IEC 60529 IPX8 Continuous Submersion Test Setup Supplier

IPX8 Immersion Pressure Test Device is a waterproof tester with a tank that can simulate different water pressures acting on the test piece at a depth from several meters to tens of meters. Before testing, the appropriate amount of water needs to be added to the tank, then the sample needs to be completely immersed in the water, and then the lid of the tank needs to be capped and sealed. The water immersion test equipment has an efficient pressurization system to continuously pressurize the sealed tank until it reaches the preset value. After reaching the specified pressure value, the pressure inside the tank can be maintained for the specified time. The sample passes the test if the ingress of water in quantities causing harmful effects never happens.

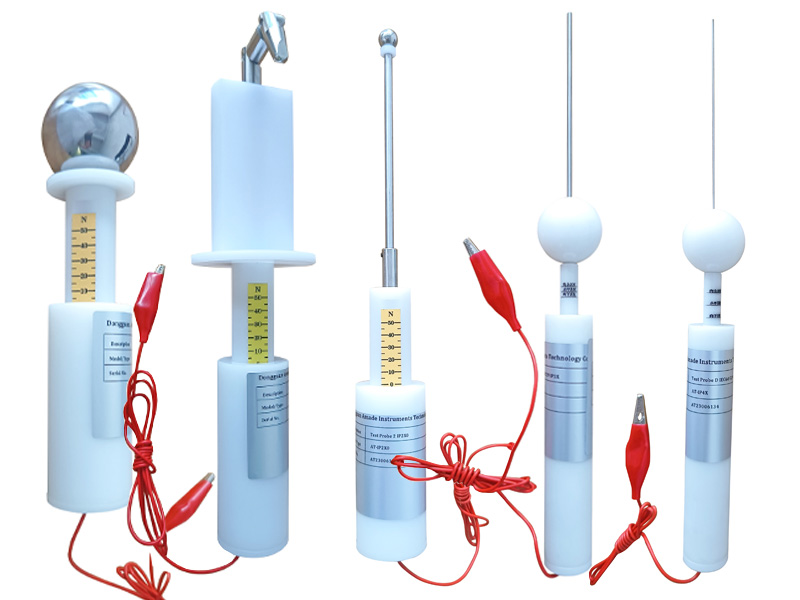

IPX8 test conditions require the sample to be continuously immersed in water at a depth more severe than that stipulated in IPX7. This depth is not a fixed value varying from a few meters to tens of meters. In the laboratory, it is almost impossible for us to place samples to the actual desired water depth for testing due to objective conditions. The only way to achieve it is to figure out the pressure an object shall be subjected to at a desired depth of water and then place the sample in a device that can simulate the water pressure corresponding to the desired depth to complete the test. The IPX8 immersion pressure test device from AmadeTech is designed to meet this test requirement.

AmadeTech IPX8 water immersion tester’s tank body adopts thickened 304 stainless steel to ensure adequate strength to withstand rated pressures. The dimension of the tank can be tailored to specimen specifications. For those cylindrical tanks with large diameter and height that are difficult to open and close manually, we specially equip both sides of the tank with a pair of pneumatic lifting devices to achieve smooth and automatic opening and closing the lid under control, so as to enhance the ease of operation and eliminate operational risk.

The lid and the tank opening are sealed with a silicone sealing ring with excellent sealing performance, coupled with 8 bolts to fasten both firmly, which are evenly locked to make them fit tightly, resulting in the remarkable pressure retention performance of the entire tank. For some models, we add a viewing window on the lid for you to observe the condition of the specimen during the test.

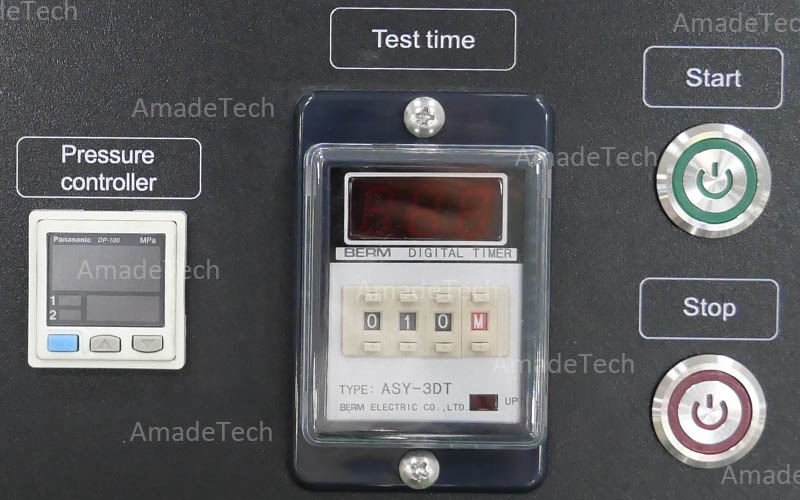

A pressure sensor is located inside the equipment, working closely with a set of pressure measuring and control systems. After you set the desired pressure as required, the machine will run to pressurize the tank until it reaches the set value and can automatically control and maintain the pressure for a specified time. The sample is subjected to a preset pressure in water during the test. If the sealing performance of the sample is not good, the water will penetrate the outer casing and enter the sample interior under the action of high pressure. The real-time pressure value and elapsed test time are displayed on the digital screens on the control panel.

