IPX5 / IPX6 / IPX6K Waterproof Test Set-up China Manufacturer

IPX5 / IPX6 / IPX6K Water Jetting Test Chamber is able to project water in jets against the enclosure of the specimen from any direction to determine whether the specimen reaches the specified waterproof level. It can generate different water pressures to meet different testing requirements.

This equipment is suitable for waterproof testing of outdoor lighting, signaling equipment, automotive lamp housings, etc.

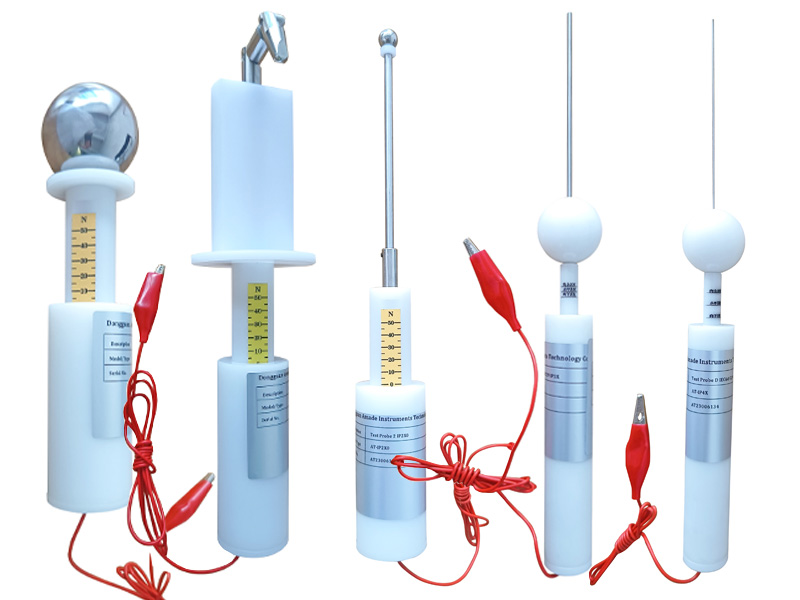

AmadeTech configures two pieces of hose nozzles for one machine to fit different test requirements. They are made of precision metal and have different specifications: One’s outlet diameter is 6.3 mm for IPX5 & 6K testing, and the other one’s diameter is 12.5 mm for IPX6 testing. You can select either one to complete the test conveniently.

Dia. 6.3 mm & 12.5 mm nozzles

The equipment dimension can be tailored to your sample specifications. In addition, you are allowed to decide whether to configure an additional waterproof socket inside the test chamber to accept energized samples.

If you are looking for IPX3/4/4K test chambers, please click HERE.

If you want to learn more about IP testing equipment relative to IEC 60529 and ISO 20653, please click HERE.

In addition, if your product requires different levels of waterproof testing, but due to laboratory space limitations or the inability to afford the cost of multiple devices, AmadeTech can help you. AmadeTech has ability to integrate the hardware of waterproof testing equipment for different levels such as IPX1/IPX2/IPX3/IPX4/IPX5/IPX6/IPX9 into one box-type device as per actual demands, so that once device performs multiple functions. Please refer to the right picture of a combined test chamber.

If you have any personalized testing needs, please tell us immediately to get the corresponding solution.

Open-type test equipment

Box-type & open-type IPX5/6/6K water jetting test machines are available at AmadeTech. The box type is an all-in-one test chamber integrating different parts. We add an extra aqueduct to connect to the chamber holding the specimen. The nozzle is positioned at the other end of the duct to project a stream of water from 2.5~3 meters onto the sample through the aqueduct to prevent water from leaking onto the ground and facilitate water collection for circulation use throughout the test. The nozzle oscillation during the test can be automatically achieved if required.

The open type is a split testing machine, as the nozzle and the sample turntable are separated from the control system and the water tank. The sample mounting is free from space limits and can accept samples with larger dimensions, but it requires a waterproof test site with a drainage system.

The turntable placing the sample can rotate at a set speed during the test. The nozzle must be manually oscillated up and down to enable the device under test to be sprayed from all directions.

PLC controls the whole testing process. Before the test, you only need to make the corresponding settings and selections on the touch LCD. The equipment will automatically complete the test according to the predetermined program, saving you the trouble of looking after the machine during testing.

- IEC 60529

- ISO 20653

- DIN 40050-9, etc

| Test Item | IPX5 | IPX6 | IPX6K |

| Nozzle internal diameter | 6.3 mm | 12.5 mm | 6.3 mm |

| Water pressure | Approx. 30 kPa | Approx. 100 kPa | Approx. 1000 kPa |

| Water flow rate | 12.5 l/min ± 5% | 100 l/min ± 5% | 75 l/min ± 5% |

| Exposure time | 1 min/m2, at least 3 min | 1 min/m2, at least 3 min | at least 3 min |

| Distance from nozzle to enclosure surface | 2.5 ~ 3 m | 2.5 ~ 3 m | 2.5 ~ 3 m |

Main Technical Specifications

Model | AT-1005C | AT-1005C-600 | AT-1005C-800 | AT-1005C-1000 | AT-1005C-1180 |

Equipment type | Open-type | Box-type with an enclosed chamber | |||

inside chamber dimensions | / | (W) 600 x (D) 600 x (H) 600 mm | (W) 800 x (D) 800 x (H) 800 mm | (W) 1000 x (D) 1000 x (H) 1000 mm | (W) 1180 x (D) 1180 x (H) 1180 mm |

Overall dimensions | (W) 1100 x (D) 900 x (H) 1300 mm | (W) 3550 x (D) 1050 x (H) 1600 mm | (W) 3550 x (D) 1050 x (H) 1600 mm | (W) 4050 x (D) 1250 x (H) 1850 mm | (W) 4350 x (D) 1400 x (H) 1900 mm |

Turntable diameter | Dia. 600 mm | Dia. 400 mm | Dia. 600 mm | Dia. 600 mm | Dia. 800 mm |

Turntable height | Fixed | ||||

Nozzle opening size | Dia. 6.3 mm (IPX5 & IPX6K), Dia. 12.5 mm (IPX6) | ||||

Water flow and pressure required | IPX5: 12.5 L/min ± 5%, pressure appr. 30 kPa IPX6: 100 L/min ± 5%, pressure appr. 100 kPa IPX6K: 75 L/min ± 5%, pressure appr. 1000 kPa | ||||

Water jetting distance | 2.5 ~ 3 meters | ||||

Control mode | PLC + 7-inch touch screen | ||||

Feature | Allows energized samples during the test | ||||

Water Jetting Test Equipment Features

Frequently Asked Questions (FAQs)

Leave Your Message Here

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales specialists will respond within one working day.