Mooney Viscosity Tester China Manufacturer

Mooney viscometer is intended to measure the Mooney viscosity of uncompounded rubbers and compounded rubbers. The Mooney viscosity value is one of the important indexes to evaluate the processing performance of rubbers.

The Mooney viscosity value of the rubber is closely related to its plasticity. A high viscosity value indicates that the rubber has a large molecular weight and poor plasticity. On the contrary, it indicates that the rubber has a small molecular weight and good plasticity. Reasonable rubber Mooney viscosity value is conducive to rubber mixing, calendering, extrusion, injection and molding vulcanization processing.

High-precision sensor, control system, rotating system, temperature control system, display system, rotors, measurement and control system are the main components of the Mooney viscometer.

AT-R7001 is a rotational shearing viscometer used for performing three tests:

1. Viscosity test (ML/MS 1+X)

2. Stress Relaxation test

3. Mooney scorch test

Test Principle

2 discs of rubber test pieces prepared based on the prescribed requirement are respectively placed below and on the rotor disc in the die cavity. The torque which has to be applied under specified conditions in order to rotate a metal disc in a cylindrical chamber formed from mating dies filled with rubber is measured. The resistance produced by the rubber to this rotation is expressed in arbitrary units as the mooney viscosity of the test piece.

INQUIRE

Test Standards

- ISO 289:2005, ASTM D 1646, DIN 53523.

- BS 903: Part 58, AFNOR T43-00/005.

- BS 1673, GOST 10722-76, JIS K6300 etc.

Core Technical Specifications

| Model | AT-R7001 |

| Item | Mooney viscometer |

| Mooney Viscometer | RT ~ 200℃ |

| Temperature System | PID monitoring |

| Temperature Display Resolution | 0.01℃ |

| Temperature Control Accuracy | ± 0.3℃ |

| Calibration Accuracy | Mooney value ± 0.5 |

| Rotor Speed | 2 ± 0.02 rotations / min |

| Rotors | Large one: 38.10 ± 0.03 mm in diameter, small one: 30.48 ± 0.03 mm in diameter |

| Closing Force | 11.5 KN |

| Torque Range | Mooney value 0 ~ 200 |

| Torque Resolution | Mooney value 0.1 |

| Communication Interface | Ethernet, RS 232 |

| Test Report content | Date, time, temperature, Mooney scorch curve, Stress Relaxation and MV,T5,T35,T3,T18,@15,@30, Initial viscosity, ML/MS 1+X, X+Y+Z, |

| Power Supply | 50 Hz,AC 220V ± 10%, 1 phase |

| Air Source | Min. 0.6 Mpa |

Mooney Viscometer Features

- The professional test software is provided for work with a computer conveniently to facilitate data acquisition, storage, processing and printing of test results.

- The test software works based on the windows operating system.

- The rotating system adopts the number of teeth deceleration speed motor + number of teeth reducer + reduction gear. The rotating speed is 2±0.02r/min.

- An Intelligent digital temperature control device for automatically correcting the PID parameters brings quick and precise temperature control.

- Fitted with two rotors: Large one is 38.10 ± 0.03 mm in diameter, the small one is 30.48 ± 0.03 mm in diameter.

- Temperature probes and the sensor are located in the die chamber to monitor and control the real-time temperatures.

- Configured with a precision sensor with high sensitivity for accurate measurement of torque.

- Measurements of Mooney Viscosity, scorch and stress relaxation are available.

- Equipped with a lucid shield to separate working area from the operators to ensure absolute safety during the test.

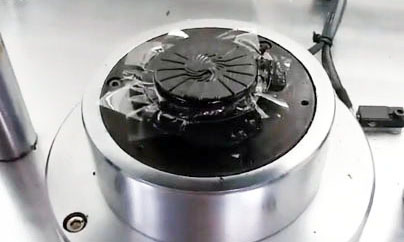

As core components of Mooney viscometer, the die cavity formed from 2 halve and the rotor play essential roles during the test. In order to prevent slippage in the process of measurement, this machine features radial V-grooves on the flat surfaces of dies, rectangular-section grooves on the surface of the rotor and vertical grooves on the edge of the rotor in accordance with relevant specifications. There are thermocouple measurement probes and a temperature sensor for accurate temperature acquisition and control.

Different from the traditional Mooney viscometers, our machine integrated with modern measurement technology features special software compatible with the Windows Operating systems allowing the testing status and parameters in real time to be displayed on a computer monitor. For example, The real-time torque values of rotating the rotor and temperatures of upper & lower dies are recorded and visualized throughout the test.

Mooney Viscosity Test Method

- Turn on the Mooney viscometer and computer which is connected to this machine.

- Open and run the Mooney viscosity test software on the computer.

- Input the right plastics name, choose “Mooney viscosity” as a testing method, select the right testing temperature based on standard applied and choose “ML1+4” as Mooney testing time in sequence, then click Save Settings and start System to perform the test.

- Open the dies, and insert the rotor spindle into the hole of the lower die.

- Remove the rotor once reaching the preselected testing temperature, and insert the rotor spindle through the hole in the perforated disc of the specimen, then reinsert the rotor with the specimen together.

- Place the unperforated disc of the specimen centrally on the rotor and close the dies.

- Enter countdown of 1 minute of preheating time.

- Press the “Rotor” button to perform the test after 60 seconds.

- The test will be ended in 4 minutes, and data will be recorded and saved automatically.

- Back to main interface and power off.

The above is just a reference. Please strictly follow the procedure of the applied standard to carry out the test when you get this testing machine.

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.