IPX1/2 Rain Test Chamber China Supplier & Manufacturer

IPX1/2 Drip Test Equipment is used to simulate vertically falling water drops over the horizontal enclosure or the enclosure tilted up to 15° to determine its basic waterproof performance.

The most commonly used equipment is the box-type rain test chamber. It features a drop box of custom dimensions at the ceiling of the inner chamber. There are plenty of needles distributed in a grid pattern with a spacing of 20 mm from each other at the bottom of the drip box. The needles generate a uniform flow of water drops mimicking raindrops over the whole area of the specimen. To prevent injury when mounting and removing specimens, we add a protective mesh under the needles.

During the test, water droplets fall from the drip box onto the specimen and then flows to the water tank below the chamber. With the help of the circulation motor, the water in the lower water tank is pumped to the upper drip box continuously, realizing the recycling of water throughout the test. Moreover, the upper tank supports pneumatic drainage to discharge the remaining water after a series of test runs, which helps reduce scale formation in the drop box and extend the device lifetime.

Dripping needles

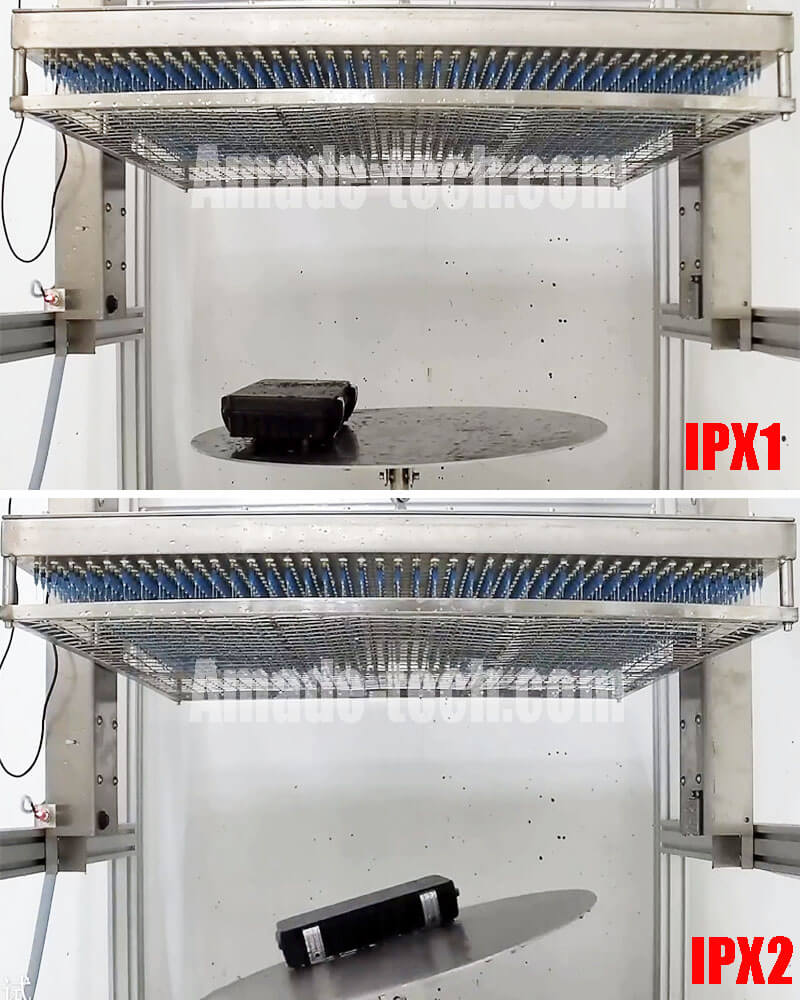

AmadeTech drip test equipment is equipped with a circular turntable made of 304 stainless steel. The specimen can be attached to it at the specified eccentricity to rotate forward and reverse at a specified speed. The turntable is in the horizontal position when conducting the IPX1 water drip test. You are required to adjust the turntable by 15° on either side of the vertical before performing the IPX2 test (Please refer to the picture on the right). The turntable’s height is adjustable to allow the distance between the needles and the specimen’s upper surface to achieve a maximum of 200 cm.

We configure the machine with a PLC and a 7″ touch screen. You only need to select the desired waterproof rating and set the necessary parameters by tapping the machine screen prior to the test. After launching the test, the system will guide the device to carry out all controls and operations automatically. To enable you to grasp the running status, various real-time parameters will be presented on the screen during the test. After the test is completed, the machine will automatically stop and alarm.

IPX1 & IPX2 testing

IPX1-IPX6 combined test chamber

In addition to IPX1/2 waterproof testing, AmadeTech can also integrate more hardware required for other waterproof test items into a box according to user requirements, so as to perform IPX1, IPX2, IPX3, IPX4, IPX5, IPX6 or even IPX9 testing on one device (Please refer to the figure on the left). The combined chamber not only reduces the test site size requirements, but also saves procurement costs for users.

