MIT Tester China Manufacturer and Supplier

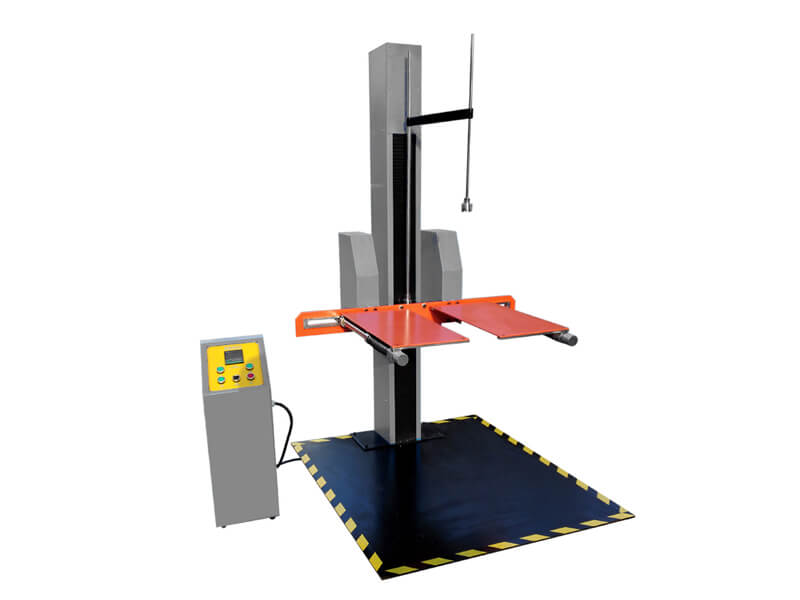

MIT Folding Endurance Tester is a device used to measure the ability of materials to resist repeated bending, folding, and creasing. It can be used to test a variety of materials, including paper, plastic film, aluminum foil, and other flexible sheets, to evaluate their most basic physical properties.

The MIT folding tester is a necessary instrument for determining paper and board folding endurance.

The MIT tester features 2 clamping grips for holding the specimen vertically. The upper grip can be applied with a specified tension, and the lower grip performs a side-to-side oscillating action to complete the test. The newly developed MIT folding tester by AMADETECH is an intelligent and automatic machine. It is equipped with a colorful touch screen to enable you to have a convenient and efficient interaction with the device. The MIT tester is available to automatically record and store the number of folds for multiple test specimens and support on-site printing of test results.

Touch screen version

- If your paper sample thickness is less than 0.25mm, we also have another Schopper-type folding endurance tester to meet your requirements.

- If you want to test the folding resistance of flexible circuit boards, we recommend a special FPC testing machine.

| Product name | MIT Folding Endurance Tester |

| Model | AT-P8007 / AT-P8007D (button model) |

| Specimen | 15 × (150 ~ 200) mm |

| Radius of curvature of the folding surface | R 0.38 mm |

| Folding head width | 19 mm |

| Opening spacing of the folding clamps (mm) | 0 ~ 0.25, 0.25 ~ 0.5, 0.5 ~ 0.75, 0.75 ~ 1.00, 1.02-1.25mm(need to be customized) |

| Folding angle | 135° |

| Folding speed | 175 times / min |

| Adjustable Range of Tension | 4.9 ~ 14.7 N |

| Counter | 0 ~ 999,999 times |

| Operating Language | English / Chinese |

| Print and output | With a modular integrated thermal printer |

| Control method | Colorful touch screen / Digital |

| Optional | Conductive device for testing FPC |

| Power | AC 220 V, 50 Hz, 1 phase or specified |

| Machine dimension | 450 mm (L) × 300 mm (D) × 520 mm (H) |

One end of the paper test piece is mounted in the upper spring-loaded clamp so that the paper is subjected to a specified load. The load is adjustable to offer any desired longitudinal tension on the test piece from a range of at least 4.9 N to 14.7 N. The other end of the test piece is fixed on the opening of the lower folding clamp. The test piece is reciprocating folded by 135° leftward and rightward at a rate of 175 times per minute until the rupture of the test piece occurs.

- TAPPI-T511

- ASTM-D2176

- JIS-P8115

- GB/T2679-5

- ISO 5626, etc.

Features of AT-P8007 MIT Folding Endurance Tester

- The MIT tester can automatically record the number of double folds of the tested sample.

- The control system is able to make the folding head return automatically after each test. No manual operation is required.

- It possesses powerful data processing functions. Not only the number of double folds of a single sample test is recorded, but also the test data of multiple samples in the same group can be counted, such as the maximum, minimum, and average values of the folding of the same group of samples.

- It can directly print the test results on-site.

Requst a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amade Tech sales engineers will respond within one working day.