Lithium-ion Battery Safety Test Chamber China Supplier & Manufacturer

Lithium-ion battery explosion-proof test chamber is mainly used for overcharge, and over-discharge (forced discharge) tests on lithium-ion cells, lithium-ion battery modules, or battery packs. It can effectively resist the pressure generated by the explosion of the failed cells/batteries during the test.

At the same time, it can reduce and avoid the adverse influence of the high temperature after the burn of a single battery on other testing cells or batteries.

The battery explosion-proof test chamber is widely used in battery research and development, quality inspection, and safety performance certification.

The inner and outer materials of the explosion-proof chamber are solid steel plates with enough thickness and strength to protect surrounding people or equipment from harm in the event of battery fire or explosion.

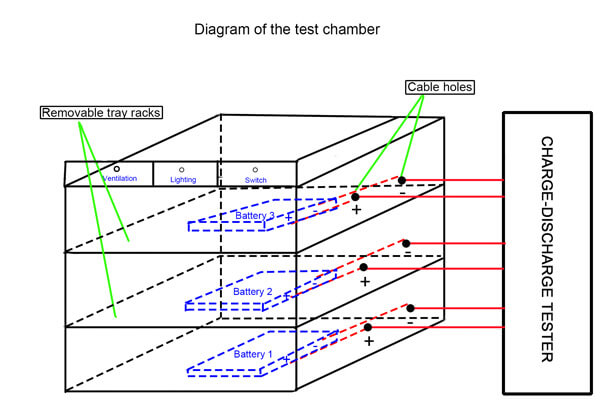

The explosion-proof chamber can be a single chamber and multiple cells that are customized, capable of accommodating multiple single cells or batteries for overcharge and over-discharge tests simultaneously.

Each cell of our standard lithium-ion battery explosion-proof test chamber is configured with the wire hole, exhaust fan, pressure relief opening, explosion-proof door lock, and explosion-proof chain.

You are also available in selecting and configuring apparatuses for gas detection, smoke detection, video surveillance, or fire extinguishing according to the hazard level.

Please click HERE if you are interested in learning more lithium-ion battery test equipment from AMADE TECH.

Main Technical Parameters

| Model | AT-L5003 |

| Standard Dimension for the Inner Chamber | 500 mm × 500 mm × 500 mm (Supports customization for other sizes) |

| Standard configurations included |

|

| Optional Safety Accessories |

|

Explosion-proof Battery Test Chambers AMADE TECH Provides

AMADE TECH is able to supply but not limited to the following explosion-proof battery test chambers.

Both standard and custom models are available.

Please get in touch with us and send your requirements for acquiring free quotation.

Single-cell explosion-proof battery test chamber

Vertical 2-in-1 explosion-proof battery test chamber

Explosion-proof battery test chamber for battery pack

2-in-1 explosion-proof test chamber for battery packs

Explosion-proof battery test chamber with fire extinguishers

8-in-1 explosion-proof battery test chamber

30-in-1 explosion-proof battery test chamber

Applications of Explosion-proof Battery Test Chambers

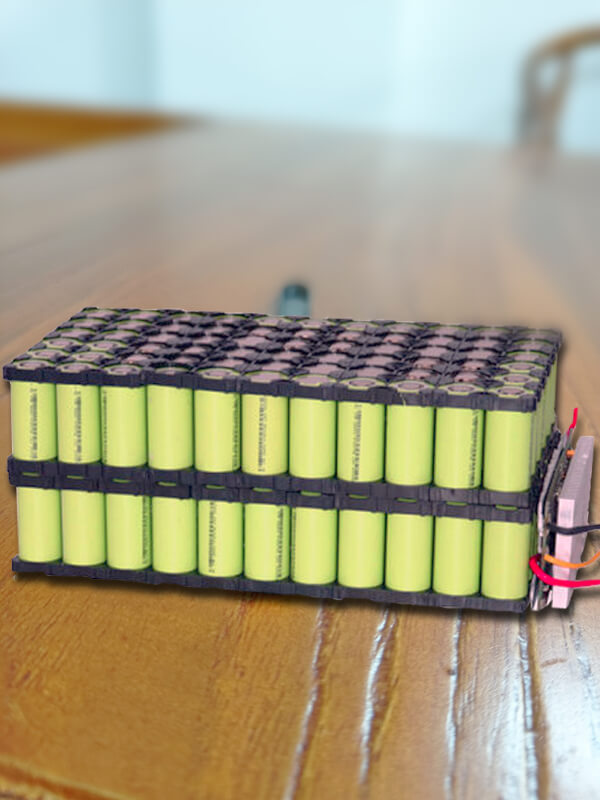

The explosion-proof battery test chambers produced by AMADE TECH can be applied to various types of batteries for overcharge and over-discharge tests, such as single cells (cylindrical, square, etc.), battery modules, and battery packs.

