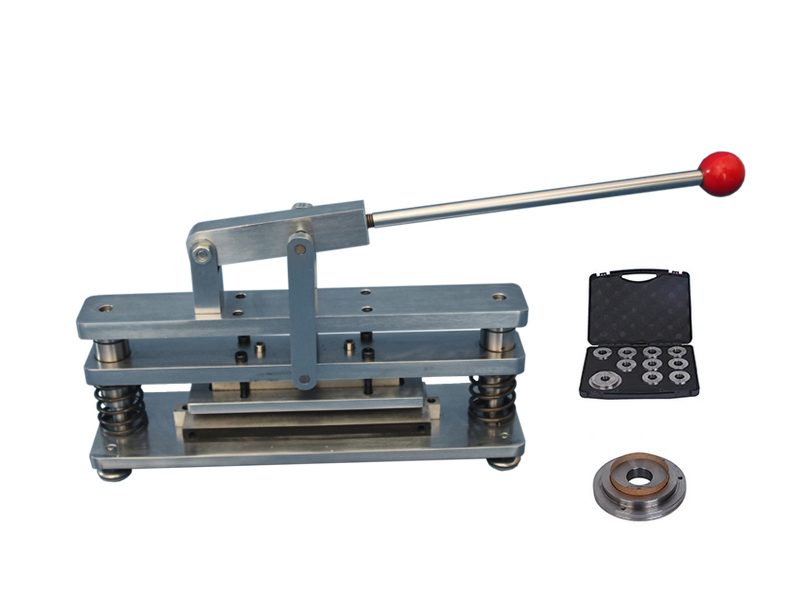

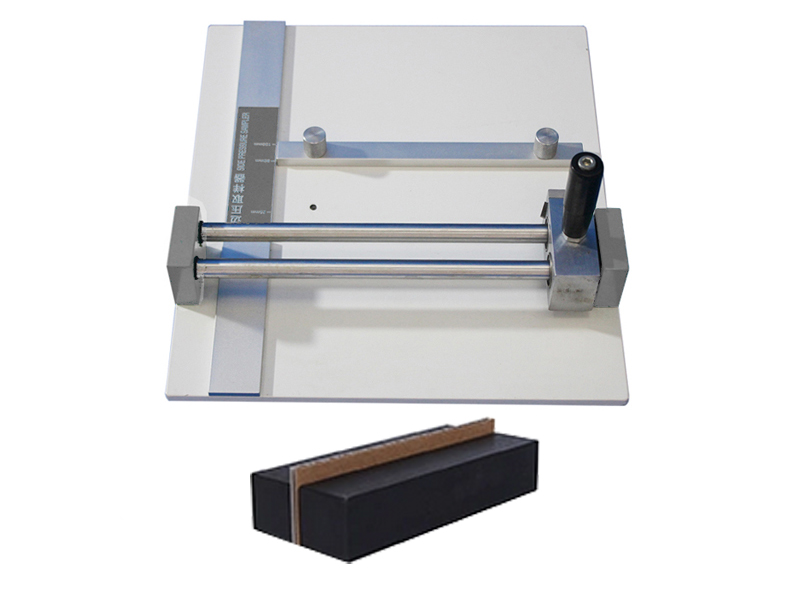

AT-P8004-A Ring Crush Test Piece Holder

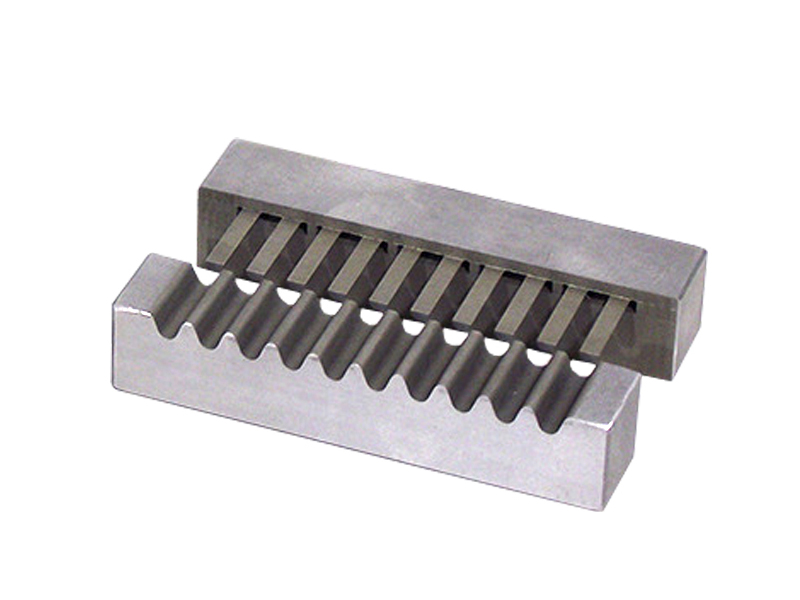

Paper and Board Ring Crush Test Piece Holder consists of a cylindrical base block with a cylindrical recession that, together with a removable central disc, forms an annular groove. The recession has an inside diameter of 49.3 mm and is 6.35 mm deep, with its bottom parallel to the base of the block to within 0.01 mm. The disc is 6.35 mm thick. In order to accept different thicknesses of test pieces, discs of various diameters are provided by AMADE TECH. The distance of the width of the groove between the edge of the disc and the wall of the cylindrical recess is adjustable. A centring pin is fixed in the exact center of the cylindrical recess. A tangential groove not more than 1.27mm in width is cut from the edge of the block tangential to the cylindrical recess to allow insertion of the test piece.

