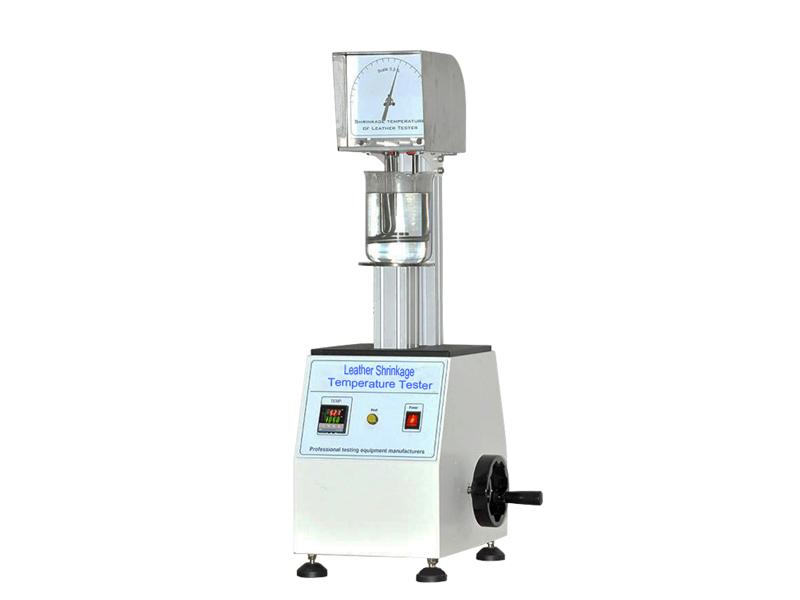

Taber Linear Abraser is used to determine the test sample’s abrasion resistance, the scratch resistance after single or multiple scratches, or the color transferability by measuring the color fastness of the specimen subjected to abrasion. It can perform dry abrasion tests and wet abrasion tests.

AmadeTech Taber linear abrader can accept test samples of any size or shape, especially suitable for the abrasion test of products with contoured or flat surfaces with a polished finish, such as computer mouse and painted surfaces of electronic products. It is commonly used in plastics, auto parts, rubber, leather, textiles, electroplated products, printed items, paint finishes, etc.

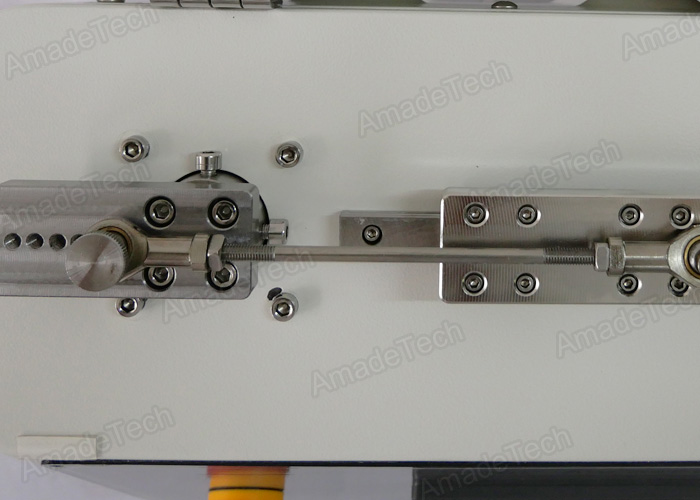

This linear abrasion tester features a metal arm protruding from the side at the top, and it is able to make reciprocating motion horizontally in a linear path. It allows you to manually adjust the stroke distance according to test requirements. There are 8 adjustable distances available, including 0.5”, 1”, 40 mm, 2”, 2.5”, 3” 3.5” and 4” .