18650 cylindrical cells

Prismatic lithium-ion batteries

Polymer Li-Ion batteries

Lithium-ion battery module

Safety Features of Explosion-proof Battery Test Chambers

Door Lock

- Perfectly integrated into the explosion-proof test chamber.

- The lever principle is adopted to make the opening and closing of the door easier.

- Push the handle clockwise to open and continue to turn the handle until the hook slides out of the seat to open the door.

Explosion-proof Chain

- Suppose the pressure generated by the explosion of the battery in the chamber bursts open the door. In that case, the chain on the door frame can allow the door to open partially, which plays the role of secondary buffering and protection.

- Made of precision steel to guarantee enough structural strength for resisting impact force.

- It can be conveniently connected and removed by buckling the ring at the end of the chain.

Pressure Relief Port

- We specially designed a pressure relief port allowing the explosion-proof chamber to buffer the shock wave generated at the moment of the explosion to minimize the impact of pressure on equipment.

- Due to the different pressures generated by the explosion of different batteries, we will also design different sizes of pressure relief ports according to different situations.

Cable Hole

- A round hole with a diameter of 50 mm or a diameter of 100 mm is available on the left or right side of the explosion-proof chamber to facilitate the passage of various test cables during the test.

- It helps you in monitoring and recordding real-time parameters such as battery temperature, battery voltage, and AC impedance.

Exhaust Fan

- A circular exhaust fan is at the rear of the explosion-proof chamber.

- During the battery overcharge or over-discharge test, the leaked gas can be discharged from the cabinet through the exhaust fan to reduce the flammable gas in the chamber.

- The exhaust fan also extracts the smoke generated after the battery catches fire or explodes.

Observation Window

- The door is equipped with a transparent glass for better observation on samples during the test.

- Made of tempered glass to ensure the enough strength to withstand explosion.

- Coupled with wire meshes to better protect surrounding people and objects.

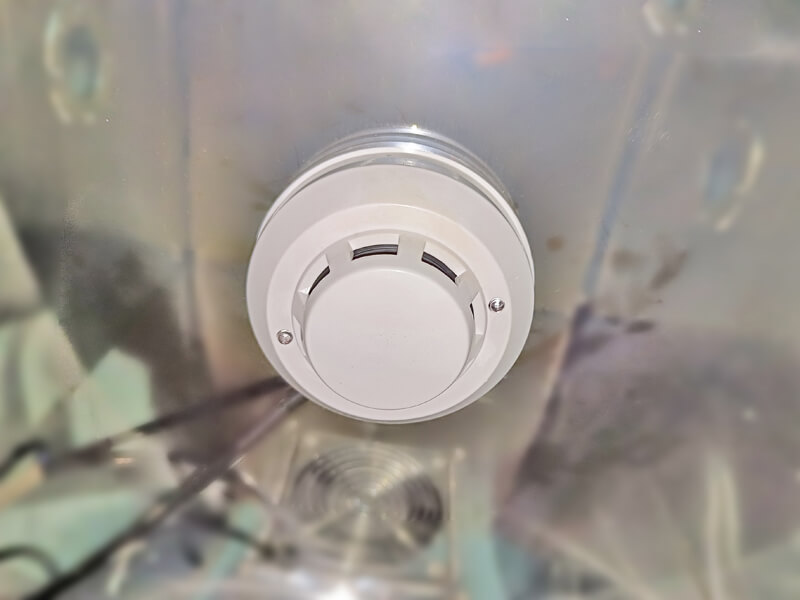

Smoke Detector

- Capable of detecting smoke inside the chamber.

- This alarm indicates that the battery under test is thermal runaway and likely to burst into flames.

- Be ready to put out the fire once it rings.

Gas Detector

- Capable of detecting leaked gases such as H2,CO, C2H4, etc. from the batteries.

- The alarm indicates the possibility of fire or explosion.

Fire extinguishing device

- Fitted with a CO2 dry powder extinguisher to suppress flames.

- Coupled with water spraying apparatus to continuously cool the failed batteries.

Video Monitoring Apparatus

- The chamber is equipped with a high-definition camera to ensure a clear picture.

- The test process can be remotely monitored to ensure personnel safety.

FAQ on Explosion-proof Battery Test Chambers

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.