Cobb Sizing Tester Manufacturer and Supplier

Cobb Tester is also called the water absorption tester, which is intended for determining the water absorption capacity of sized paper, paperboard, and corrugated fibreboard under specified conditions. It is not suitable for bibulous papers.

The machine allows you to measure the quantity of water that can be absorbed by the surface of paper or board in a specified time. The increase in mass of the specimen due to the absorption of water is used to determine the water absorptiveness.

The Cobb test is important in packaging and paper industry. If your specimens are porous papers or unsized papers having a relatively high water absorptiveness, performing the water absorption test with our AT-P8038 Klemm Capillary Rise Tester is more suitable.

Test Principle

A weighed test specimen is firmly clamped between the base plate and the edge of the cylinder, ensuring that the side to be tested will be in contact with the water. The specified volume of water is poured into the cylinder rapidly, and timing is started immediately. Any leakage of water during the test is not allowed. The test specimen is removed once the specified time of directly contacting water is achieved and then placed between 2 sheets of blotting paper to remove the excess water using a metal roller with two rollings while the selected test duration is up. The wetted test specimen is weighed again to calculate the mass difference before and after the test. The value determines the water absorptiveness.

| Model | AT-P8006A/B |

| Metal cylinder | Inner diameter: 112.8mm Thickness: 6mm Height: 25mm |

| Metal roller | Width: 200 mm, diameter: 90 mm, mass: 10 kg |

| Test area | 100 cm2 |

| Weight | 13 kg |

| Overall dimension | 200 x 300 x 200 mm |

- TAPPI-T441

- ISO 535

- JIS-P8140

- EN 20535

- GB/T 1540

- Made of stainless steel and rigid metal with excellent rust and corrosion resistance.

- It is user-friendly, without complex operation.

- Conforms to various test standards.

- Highly cost-effective.

Types of the Cobb Sizing Testers Available from AMADETECH

AMADETECH can provide two types of cooper testers, one is a flat pressure type, and the other is a flip type. You can use either, as they both meet the relevant standards.

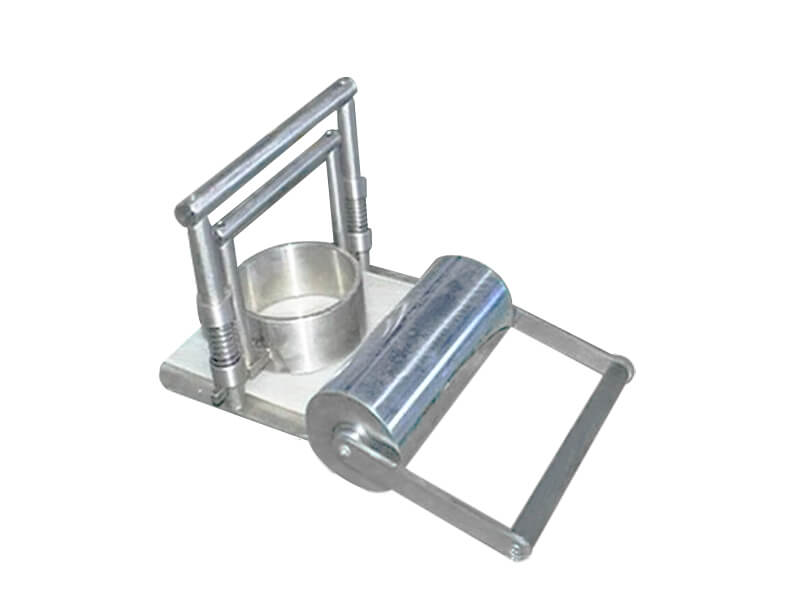

Flat Pressure Type Cobb Sizing Tester (AT-P8006A)

Our Cobb sizing tester features a one-piece stainless steel base plate and a stand, with a rigid metal cylinder of (112.8±0.2) mm in internal diameter, corresponding to a test area of 100 cm2. The edge of the metal cylinder in contact with the test specimen is flat and machined smooth to prevent damage to the specimen. The cylinder edge is capable of clamping the specimen firmly in actual service under a special mechanism by means of a pair of powerful springs on each side. A piece of rubber mat is available to be placed on the rigid base plate to prevent water leakage during the test. The stand with a handle allows you to hold upward firmly and raise the cylinder fast to achieve rapid removal of the specimen, saving some time compared to traditional screw removal.

