2 Roll Rubber Mixing Mill China Manufacturer & Supplier

Laboratory Two Roll Mill (LTRM) is an electric mixing equipment able to masticate and mix polymers, including rubber, plastic, elastomer materials, or mixtures with similar melting points by means of a pair of rotating rolls preheated to a required temperature, converting raw materials into various compounds. It is an indispensable machine for formula development, color matching, small batch testing, pilot production, contrast, and quality control in the plastic and rubber industries.

Addictives in the form of particles, powder, and liquid are allowed to be added as activators, fillers, or oils into the base. With the rotation of the two rolls, the internal macromolecular chains of the raw materials are broken accordingly for mastication, and the compositions inside the rubber compound are further dispensed to complete mixing, thus producing sheet-like materials for further molding desired products. During the process, the operator needs to keep cutting, folding, and rolling the material on the front roll manually with a tool made of bamboo or wood to enhance the uniformity of the compositions.

AmadeTech offers lab two roll mills ranging from benchtop to conventional models. Suppose you want to conduct the polymer compounding for a relatively large batch requiring no manual operation or no potential atmosphere pollution. In that case, you can click to learn about AmadeTech’s kneader machine.

Lab Two Roll Mill Working Principle

The raw materials and additional ingredients placed between the two rolls are drawn into the roll gap with the rotation of the rolls, subjected to intensive squeezing and shearing. The deformation of materials increases the contact area between the compositions. When the stress applied to the materials is greater than the allowable limit, and the materials’ internal macromolecular chains will be stretched and broken, so that the compositions will be further dispersed and mixed evenly. This process is repeated until the expected mastication or mixing state is achieved, and the desired compound is achieved in a sheet form.

Details on Laboratory-type Open Mixing Mills from AmadeTech

AmadeTech laboratory-type rubber mixing mill features two parallel rolls of the same size that can rotate inwards in opposite directions. Two rolls have heating and cooling functions under control. You can customize the size of the rolls according to your test needs. The roll on the operator’s side is called the front roll, and its position can be adjusted horizontally within a preset range. The other roll is called the rear roll, and its position is fixed.

When rotating, the speed of the two rolls is different. The rear roll rotates faster than the front one to produce an intended shearing force. The regular ratio of the peripherical speeds of the rolls is about 1.2:1. The friction ratio and the shearing force are positively correlated. Based on different configurations (single or dual motor), this ratio is fixed or adjusted yourself according to the test requirements. The roll speed is allowed to be adjusted within the default range. Prior to the test, you are required to manually or electrically adjust the distance between the two rolls to achieve the desired sheet thickness of the compound.

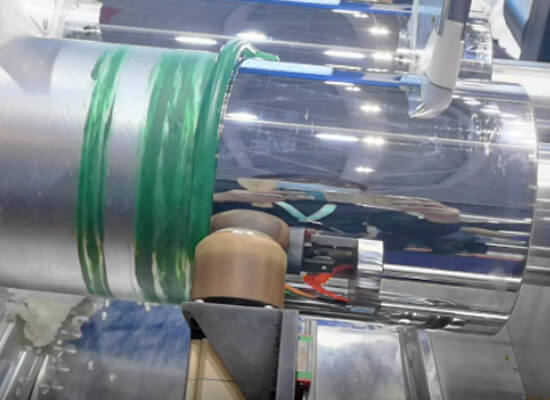

- The roll is made of KDB high-carbon steel with a high-temperature quenching treatment.

- The surface is plated with high-hardness chrome and mirror polished, whose hardness is up to 60 HRC. (thickness of chrome plating is 0.1 mm)

- A built-in heating device to heat the roll evenly to a preset value. (Supports electric/oil/steam heating)

- The roller inside is drilled to allow the circulating water to flow to achieve cooling purposes.

- Supports auto reverse and quick ejection (optional) of the rolls once pressing the emergency stop.

- With manual roll nip adjustment devices to adjust the distance between the two rolls (The electric adjustment is optional).

- The metal disc with slots can accept up to 8 points as the starting point of turning, which greatly facilitates the operation.

- The extended handle uses the principle of leverage to achieve a labor-saving effect.

- The distance between the rolls is accurately displayed on the corresponding meter for easy adjustment.

- The control interface consists of physical keys and digital screens.

- PLC + touch screen are optional.

- Japanese RKC thermostats are used, and the temperature can be preset and displayed in real time.

- Front and rear roll speeds can be set independently if double FM is configured.

- Reasonable button layout, convenient operation, and user-friendly.

- The side in front of the operator is equipped with 2 pressure-sensitive gates.

