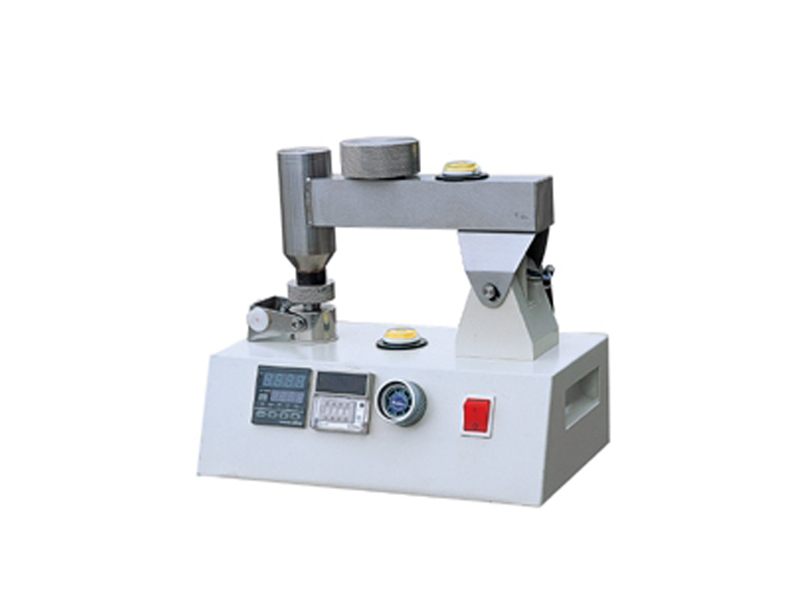

Shoe Insole Fiberboard Flex Tester China Manufacturer

Fiberboard Flexing Tester is a footwear testing machine intended for determining the flexing endurance of fibreboards. Results of the test offer a good guide to the general quality of the fibreboards applied to footwear.

This testing machine is applicable to most types of semi-rigid sheet materials and particular fiberboards other than those used for insole seats and heel lifts.

Test Principle

Fibreboard is flexed mechanically and repeatedly until a failure happens. From the number of flex cycles to failure, a flexing index is calculated.

During the test, the specimen is rotated up to 180° (2 × 90° from each side vertically) under a certain load until it breaks. In the meantime, the number of flexes to failure of each specimen will be displayed on each separate counter.

Test Standards

- BS-5131-4.2 Footwear and footwear materials-flexing index of fibreboard

- QB/T 1472 Flexing index of fiberous board for footwear

- SATRA TM3 Fibreboards flex index

Main Technical Parameters

| Model | AT-F3023 |

| Test Station | 6 |

| Jaw Wedge Angle | 38° + 38°, Radius: 0.8 ± 0.1 mm |

| Specimen Size | 80 × 10 mm (70 ± 10) mm × 10 mm |

| Lower Clamp Weight | 2.00 ± 0.01 kg |

| Upper Clamp’s Bending Speed | 60 ± 10 rpm |

| Upper Clamp’s Bending Angle | Each side 90° ± 1° |

| Counter | 6 groups

Indicated the total number of completed flex cycles during the test |

| Control Method | Touch screen |

| Power Supply | 1 phase, AC 220 V, 3A |

| Dimension | 105 × 25 × 35 cm |

| Weight | 149kg |

| Standard accessories | Upper / Lower clamps and weights 6 groups

Power line 1 pc |

Fibreboard Test Procedure

- Measure the 3 test pieces from one of the 2 main directions of the fibreboard simultaneously by the following methods.

- Align the test piece in the jaws of the bending apparatus so that the 80 mm sides are vertical to the horizontal edges of the jaws and approximately 15 mm of the length of the test piece is clamped by the jaws.

- Insert small strips of the fibreboard between the jaws above the test piece, If necessary, to ensure that the 2 clamping faces of the jaws stay parallel.

- Secure the test pieces tightly in position, and attach the weighted clamps to the free ends. Run the flexing machine until all 3 test pieces have broken and record using the counter, the number of flex cycles to breakage for each test specimen.

- Repeat the procedure with the second set of test pieces which were cut in the other principal direction of the fibreboard.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.