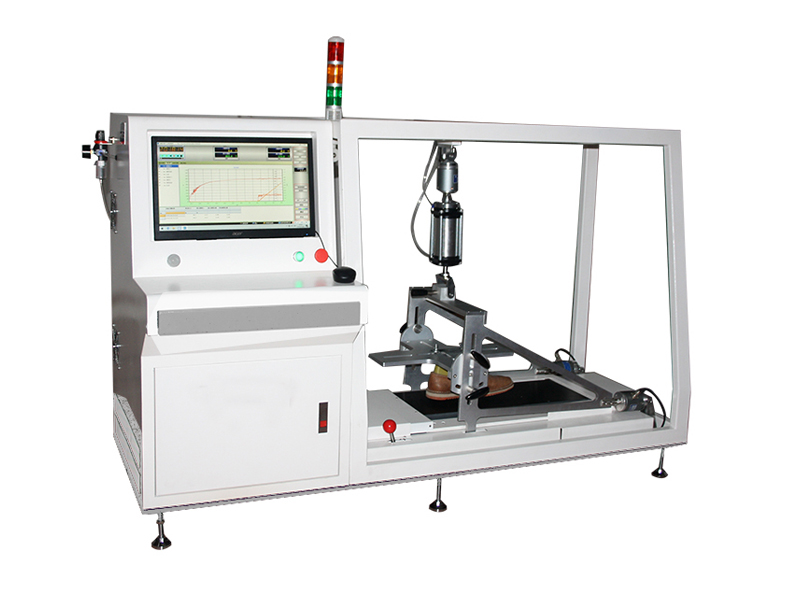

SATRA TM144 Computerized Footwear Slip Resistance Testing Machine China Manufacturer

Footwear Slip Resistance Tester is used to determine the anti-slip performance of footwear by measuring the coefficient of friction between footwear outsoles and flooring surfaces in a dynamic manner under specified conditions.

It is suitable for testing different types of footwear, outsole units, heel top pieces, sheet soling materials, and most types of floorings. But footwear containing spikes, metal studs or similar are not included.

Our slip resistance tester has a rigid horizontal surface mount to hold different types of test floors, such as steel floors, ceramic tile floors, concrete floors, wood floors, etc., whose surfaces are allowed to be dry or wet with contaminant during the test based on requirements. You are required to lower the specimen mounted on the shoemaking last/mechanical foot or attached to the flat mounting surface onto the flooring surface.

It supports different test modes, including heel mode, forepart mode, top piece/material mode, etc., depending on the specimen contact position and the direction of the acting force. Rigid wedges of angles 5° and 7° are available to assist in adjusting the contact angle of the specimen when required. The test floor is able to move horizontally at a specified speed under control relative to the specimen bearing a prescribed normal force for initiating the sliding movement.

Our slip resistance tester is a computer-aided test facility. It is equipped with a full set of computer hardware and software, which is linked with the corresponding driving, measurement, and control system. It enables a series of instructions regarding the magnitude and timing of vertical force application, horizontal displacement control, data acquisition, and measurement to be transmitted and executed accurately. The software interface is concise and easy to use.