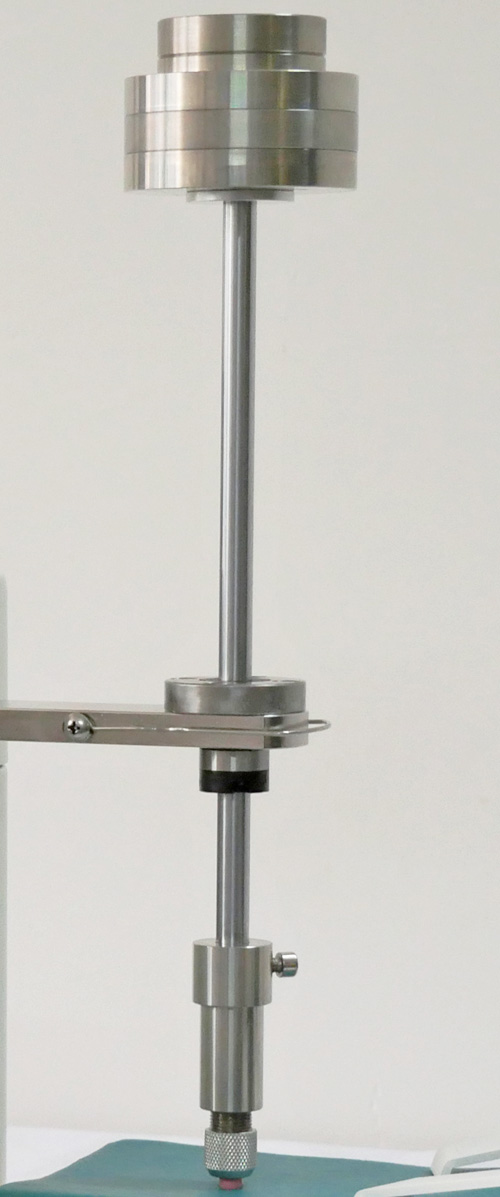

A metal rod with two longitudinal guide grooves is provided. You need to insert the rod straight down and through the bore at the free end of the arm during the setup process. The auxiliary attachments holding the abrading medium corresponding to your testing are required to be secured at the bottom of the rod. The genuine pencil erasers of different models from Taber Industries as a commonly used medium are available to be provided with the machine if required.

5 disc weights of different masses (Default configurations: 50 g & 100 g & 3 x 250 g ) are permitted to be superimposed on top of the rod in a certain combination to exert an anticipated pressure on the specimen. The rod is not fixed, and it can move up and down freely with the change in the flatness of the contact surface between the abrading finger and the specimen when the contoured specimen is tested.

To expand the scope of application of this linear abrader, we can provide different auxiliary accessories, which can be exchanged to achieve different test applications. Including but not limited to the following attachments:

Items | Picture | Application |

Metal collet |  | Determination of the abrasion resistance |

Alcohol rubbing finger kit |  | Determination of the resistance of dissolution performance of fonts on the printing surface or coating against water, organic solvents, or corrosive liquids. |

Pencil test kit |  | Determination of the film hardness of paints and coatings |

Scratch tip |  | Determination of the scratch resistance |

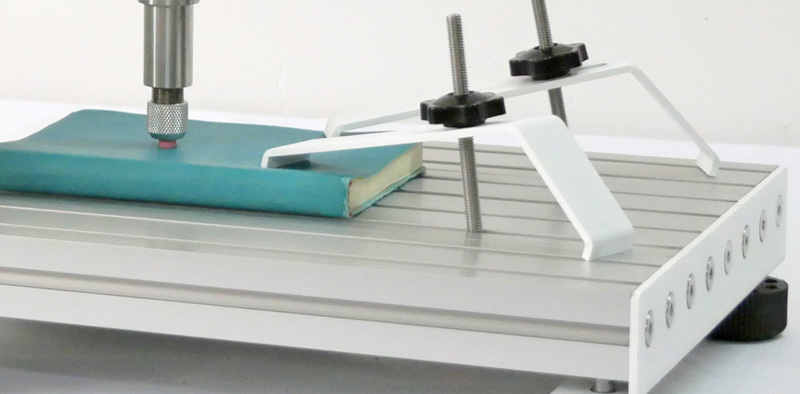

The machine comes with a universal specimen mounting platform. There are parallel grooves distributed across the table. Specimens in different shapes and sizes can be placed and fixed on the platform in conjunction with two fixing devices with screws. The platform is required to be positioned next to the machine, and the back-and-forth movement path of the metal rod is required to be in line with the tested area of the specimen.

Specimen mounting table

The Taber linear abraser is equipped with a piece of touch screen for displaying test speed, preset and real-time number of runs. The abrading head goes back and force to form a test cycle. The test cycle can be set freely, ranging from 1 to 999,999, and the test speed can also be adjusted as high as 100 CPM as per test requirements with the aid of this touchscreen. It facilitates you to control and monitor the test easily and conveniently.

Technical Parameters

| Model | AT-L9001C |

| Control mode | Touch screen |

| Stroke Lengths | 0.5”, 1”, 40 mm, 2”, 2.5”, 3” 3.5” and 4” or customizable |

| Test Cycles | 0 ~ 999,999, adjustable |

| Test Steed | 10 ~ 100 cycles / min , adjustable |

| Weight options | 50 g, 100 g, 250 g x 3 pcs |

| Test Load | 350 g ~ 2100 g, adjustable |

| Power Supply | AC 110 ~ 240V, 50 Hz / 60Hz |

Taber Linear Abraser Features

- The housing is made of high-quality steel, and it is beautiful and elegant after baking.

- A high-quality motor is used to ensure intense power and stable operation.

- Equipped with a high-definition touch screen with an English interface to display and set parameters.

- Allows users to set the moving speed and number of cycles freely according to the test needs.

- Multiple stroke distances are interchangeable by manual operation.

- A universal sample mounting table is available to accommodate samples of shall shapes.

- Compatible with various tests, such as the abrasion test, alcohol resistance test, scratch resistance test, film hardness test, etc.

- Comes with multiple weights with different masses to provide possibilities for obtaining different loading combinations.

- Original abradants from Taber Industries can be provided as per user needs.

FAQs

Others Also Viewed

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.