Leather Test for Adhesion of finish (Coating)

This tensile testing equipment is a universal testing machine for measuring the adhesion of the finish coat on the leather or the adhesion between two adjacent finishes. The tester is applicable to all finished leather with a smooth surface.

Test Principle

The solvent-free adhesive is used to bond part of the leather coating layer to the adhesive plate, and the force is applied to the free end of the strip leather to make the leather coating layer peel off to the specified length. The coating layer is stuck to the adhesive plate, and the force applied is the adhesion fastness of the coating layer to the leather.

Test Standards

ISO 11644, GB/T 4689

Main Technical Parameters

| Model | AT-L9019-B | AT-LK9019-BB |

| Capacity | 200N, 500N optional | |

| Load Precision | ± 1% | ± 0.5% |

| Test Speed | (25 ~ 500) mm / min adjustable 100 mm / min (Standard) | (0.01 ~ 500) mm / min adjustable 100 mm / min (Standard) |

| Test Travel | 600 mm | 600 mm |

| Display | Test software | Test software |

| Driver | Frequency conversion motor | Servo motor |

| Configurations | Tensile testing machine, PVC Adherent-plate, Adherent-plate holder, grip for leather clamping | |

| Safety Devices | Leakage protection, overload, emergency stop, upper and lower stroke limit device | |

Construction of Tensile testing machine for adhesion test of leather coating:

1. Tensile testing machine

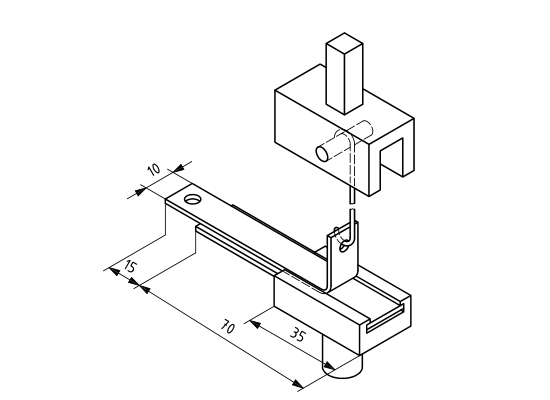

2. Adherent-plate

3. Adherent-plate holder

4. Hook link or a suitable grip that is suitable for clamping the leather sample on the upper jaw of the tensile testing machine

To perform this test, you will need to prepare the arrangements below:

1. Tensile testing machine (contains all the components) – Supplied by Amade-tech.

2. Adhesive

3. Oven (Optional with extra cost) – supplied by Amade-tech.

4. Weight-piece, 4.5kg

5. Cleaning solvent

6. Sample cutter

7. Vacuum-desiccator vessel

8. Vacuum pump

Features

- The machine’s structure is made of an aluminum extruded plate, which is processed by advanced baking paint.

- The built-in high-precision, low-resistance, no-clearance ball screw and guide column improve the load efficiency and structural rigidity.

- The load element adopts a high-precision force sensor.

- A computer compatible with a test software can complete all the test parameter settings, working state control, data acquisition and analysis processing, diagram display, test results editing and print out.

- The test machine performance is stable and reliable, and the measurement accuracy is high.

- The test software function is powerful, and the operation is easy to understand.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.