When it comes to“UN38.3”, most people feel strange with this noun because they have little chance to hear it.

UN/DOT 38.3 is familiar to the manufacturers of lithium batteries and electronic products, shipping agents, airlines staff, customs officers, etc., because people in these industries definitely need to understand and be exposed to many different types of cell and battery in their work.

If you want to learn more about the UN38.3 test, please read the following with me.

Who Wrote UN38.3

UN38.3 was written by the United Nations Committee of Experts on the Transport of Dangerous Goods, and usually, its version is updated every two natural years.

What’s the Reason for Writing UN38.3

Look at your camera, phone, laptop, and Tesla car, What they have in common is that they are driven by lithium batteries.

Half a century has passed since the first lithium-ion battery was born in 1970, and lithium-ion batteries are playing an increasingly important role in our lives.

Lithium batteries have brought more and more convenience and possibilities to our lives. They are featured with long service life, high energy density, high output voltage, small self-discharge, high charging efficiency and strong adaptability to high temperature and ultra-low temperature, widely used in various industries from medical products to consumer electronics, and from industrial finishes to transportation tools.

But just like a coin has two sides, everything has advantages and disadvantages, and lithium batteries have no exception. While enjoying the excellent performance, we should also tolerate the weaknesses.

The most apparent shortcoming of lithium batteries is the relatively poor safety performance. Sometimes, this property brings hazards to people’s daily life, especially when the lithium batteries or the products with lithium batteries are transported by air.

Suppose an accident happens to the batteries carried by plane, which will be fatal. We know that the aircraft can not have the slightest risk and danger of fire and explosion while flying at a high altitude.

In order to solve this problem, there must be a globally recognized test standard to test these batteries to be shipped, so the UN38.3 was born.

What’s the UN38.3

UN38.3 is a test standard, short for “UN Manual of Tests and Criteria Part III, Subsection 38.3”.

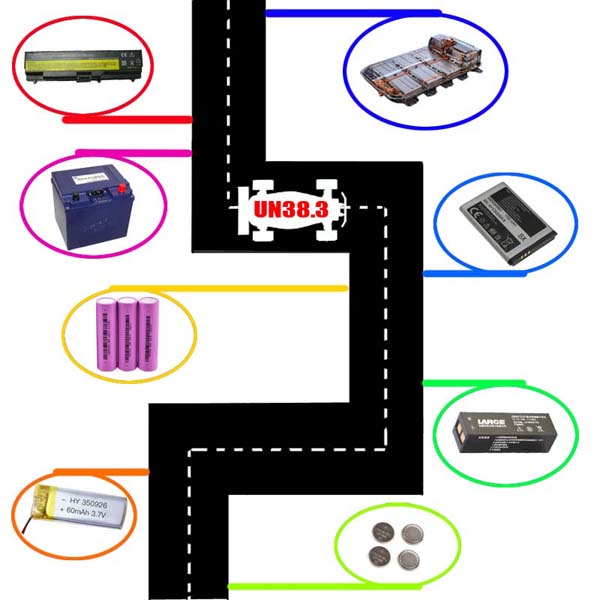

It is specially formulated for the safe transport of lithium metal and lithium-ion cells and batteries, covering eight different test items, designed to simulate air/sea/land transportation environments and possibly dangerous situations.

Why Conduct the UN38.3 Test

The test object of UN38.3 is Lithium cells and Lithium batteries, which are mainly composed of negative electrode materials, electrolyte and positive electrode materials. The chemical activity of the cathode material graphite in the charging state is close to that of lithium metal, and the SEI film on the surface decomposes at high temperature. The lithium ions embedded in the graphite react with electrolyte and binder polyvinylidene fluoride (PVDF) to emit a large amount of heat.

From this point of view, lithium-ion batteries do have a certain risk. Especially when in abuse or subjected to external factors, safety issues will be more prominent.

Lithium batteries are widely used in mobile communication equipment, electronic digital products, power products, medical and security products. After these products are produced in the factory, if they want to circulate normally in the country and the world, they must be transported by land, sea, and air.

