AT-R7007 Rubber Low-Temperature Brittleness Tester China Manufacturer

Brittleness Temperature Tester is intended to measure the brittleness temperature of vulcanized rubber, which is the lowest temperature at which none of a set of specimens fractures due to low-temperature embrittlement when tested under the specified conditions.

The low-temperature brittleness tester can be used to make comparative identification of functional performance for the non-rigid plastic and other elastic materials under the low-temperature condition and measure the pros and cons of low-temperature properties of different rubber materials and compound rubbers with different formulas. Therefore, the brittleness temperature tester is one of the vital rubber instruments in the quality inspection of scientific research and controlling the production process.

This testing machine comprises a refrigeration system, temperature control device, temperature-measuring device, heat-transfer medium, cooling bath, automatic alarm device, etc.

After turning on the refrigerating switch, the compressor starts working to enter into the refrigerating state. When it is close to the set temperature, the heating device in the cooling tank starts to provide heat in proportion to balance the excess cold produced by the refrigeration system to achieve the purpose of constant temperature. Stirring can continuously circulate the cooling medium in the cooling bath to ensure the uniformity of temperature.

INQUIRE

Test Principle

A test piece is clamped in the clamp and immersed into the constant low-temperature container with the freezing medium to precool for 5 minutes. A striking edge is delivered to impact the specimen at the linear velocity of 2 ± 0.2 m / s. The operator examines each test piece to determine whether or not it has failed. According to different results, the operator lowers or raises the temperature of the cooling medium and continues the test until the brittleness temperature of the test sample is measured.

Test Standards

ISO 812 Rubber, vulcanized or thermoplastic determination of low temperature brittleness

ISO 974 Plastics determination of the brittleness temperature by impact

ASTM D746 Brittleness temperature of plastics and elastomers by impact

JIS K6261 Rubber vulcanized or thermoplastic determination of low temperature properties

Main Technical Parameters

| Model | AT-R7007 |

| Temperature Range | RT ~ 70℃ (optional) |

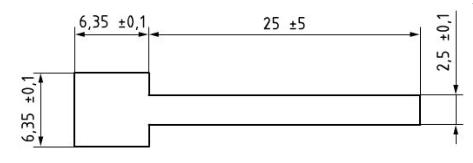

| Specimen | 6 mm (W), L40 mm (L), thickness: 2.0 ± 0.2 mm (Type A)

Type B (T-shape)

|

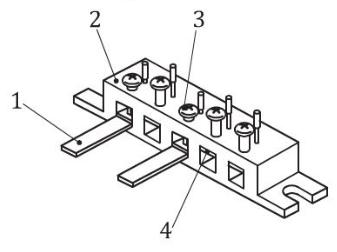

| Test Piece Clamp | 5 pcs / set, 4 sets in total

|

| Striking Edge | Radius: 1.6 ± 0.1 mm, Clearance from striker to the clamp at impact: 6.4 ± 0.3 mm, Distance from Point of impact to clamp: 8 ± 0.3 mm

Clamping length of the test clamp: 6.8 ± 0.3 mm |

| Striking Speed | 2.0 ± 0.2 m / s |

| Refrigerating Method | Refrigerator |

| Heat-transfer Medium | Ethanol or other non-freezing liquid |

| Power Supply | 1 Phase, AC 220 V, 50 Hz |

| Air Supply | 0.5 mPa or more |

Rubber Embrittlement Tester Features

- It owns the novel design, particular structure, advanced technology, reliable performance, and high-grade automation.

- Compatible with various liquid mediums.

- Capable of keeping the temperature of the medium to within ± 1℃.

- The new type of compression refrigeration is applied to ensure smooth and accurate cooling.

- A digital screen is equipped to show the temperature in real-time.

- A stirrer moves the liquid to ensure a uniform temperature in the liquid.

- It can test the brittleness temperature and status in the low temperature of vulcanizates in different formulas.

- Complies with various international standards such as ISO, GB/T, ASTM, JIS, etc.

Low Temperature Brittleness Test Procedure

- Power on and turn on the machine, indicating lights for temperature control, and the timer will be on.

- Pour the cooling medium into the medium bath to ensure approximately 25 mm depth or more liquid over the test piece(s).

- Set and bring the bath to a temperature less than the expected lowest temperature of non-failure.

- Immerse the specimen clamp in the bath to precool it.

- Mount the test pieces in the holder, then immerse them for 5 min at the test temperature. The temperature fluctuation of the cooling medium can’t exceed ± 1℃.

- After pulling the self-locking handle of the impact hammer, the impact hammer will fall freely under the action of gravity and make an impact action on the sample.

- Remove the test piece from the holder to examine whether or not any one of the specified failures like the crack, fissure, or hole occurs. Bend it at a place where a specimen has not completely separately to an angle of 90° in the same direction as the bend caused the impact. Then, inspect it for cracks in the bending area.

- Repeat the test at each of a series of successively higher temperature 10°apart, using a new set of test pieces at each temperature until no failure is observed. Then, decrease the temperature to the highest value at which a failure was obtained and perform tests at temperatures increasing at 2℃ intervals to determine the temperature at which no failure is obtained. This is the brittleness temperature.

The above is just for a reference. Please strictly follow the procedure of the applied standard to carry out the test when you get this testing machine.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.