Welcome to reach us and list your thoughts, our personalized solution will be tailored to your individual test requirements.

For more water ingress protection testing devices, please click the below links:

IPX3 & 4 & 4K Spraying Test Equipment

In addition to the box-type drip test equipment, AmadeTech can also supply frame-type and wall-mounted IPX1/2 drip test equipment to accommodate samples of larger volume or irregular shape. Their functions are the same, but there are some differences in structure, appearance and cost. Please check some features as below:

Frame-type Drip Test Equipment

- The frame is made of aluminum alloy.

- Suitable for working in the rain test room with waterproof function.

- The turntable assembly is flexible to move.

- Equipped with castors for movement of the whole machine.

- Fitted with an electric hoist at the top.

- The drip box can be raised and lowered automatically under control to achieve a spacing of 200 mm from the top of the specimen.

- Equipped with a separate controller with a touch screen.

- Supports energized testing of the specimen.

- The intelligent control of the test process is available.

- The size of the drip box and frame is customizable.

- Supports the pneumatic drainage.

Wall-mounted Drip Test Equipment

- The frame is made of aluminum alloy.

- Required to be fixed against the wall.

- Takes up a smaller place relative to other devices.

- Requires waterproofness for the test site.

- Fitted with an independent controller with a touch screen.

- Equipped with a photoelectric sensing device to allow the drip box ascend and descend automatically under control to achieve a spacing of 200 mm from the top of the specimen.

- The turntable with casters is movable.

- Suitable for testing larger samples.

- Testing energized specimens is available.

- Customizing the dimensions of the drip box and turntable is available.

- Supports the pneumatic drainage.

If you are interested in more IPX rain test chambers, please go HERE.

If you want to learn more about IP testing equipment, please click HERE.

Conforming Test Standards

IEC60529, ISO 20653, IEC 60598-1, IEC 60068-2-18, IEC 60034-5, DIN 40050-9

Main Technical Specifications

Model | AT-C1005A2-400 | AT-C1005A2-600 | AT-C1005A-600 | AT-C1005A-800 | AT-C1005A-1000 | AT-C1005A-1200 | AT-C1005A1-600 | AT-C1005A1-800 | AT-C1005A1-1000 | AT-C1005A1-1200 | AT-C1005A1-1600 |

Equipment type | Box-type with an enclosed chamber | Wall-mounted | Frame-type | ||||||||

Drip area | (W) 400 X (D) 400 mm | (W) 600 X (D) 600 mm | (W) 600 X (D) 600 mm | (W) 800 X (D) 800 mm | (W) 1000 X (D) 1000 mm | (W) 1200 X (D) 1200 mm | (W) 600 X (D) 600 mm | (W) 800 X (D) 800 mm | (W) 1000 X (D) 1000 mm | (W) 1200 X (D) 1200 mm | (W) 1600 X (D) 1600 mm |

Turntable diameter | Dia. 300 mm | Dia. 400 mm | Dia. 400 mm | Dia. 600 mm | Dia. 600 mm | Dia. 800 mm | Dia. 400 mm | Dia. 600 mm | Dia. 800 mm | Dia. 1000 mm | Dia. 1000 mm |

Overall dimensions | (W) 1050 x (D) 850 x (H) 1550 mm | (W) 1250 x (D) 1050 x (H) 1750 mm | (W) 850 x (D) 950 x (H) 2450 mm | (W) 1050 x (D) 1150 x (H) 2450 mm | (W) 1250 x (D) 1350 x (H) 2450 mm | (W) 1450 x (D) 1550 x (H) 2450 mm | (W) 1150 x (D) 850 x (H) 2450 mm | (W) 1350 x (D) 1050 x (H) 2450 mm | (W) 1500 x (D) 1200 x (H) 2450 mm | (W) 1700 x (D) 1400 x (H) 2450 mm | (W) 1800 x (D) 1800 x (H) 2700 mm |

Spacing of drip holes | 20 x 20 mm | ||||||||||

Drip pinhole | Dia. 0.4 mm | ||||||||||

Drip pan height | Fixed | 800 ~ 1800 mm adjustable | |||||||||

Turntable height | Adjustable | 600 mm (fixed) | |||||||||

Turntable angle | 0° (horizontal) or 15° inclined adjustable | ||||||||||

Turntable loading capacity | Max. 50 kg | ||||||||||

Turntable rotating rate | 1 ~ 5 RPM adjustable | ||||||||||

Control mode | PLC + 7-inch touch screen | ||||||||||

Feature | Allows energized samples during the test | ||||||||||

IPX 1/2 Drip Test Equipment Features

Frequently Asked Questions (FAQs)

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales specialists will respond within one working day.