As a kind of dangerous goods, lithium batteries are uncontrollable due to their active chemical properties and changes in the environment during transportation, plus some unexpected accidents during transportation. If the quality of some lithium batteries is not up to standard and they are also loaded into the cargo compartment, it is very likely that fire and explosion will occur.

Airlines have become more and more stringent in monitoring the transportation of lithium batteries and goods containing lithium batteries. To avoid accidents during lithium battery transportation, each lithium battery cell or lithium battery must be certified to meet the UN38.3 test requirements.

Moreover, the Civil Aviation Administration also stipulates that airlines and airport cargo collection and transportation departments should scrutinize various transportation documents of lithium batteries. The most important thing is the UN38.3 safety test report for each type of lithium battery. If this test report can’t be provided, the transportation of lithium batteries is prohibited.

Lithium-ion batteries have repeatedly caught fire during transportation. Below is just one of the case. At 2 pm on January 8, 2017, an air cargo container suspected of carrying lithium batteries caught fire on the parking apron of Hong Kong International Airport, emitting a lot of thick smoke. The airport firefighter rushed to the scene about 4 minutes after receiving the alarm, and the fire is put out after about 25 minutes. Fortunately, the cargo has not been loaded on the plane. Otherwise, It would be an unimaginable disaster. The airline penalized the consignor involved, and the consignor has been blacklisted by the airline.

What Makes the Lithium Battery Unsafe

Generally speaking, the safety troubles of lithium-ion battery show up as burning and even explosion.

(1) The root cause of these problems is the thermal runaway inside the battery. Lithium-ion batteries create heat throughout discharging as well as charging. Suppose the heat produced surpasses the battery’s heat dissipation capacity. In that case, the lithium-ion battery will undoubtedly overheat, and the battery material will certainly break down the SEI film, resulting in electrolyte disintegration, electrode decomposition.

(2) Some external factors such as short circuit, overcharge, crushing, nail penetration, etc., also can cause security problems.

♦♦ The short circuit causes most lithium battery fires and explosions. The internal short circuit of the battery cell will cause a large current discharge and generate a lot of heat to burn the diaphragm and result in a more extraordinary short-circuit phenomenon, which will cause the electrolyte to decompose into gas. If the internal pressure is too high, the battery cell will explode. The Reason for the internal short circuit of the battery may be the design reason or quality of the battery materials, or it may be caused by vibration, impact, impact, extrusion during transportation.

♦♦ The external short circuit may be caused by the wrong connection of the positive and negative electrodes. Due to the external short circuit, the battery discharge current is considerable, which will cause the battery core to heat up. The high temperature will shrink or ultimately damage the diaphragm inside the battery core, causing an internal short circuit and thus an explosion.

♦♦ When the battery is overcharged, the excessive release of lithium in the positive electrode will change the positive electrode structure. If too much lithium is released, it is easy to cause lithium deposition on the surface of the negative electrode. Moreover, when the voltage reaches 4.5V or more, The electrolyte will decompose to produce a large amount of gas. All the above phenomena may cause an explosion.

What Types of Battery Can Be Tested by the UN38.3

The Lithium-ion battery/cell

Lithium-ion battery generally uses lithium alloy metal oxide as the anode material, graphite as the cathode material, and uses non-aqueous electrolyte, which is rechargeable.

In the market, the primary testing target of UN38.3 standard is a lithium-ion battery, which mainly includes the following two categories according to the use:

♦♦ The first is the lithium batteries used on digital products, including mobile phone, laptop, tablets, bluetooth headset, digital camera, portable bank power, and so on.

♦♦ The second is the power lithium batteries, which are utilized on electric vehicles by automobile companies like TESLA and BYD. Electric bicycles, unmanned aerial vehicles (UAVS) and other high-power products also use power lithium batteries, whose requirement for instantaneous current is very high. The batteries applied to digital products can’t satisfy the large rapid current, so the power lithium battery is also called a high-magnification battery.

The Lithium Metal battery/cell

Lithium metal battery generally use manganese dioxide as the anode material, lithium metal or its alloy metal as the cathode material, and utilizes non-aqueous electrolyte solution, which is non-rechargeable.