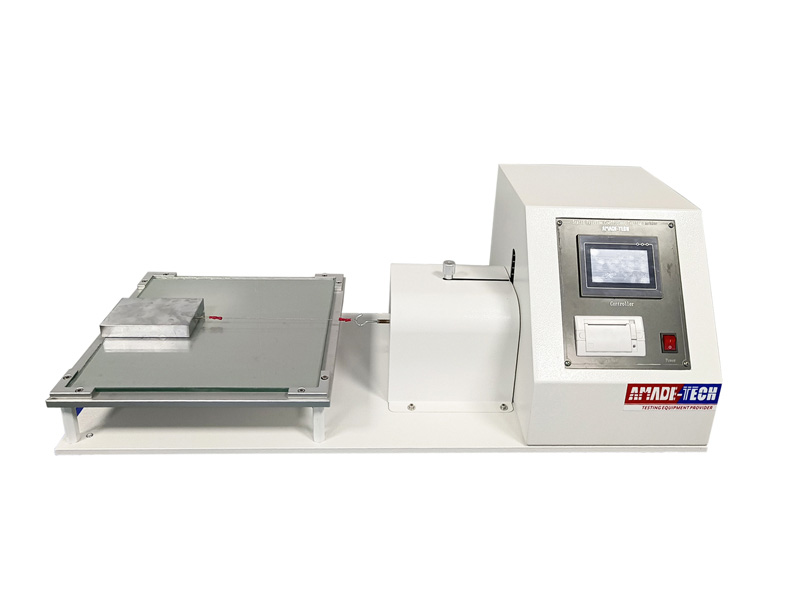

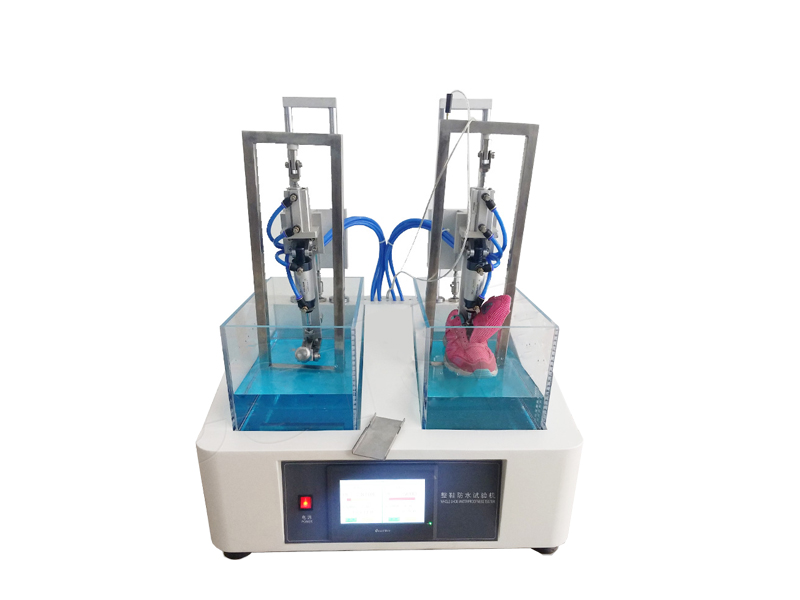

More Slip Resistance Testers

Test Principle

A prepared footwear or footwear material specimen is lowered and positioned to make contact with a flooring surface at a specified angle (if required). A predefined normal force is applied to the specimen, and the surface is moved horizontally relative to the specimen at a given speed, during which both the friction force and vertical force are measured by the corresponding mechanism. And the dynamic coefficient of friction is calculated.

Test Standards

- BS EN ISO 13287

- SATRA TM144

- ASTM F 2913

Main Technical Parameters

| Model | AT-F3028 |

| Normal force | 0 ~ 1000 N, adjustable |

| Horizontal sliding force | 0 ~ 1000 N |

| Test speed | (0 ~ 1.5±10%) m/s, adjustable |

| Surface Move stroke | 0 ~ 200 mm |

| Static contact time | 0 ~ 5 s |

| Normal force sensor | Capacity 1 kN (1 pc, disk type, from Japan NTS) |

| Normal force accuracy | ± 0.5% |

| Horizontal force sensor | Capacity 1 kN (2 pcs, disk type, from Japan NTS) |

| Horizontal force accuracy | ± 0.5% |

| Vertical force control time | 0 ~ set value, less than 0.2 s |

| Displacement sensor accuracy | 0.001 mm |

| Operating language | English/Chinese |

| Weight | 300 kg |

| Dimensions | 168 mm (L) x 70 mm (D) x 100 mm (H) |

| Power supply | AC 220V 50Hz 1500W or Specified |

Footwear Slip Resistance Tester Features

- Made of rigid steel and aluminum alloy.

- Equipped with a planetary reducer: the reduction ratio is 1:15, and the operation is low noise.

- Adopts precision linear guide rail.

- Fitted with a high-end brake clutch.

- The pressurization system is controlled by a Japanese SMC proportional valve, which is automatically pressurized after the computer setting.

- High-speed acquisition system and special test software.

- The system responds quickly, and the control deviation is small.

- Built-in EN 13287, SATRM 144, ASTM F2913, GB/T3903.6, and other test methods, which can be called directly.

- The test result contains a curve graphic of the test process.

- The test result allows to be printed out.

- Equipped with leakage protection, pressurized overload protection, air buffer stroke limit protection, emergency stop switch, and other protection devices.

- Comes with a pneumatic spray gun as the cleaning device.

Leave Your Message Here

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.