IPX5 / IPX6 / IPX6K Waterproof Test Set-up China Manufacturer

The IPX5/6/6K Water Jetting Test Chamber is engineered to project high-pressure water jets against an enclosure from all directions to verify compliance with specific ingress protection (IP) ratings.

This equipment is essential for evaluating the waterproof integrity of outdoor lighting, signaling equipment, automotive lamp housings, and other critical electronic components.

Integrated Design and Construction

AmadeTech’s box-type equipment features an integrated, one-piece test chamber constructed from premium 304 stainless steel for superior corrosion resistance and longevity.

At the base of the chamber, a motorized turntable secures the specimen, rotating automatically to ensure the sample is exposed to water jets uniformly from every angle. The inner chamber is equipped with a waterproof power socket(optional), allowing for “power-on” testing if required.

Inner chamber

A precision-engineered port (available in circular or rectangular configurations) is located on the side of the chamber, connecting to a 2.5-meter water conduit. This setup introduces the external jet spray into the chamber to act directly on the sample. To promote efficiency and sustainability, a collection tank at the bottom of the chamber captures the water, which is then filtered and pumped back to the nozzle through a closed-loop recycling system.

Dia. 6.3 mm & 12.5 mm nozzles

Precision Nozzles for Versatile Testing

The water jet is delivered via the nozzle, precision-machined from high-grade metal. To meet diverse testing standards, AmadeTech provides two specialized nozzles with every machine:

- 3 mm Diameter Nozzle: Specifically designed for IPX5 and IPX6K testing.

- 5 mm Diameter Nozzle: Designed for high-flow IPX6 testing.

Users can switch between these nozzles quickly on the control panel to meet various testing requirements. Furthermore, the equipment offers flexible motion control: users can opt for a fixed nozzle position or enable an automated up-and-down oscillation, ensuring the specimen is thoroughly sprayed from all required directions according to practical testing needs.

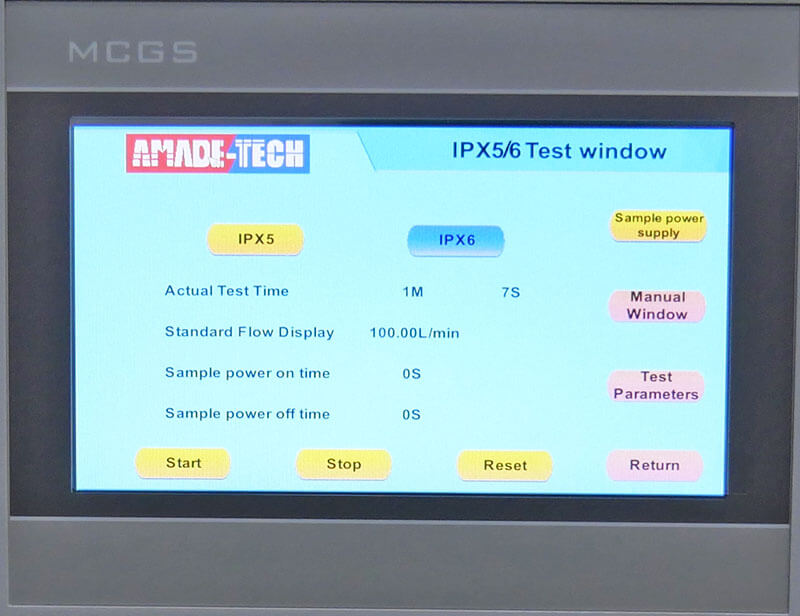

Advanced PLC Control and Intuitive HMI

For streamlined operation, the system is equipped with a 7-inch PLC-driven touchscreen interface. The user-friendly HMI (Human-Machine Interface) allows operators to simply select the desired IP rating and test duration. Once initiated, the equipment executes the programmed test protocol automatically, enabling unattended operation. The screen displays real-time data and safety alerts, ensuring comprehensive monitoring and efficient human-machine interaction throughout the process.

Touch screen

Custom All-in-One IP Test Chambers

Maximize your lab space and reduce equipment costs with our Integrated Ingress Protection Systems. AmadeTech can engineer a single, high-performance chamber that combines multiple testing standards—including IPX1, IPX2, IPX3, IPX4, IPX5, IPX6, and IPX9. Instead of purchasing and maintaining separate machines, you can perform all your waterproof verification in one versatile unit.