Test Standards

ISO 12192, DIN 53134, SCAN P34, TAPPI T 822, APPITA / AS 1301.407s

Main Technical Parameters

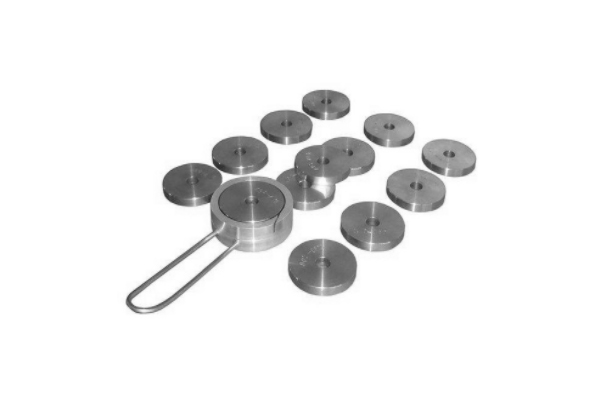

| Model | AT-P8004-A |

| Specimen thickness(mm) | Disc diameter(mm) |

| 0.100~0.140 | 48.90±0.05 |

| 0.141~0.170 | 48.80±0.05 |

| 0.171~0.200 | 48.70±0.05 |

| 0.201~0.230 | 48.60±0.05 |

| 0.231~0.280 | 48.50±0.05 |

| 0.281~0.320 | 48.40±0.05 |

| 0.321~0.370 | 48.20±0.05 |

| 0.371~0.420 | 48.00±0.05 |

| 0.421~0.490 | 47.80±0.05 |

| 0.501~0.580 | 47.60±0.05 |

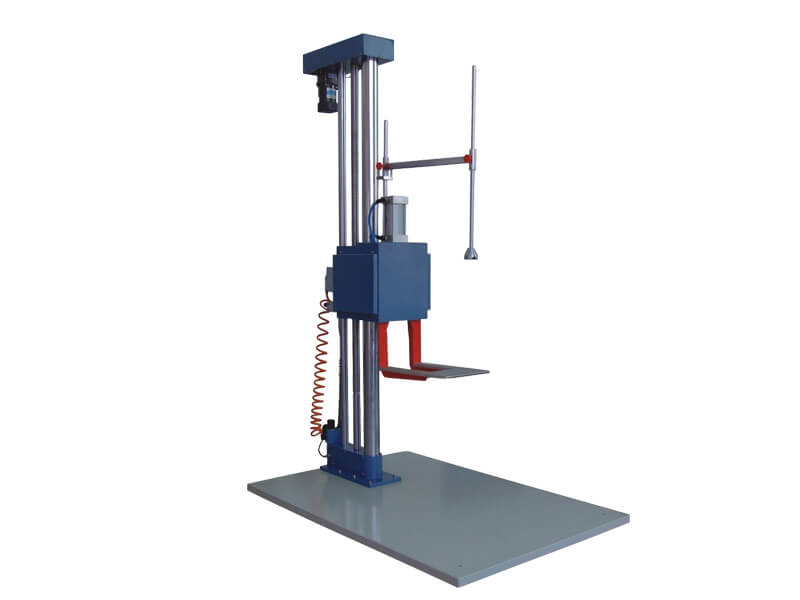

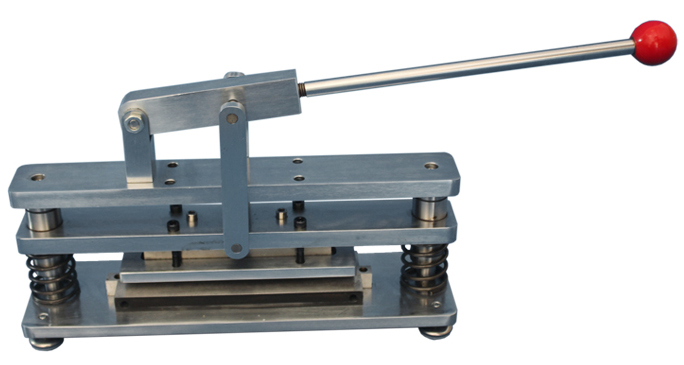

AT-P8004-B Ring Crush Test Sampling Device

Main Technical Parameters

| Model | AT-P9004-B |

| Standards | TAPPI-T409, JIS-P8113 |

| Sampling Size A | 152 x 12.7 mm for ring crush test |

| Sampling Size B | (200 ~ 250) × 15 mm for tensile test |

| Sample thickness | (0.1 – 1.2) mm |

