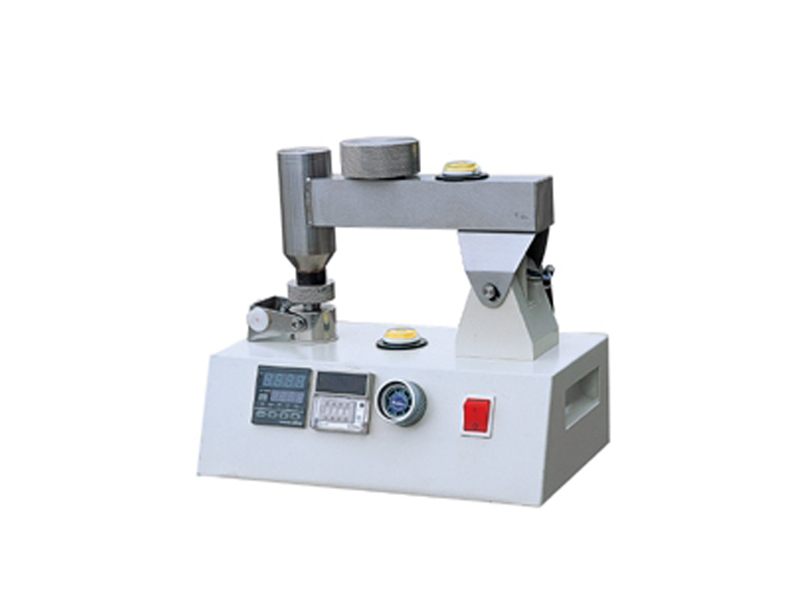

AT-F3042 Circular Blade Cutting Resistance Tester Manufacturer and Supplier

Upper/Glove Cutting Resistance Tester is specially used for testing the cutting strength of uppers, protective gloves, leather, etc. It does not apply to gloves made of hard materials.

The specimen is cut by a counter-rotating circular blade which moves in an alternating motion under a specified load. The blade cut resistance tester has a wire with a similar earphone plug on each side. Before testing, You are required to insert both ends of it into the machine body and the clamping frame, respectively, which forms a circuit once the blade cuts through the specimen so as to stop the machine.

The traditional digital display model and touch screen control model are available from AMADETECH.

Test Principle

A circular blader is located at the bottom of the metal arm that can move back and forth, and the sample is placed under the circular cutting wheel under certain pressure. When the metal arm makes a reciprocating movement, it drives the cutting wheel to perform the move in the opposite direction to cut the specimen. The number of cycles the specimen can withstand in each test is recorded to calculate the test results.

Request Quote

Test Standards

- EN 388 section 6.2

- ISO 20344 section 6.14

- GB/T 20991 section 6.14

- AS/NZS 2210.2 section 6.14

- AQ 6102 section 4.3.2, etc.

Main Technical Parameters

| Model | AT-F3042 |

| Circular blade | Diameter (45±0.5) mm

Thickness 0.3 mm Cutting angle 30° to 35° |

| Stroke | 50 mm |

| Load | (5±0.05) N |

| Cutting speed | (8±2) cm / s |

| Counter | LCD display, 0 ~ 999,999 |

| Protection devices | Automatic alarm & stop |

| Power supply | 1 Phase, AC 220V or specified |

Features of Upper & Glove Cutting Resistance Tester

- Made of precision steel to ensure the rigidity and durability of the machine.

- The test accuracy can reach 0.1 circle.

- The blade is made of tungsten alloy steel, and the hardness is 740 HV ~ 800 HV. The replacement of the blade is very simple.

- Equipped with 2 sets of fixtures.

- When the sample is punctured during the test, the instrument stops automatically.

- Fitted with an LCD to present the real-time parameters and facilitate your operation.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.