Whether you need a unique chamber size or specialized functionality, AmadeTech is ready to help. Contact us today to receive a customized quote and technical solution designed specifically for your product requirements.

Combined test chamber

In addition to self-contained chambers, AmadeTech offers open-type test systems for maximum flexibility. This enclosure-free configuration features a split design where the nozzle and turntable are separated from the central control unit and water reservoir. This layout removes space constraints, making it ideal for large-scale specimens. While this setup requires a dedicated waterproof site with integrated drainage, it provides the operator with the freedom to manually adjust spray angles and distances, ensuring total coverage for complex geometries.

| Test Item | IPX5 | IPX6 | IPX6K |

| Nozzle internal diameter | 6.3 mm | 12.5 mm | 6.3 mm |

| Water pressure | Approx. 30 kPa | Approx. 100 kPa | Approx. 1000 kPa |

| Water flow rate | 12.5 l/min ± 5% | 100 l/min ± 5% | 75 l/min ± 5% |

| Exposure time | 1 min/m2, at least 3 min | 1 min/m2, at least 3 min | at least 3 min |

| Distance from nozzle to enclosure surface | 2.5 ~ 3 m | 2.5 ~ 3 m | 2.5 ~ 3 m |

- IEC 60529

- ISO 20653

- DIN 40050-9, etc

Main Technical Specifications

Model | AT-1005C | AT-1005C-600 | AT-1005C-800 | AT-1005C-1000 | AT-1005C-1180 |

Equipment type | Open-type | Box-type with an enclosed chamber | |||

inside chamber dimensions | / | (W) 600 x (D) 600 x (H) 600 mm | (W) 800 x (D) 800 x (H) 800 mm | (W) 1000 x (D) 1000 x (H) 1000 mm | (W) 1180 x (D) 1180 x (H) 1180 mm |

Overall dimensions | (W) 1100 x (D) 900 x (H) 1300 mm | (W) 3550 x (D) 1050 x (H) 1600 mm | (W) 3550 x (D) 1050 x (H) 1600 mm | (W) 4050 x (D) 1250 x (H) 1850 mm | (W) 4350 x (D) 1400 x (H) 1900 mm |

Turntable diameter | Dia. 600 mm | Dia. 400 mm | Dia. 600 mm | Dia. 600 mm | Dia. 800 mm |

Turntable height | Fixed | ||||

Nozzle opening size | Dia. 6.3 mm (IPX5 & IPX6K), Dia. 12.5 mm (IPX6) | ||||

Water flow and pressure required | IPX5: 12.5 L/min ± 5%, pressure appr. 30 kPa IPX6: 100 L/min ± 5%, pressure appr. 100 kPa IPX6K: 75 L/min ± 5%, pressure appr. 1000 kPa | ||||

Water jetting distance | 2.5 ~ 3 meters | ||||

Control mode | PLC + 7-inch touch screen | ||||

Feature | Allows energized samples during the test | ||||

IPIPX5 IPX6 Water Jetting Test Equipment Features

- Customizable Chamber Sizes: Our IPX5/6/6K chambers are available in various sizes, with custom dimensions available to accommodate your unique specimen requirements.

- Corrosion-Resistant 304 Stainless Steel: Built with a premium 304 stainless steel interior, ensuring long-term durability in high-humidity testing environments.

- Sustainable Water Recycling: Save on resources with our closed-loop water recycling system, featuring an internal filter to protect the pump and nozzles from debris.

- Smart PLC Touchscreen Interface: Easily configure test ratings and durations via the 7-inch touchscreen. Monitor real-time data and system status at a glance.

- 360° Automated Testing: The automatic rotating turntable ensures that the high-pressure water jets reach every angle of your product for reliable results.

- Support for Live Electrical Samples: Safely conduct functional tests while the product is powered on, thanks to our integrated internal power supply system (optional).

- Superior Visibility: The large, transparent observation window allows engineers to track the exact moment of ingress or failure without interrupting the test.

- Advanced Safety Features: Engineered with built-in protection against electrical leakage, short-circuits, and overloads for a worry-free testing environment.

- Portable Laboratory Solution: Equipped with high-quality castors, making it easy to move the equipment throughout your facility as needed.

Frequently Asked Questions (FAQs)

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales specialists will respond within one working day.