| Equipment Dimension | 350 × 100 × 220 mm |

| Net Weight | 14 kg |

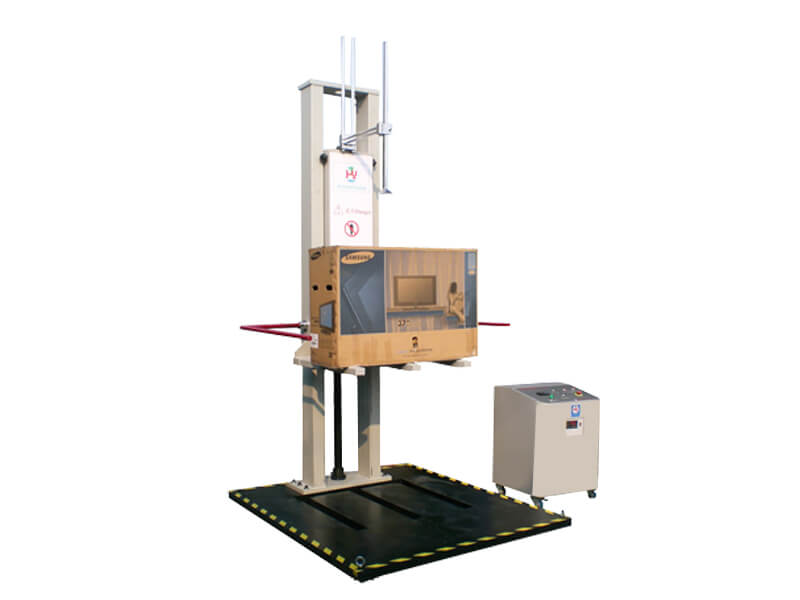

What is Ring Crush Test

Ring Crush Test (RCT) is designed to determine the edgewise compressive strength of paper and paperboard, especially the board used in the manufacture of fibreboard shipping containers.

The paper or board material is cut with a special ring sampling cuter to get a sample of a specified size. The sample is mounted in an annular groove of the holder and then crushed between the crush tester’s upper and lower compression platens. The edge of the specimen is subjected to increasing pressure until it is collapsed.

It helps people in knowing the performance of corrugated cartons when subjected to flute-oriented compressive strength during transportation and storage.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.