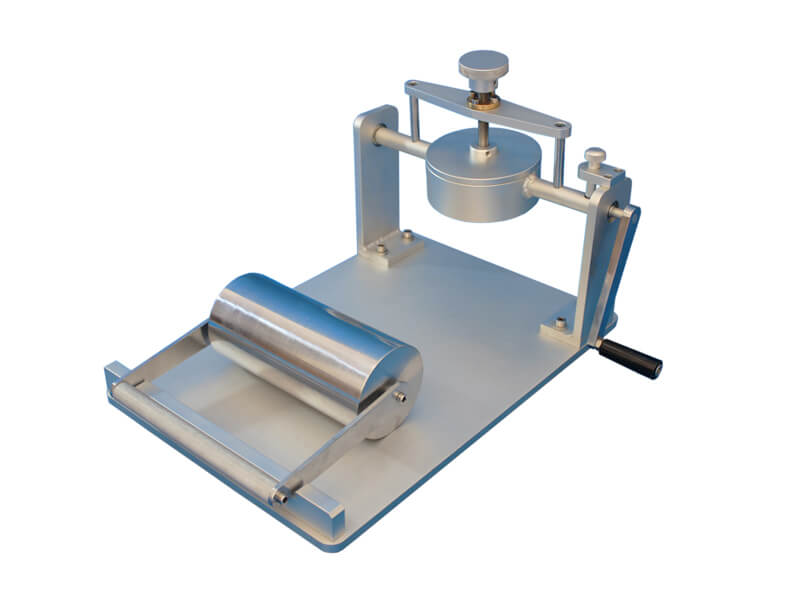

Flip Type Cobb Sizing Tester (AT-P8006B)

The flip-type Cobb sizing tester appears in the GB/T 1540 standard. Its function is the same as the flat pressure type, but the instrument structure and operation method differ. It is characterized with a cylindrical stainless steel bowl that is manually reversible. Before mounting the sample, you need to pour an appropriate amount of water into it, then place the sample and lid on the mouth of the bowl in sequence and clamp the sample by tightening the screw. When the timing starts, you are required to simultaneously turn the upside of the bowl down manually and quickly to allow even and sufficient contact between the water and the test side of the specimen. After a period of the prescribed time, you need to invert the bowl again and place the wetted specimen between two sheets of blotting paper with a roller to remove excess water to reweigh.

Flip-type Cobb tester

Cobb Test Procedure (With the Flip-type Cobb Tester)

- Use a Cobb test sample cutter to cut out at least 10 pieces of circular samples with a diameter of 125 mm.

- Select a test piece and weigh it using a digital balance to the nearest 0.001 g and record it as M1.

- Fill the graduated cylinder with 100 ml of distilled water and pour it into the metal bowl.

- Place the weighed test piece on the ring of the metal cylinder, ensuring the side to be tested is downward, and then cover the test piece with the lid (a rubber mat is added between the test piece and the lid if necessary), as last, clamp the test piece firmly by turning the retaining screw to prevent leakage.

- Turn the crank handle to control the bowl direction by 180 degrees to allow the water to fully come in contact with the test piece and simultaneously start the stopwatch.

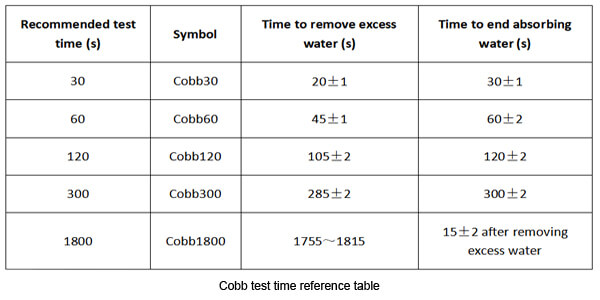

- Select an appropriate test time consistent with your test piece water absorptiveness from the below table, and invert the bowl by 180 degrees 10 ~ 15 seconds before the exposure time ends.

- Loose the screw and remove the test piece. Place the test piece on a sheet of blotting paper, ensuring that the side to be tested is upward, and place a second sheet of blotting paper on top of the test piece.

- Use the roller to roll on the blotting paper twice (once forward and once backwards) without applying any additional pressure.

- Take out the test piece to weigh again nearest to 0.001 g and record it as M2.

- Calculate the Cobb value of a single test piece. (Refer to the formula in the following section)

- Repeat the above steps for the rest test pieces (At least five tests are required to be carried out on each face of the sample paper or board). Then calculate the average of each face of the sample as the final Cobb value.

Cobb Test Formula

The Cobb value calculation formula is as follows:

C = (M2 – M1) x 100

Where,

C is the water absorptiveness (increase in mass of water absorbed in a specified time by 1 m2)

M2 is the mass of the test piece weighed out after water absorption

M1 is the mass of the test piece weighed out before water absorption

Note:

- If the Cobb value is high, it means the base material has a strong ability to absorb and retain moisture.

- If the COBB value is low, it means the substrate can resist penetration and retention of moisture.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amade Tech sales engineers will respond within one working day.