- The operator can tap the gate with either knee in an emergency.

- The roller will automatically stop rotating and reverse 1/4 turn to eliminate the danger once the gate is tapped.

- In addition, multiple safety measures, such as protective brackets over the rolls with the emergency stop function, can be added to our open mixing mills.

Steam & water inlets

In addition to the mainstream electric heating and oil heating two rolling mills, we also provide lab roller mills that use steam to heat the rolls. An interface is reserved for each roll to connect to the steam source you prepare. When the external steam circulates into the roll to heat it, the temperature detection device will transmit the temperature information in real time and display it on digital screens, which is convenient for you to monitor and control the temperature. The rolls also support water cooling if required. Like regular heating models, you can customize various parameters, functions, and safety features, such as roll sizes, roll friction ratio, control method, etc.

PLC+Touch screen

In order to meet the needs of high-end use, we also provide PLC automatic two roll mixing mills. The machine is equipped with German Siemens PLC and a high-definition touch screen to replace the traditional button-type control panel. Various real-time parameters and command switches are integrated on the screen, including real-time roll temperature, roll nip, roll speed, roll friction ratio, power switch, reset, cooling instructions, etc. With the support of PLC, it is possible to install more personalized configurations, such as a device that can electrically adjust the distance between the two rolls.

Automatic scraper

PLC offers the possibility of adding more advanced configurations, such as the automatic material turning system, which features a rotatable head that can move horizontally left and right. When the rolls are fed and running normally, the head on the device replaces the scraper held by the operator, automatically approaches, and rests on the surface of the font roll under the control of a preset program. It is able to move from either end of the roll to the other end folding the rubber mixture and automatically reciprocating until the mixing operation is complete. This humanized design improves machine operation’s convenience and safety, liberates the operator’s hands, reduces labor intensity, and improves work efficiency.

Roll ejection device

For further safety considerations, we are available to equip the rear roll with an extra safety feature named roll ejection device if required. This device consists of two hydraulic units connected to both ends of the rear roll. It allows a quick-action of opening for the roll once triggering any of the emergency stop switches on the mill. In case the operator’s hand gets stuck in the rolls, this hydraulic device can help in minimizing the injury to the body to the utmost extent.

Rubber Mixing Mill Specifications

Model | R7024-120 | R7024-160 | R7024-200 | R7024-230 | R7024-250 | R7024-X |

Roll diameter | Ф120 mm | Ф160 mm | Ф200 mm | Ф230 mm | Ф250 mm | customized |

Roll length | 350 mm | 350 mm | 520 mm | 520 mm | 630 mm | customized |

Roll Hardness | 50 ~ 60 HRC | |||||

Roll temperature | Ambient temperature ~ 300°C | |||||

Heating mode | Electrical heating / oil heating / steam heating (selectable) | |||||

Temperature accuracy | ±2°C (Electrical heating) ±1°C (Oil heating) | |||||

Cooling mode | Water-cooling (optional) | |||||

Roll speed | 0 ~ 30 RPM | |||||

Friction ratio | Customized fixed value such as 1.17:1, 1.25:1 or adjustable (selectable) | |||||

Roll rev. | Constant speed / Single FM / Double FM (selectable) | |||||

Roll gap | 0.1 ~ 12 mm adjustable | |||||

Control mode | Microprocessor / PLC | |||||

Power supply | 3∮ 380 V, 50 ~ 60 Hz | |||||

AmadeTech Two Roll Mill Features

- Small in size, doesn’t waste raw materials.

- It has high precision, and doesn’t change physical properties by mistake.

- The surface of the roll is hardened, then hard chrome plated, and then mirror ground.

- It can accept raw materials in the form of lumps, pellets, chunks, or powder.

- The distance between the rolls is adjustable to obtain different sheet thicknesses.

- The friction ratio of rolls can be customized.

- Constant speed, single-frequency modulation, and double-frequency modulation for the rolls are available.

- Supports multiple roll heating methods, including electric heating, oil heating, and steam heating (optional).

- The rolls can be cooled by circulating water.

- Roll temperature and speed in real-time are displayed on the screens.

- Using Taiwan brand deceleration motor to bring extremely low noise and excellent durability.

- Teflon is used as the baffle plate, which avoids damaging the roll, removing the heat, and sticking to the pigment.

- Fitted with an automatic oiling and lubrication system for regular and quantitative oiling.

- Configured with multiple emergency stop switches to guarantee the safety of the operator.

Tips on Using the Lab Two Roll Mill

Leave Your Messages Here

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales engineers will respond within one working day.