |

| Cooling Rate | Average 1℃ / min, Nonlinear without load |

| Humidity Range | 20 % R.H. ~ 98 % R.H. |

| Humidity Fluctuation | ± 2.5 % R.H. |

| Humidity Uniformity | Humidity > 75 % R.H.: ≤ ± 2 % R.H. / 3 % R.H.

Humidity < 75 % R.H.: ≤ ± 5 % RH |

| Humidity Resolution | ± 0.1 % R.H |

| Temperature Humidity Comparison Chart |  |

| Inner Chamber Dimension (W x H x D) | 400 x 500 x 400 mm (80 L), 500 x 600 x 500 mm (150 L)

500 x 750 x 60mm (225 L), 600 x 850 x 800 mm (408 L) 1000 x 1000 x 800 mm (800 L), 1000 x 1000 x 1000 mm (1000 L) |

| Main Materials | The inner chamber is made of SUS304 first-class stainless steel, and the outer chamber is fabricated from cold-rolled steel plates and treated with high-grade paint |

| Insulation Layer Between Inner and Outer Chamber | Polyurethane foam and glass wool for better insulation performance |

| Refrigeration System | TECUMSEH or Bitzer Fully enclosed or semi-enclosed compressor, using environmentally friendly refrigerant

The cooling and heating cycle system and key electrical components of the refrigeration unit adopt world-renowned brands |

| Temperature and Humidity Control System | World famous brand TEMI or OYO |

Temperature and Humidity Test Chamber Features

- Precision stainless steels are used for the formation of integral frame, functional area and external appearance.

- Highly intensive and environmentally friendly PU polyurethane foams featuring the same fire-resistant grade as Germany Bayer are used as insulation material to ensure that the testing equipment owns the excellent ability of resistance to heat and cold.

- A viewing window with the sweat-resistant function provides a clear view at any time during the test.

- Equipped with an intelligent and programmable temperature and humidity adjustment device and a 7-inch touch-screen LCD interface for real-time monitoring and control throughout the test.

- Fitted with an unique humidification dehumidification system with a precision PT100 temperature humidity sensor for accurate control.

- Configured with a balanced temperature & humidity system to achieve stable and precise control.

- It can be preset to start the machine and owns functions of power-off memory, alarm text prompt, real-time monitoring of temperature and humidity.

- This chamber has a strong controller programming capacity: 120 groups of 1200 segments, PID automatic calculation + SSR/SCR forward and reverse synchronous output.

- A titanium alloy heater with longer service life is used, and the unique circulating air duct design makes the temperature inside the chamber more uniform.

- Equipped with various safety protection systems embedded in different modules, including heating and humidifying protection system, refrigeration protection system, water supply protection system, power protection system, etc.

Features of Refrigeration System

- As the heart of the refrigeration system, we use top international brands like TECUMSEH fully enclosed piston-type compressor to ensure rapid and accurate heating and cooling, and trouble-free use for a long time.

- The refrigerant is fluoride-free, eco-friendly HFC R404A or R23.

- “Emerson” Oil separator is used to separate high-pressure oil from the compressor.

- It is configured with an air-cooled high-efficiency condenser.

- Refrigerating evaporator is an efficient multi-segment finned evaporator with the hydrophilic membrane (fin thickened type).

Functions of Programmable Temperature & Humidity Test Chamber

- Used to conduct the tests conditioning temperature and humidity as specified for a given period to determine the heat resistance, cold resistance, dry resistance and moisture resistance of various test pieces to evaluate the reliability and durability.

- Used to carry out the tests based on alternating conditions of different temperature values and humidity values in terms of the preset program. The temperature rise is easy to practice via electrical heating, but the temperature drop is more complicated, whose working principle is the phase changes of the refrigerant by means of a powerful compressor inside the machine.

- Used to perform the high and low-temperature tests. When shutting down the humidification function, It will become a precision high-low temperature test chamber to assess the resistance of the specimen to extreme high and low temperatures. Both the constant high-temperature test as high as 150℃ and the constant low-temperature test as low as -70℃ can be completed using this environmental chamber.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.