Control panel

Exhaust valve

Safety valve

Each device is fitted with a manual exhaust valve and an automatic pressure relief valve (safety valve) on the lid. The manual exhaust valve is used to assist in accelerating pressure relief after the pressure holding stage. During the test, if the rated pressure is exceeded, the relief valve will automatically release the excess pressure to guarantee the absolute safety of the test.

In addition to stainless steel tanks, AmadeTech can also provide IPX8 water immersion test equipment with glass tanks. When you submerge the sample in water for testing, if the sample is defective, bubbles will appear continuously in the water. Compared with stainless steel, its biggest advantage is that it allows you to intuitively see the specific location of the leak point of the unqualified sample, which can help you easily grasp its waterproof weak point and improve the design of the product.

The machine supports positive pressure mode and negative pressure mode for detection. You can input the desired pressure value to meet the needs of the test. The volume of the tank and the maximum positive and negative pressure can be customized according to the needs. Generally, the pressure at a water depth of 10 to 50 meters can be simulated.

Please get in touch with AmadeTech specifying your testing requirements on the sample size, required water depth (pressure), and test mode. We will get back to you with an appropriate solution to fit your testing.

If you are interested in more IP Testing Equipment, please feel free to Click HERE to learn more.

Conforming Standards

- IEC 60529

- ISO 20653

- DIN 40050-9, etc.

Technical Parameters

Model | AT-C1005E-300-30 | AT-C1005E-500-30 | AT-C1005E-500-50 | AT-C1005EI-600-30 | AT-C1005EI-600-50 | AT-C1005EA-350-10 | AT-C1005EA-350-50 | AT-C1005EA-500-10 | AT-C1005EA-600-10 |

Interior dimensions | (Dia.) 300 x (H) 300 mm | (Dia.) 500 x (H) 500 mm | (Dia.) 500 x (H) 500 mm | (Dia.) 600 x (H) 1200 mm | (Dia.) 600 x (H) 1200 mm | (Dia.) 350 x (H) 400 mm | (Dia.) 350 x (H) 400 mm | (Dia.) 500 x (H) 500 mm | (Dia.) 600 x (H) 1200 mm |

Overall dimensions | (W) 470 x (D) 580 x (H) 910 mm | (W) 600 x (D) 800 x (H) 1050 mm | (W) 600 x (D) 800 x (H) 1050 mm | (W) 780 x (D) 850 x (H) 1750 mm | (W) 780 x (D) 850 x (H) 1750 mm | (W) 800 x (D) 550 x (H) 1000 mm | (W) 800 x (D) 550 x (H) 1000 mm | (W) 880 x (D) 650 x (H) 1180 mm | (W) 1000 x (D) 800 x (H) 1550 mm |

Pressure adjustment range | 0 ~ 0.3 MPa | 0 ~ 0.3 MPa | 0 ~ 0.5 MPa | 0 ~ 0.3 MPa | 0 ~ 0.5 MPa | Negative pressure -0.05 ~ 0MPa / Positive pressure 0.01 ~ 0.1MPa | Negative pressure -0.05 ~ 0MPa / Positive pressure 0.01 ~ 0.5MPa | Negative pressure -0.05 ~ 0MPa / Positive pressure 0.01 ~ 0.1MPa | Negative pressure -0.05 ~ 0MPa / Positive pressure 0.01 ~ 0.1MPa |

Simulated water depth range | 0 ~ 30 meters | 0 ~ 30 meters | 0 ~ 50 meters | 0 ~ 30 meters | 0 ~ 50 meters | 0 ~ 10 meters | 0 ~ 50 meters | 0 ~ 10 meters | 0 ~ 10 meters |

Applicable IP rating tests | IPX8 | IPX8 | IPX8 | IPX7 & IPX8 | IPX7 & IPX8 | IPX8 | IPX8 | IPX8 | IPX7 & IPX8 |

Tank materials | 3 mm thick 304 stainless steel (20 mm thick stainless steel flange) | 10 mm thick transparent acrylic (20 mm thick stainless steel flange) | 20 mm thick transparent acrylic (25 mm thick stainless steel flange) | 10 mm thick transparent acrylic (20 mm thick stainless steel flange) | 10 mm thick transparent acrylic (20 mm thick stainless steel flange) | ||||

Pressure sensor accuracy | 0.001 MPa | ||||||||

Pressure sensor deviation | ± 0.002 MPa | ||||||||

Compressed air pressure required | 0.6 ~ 0.8 Mpa | ||||||||

Protection devices | Pressure safety vlave and leakage switch | ||||||||

AmadeTech IPX8 Immersion Pressure Test Device Features

- Mainly made of highly rugged 304 stainless steel.

- The tank dimensions are customizable according to the sample size.

- The maximum test depth can be customized.

- Fitted with a set of powerful pressurizing and maintaining system.

- Supports presetting a target pressure and holding time.

- The system automatically relieves pressure after the test time is reached.

- A pair of air cylinders can be added to assist in opening and closing the lid.

- Equipped with safety valve to guarantee absolute safety.

- It is easy for users to operate.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amade Tech sales engineers will respond within one working day.