Although lithium-metal batteries have a high energy density, which can theoretically reach 3,860 watts/kg, it is not stable and can’t be recharged, so it can’t be used as a battery for repeated use.

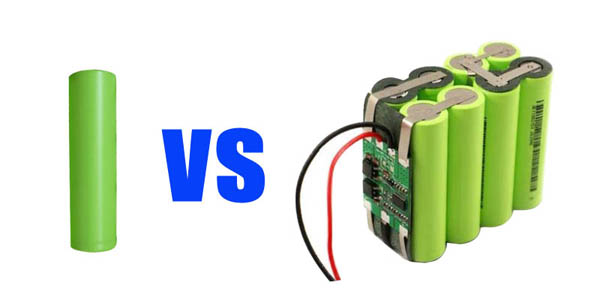

What’s the Difference Between the Lithium Cell and the Lithium Battery

The lithium cell is mainly composed of positive electrode material, negative electrode material, electrolyte, diaphragm and shell.

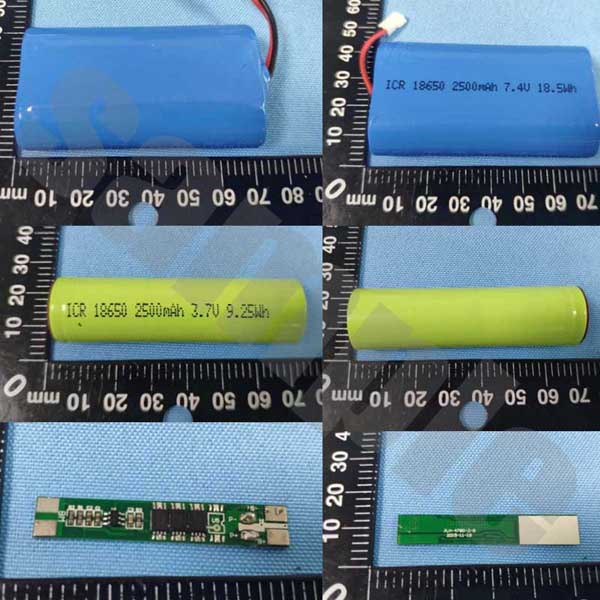

Relatively speaking, the size of a cell is smaller than that of a battery. The cell is a semi-product, which can’t be used individually, but there is also exception: sometimes, one single lithium cell is directly packaged into a battery. The most common type is the 18650 lithium battery, but the precondition is that its discharge circuit has a protection mechanism. If without protection, user needs to pay attention to safety during the use of such a battery .

Lithium battery is mainly composed of two parts: cell and protection board PCM (It is generally called battery management system BMS in power battery field), the protection board is mainly composed of protection chip (or management chip), MOS tube, resistor, capacitor and PCB board, etc.

In short, the battery cell is equivalent to the heart of the lithium battery, and the battery management system is equal to the brain of the lithium battery.

Why Is the UN38.3 Test Especially Necessary for Shipping by Sea and Air

Shipping by sea is characterized by low freight but long transportation time. During the transportation process, lithium batteries/cells or products with lithium batteries stuffed in the container are stacked on the moist deck for a long time, withstanding the high temperature and low temperature. Besides, there is a risk of collision when batteries are loaded on board and unloaded from the ship.

Although air transportation is fast, the air pressure is lower than that on the ground when the aircraft flies in the stratosphere. The batteries are prone to cause short circuit in the environment of sometimes high temperature and occasionally low temperature. The turbulence in the air may cause the batteries to collide with each other, and the vibration caused by takeoff and landing will also have a particularly negative impact on the batteries.

Several unstable factors can lead to abnormalities in the chemical content of the battery, further resulting in danger. It is impossible to ban all the trade and transportation of batteries and electronic products among all countries in the world. Sea transportation and air transportation are two core kinds of transportation modes that are impossible to replace. How to deal with that?

Don’t worry, the content of UN38.3 has taken these factors into account for you. The tests items of the UN38.3 are designed to simulate all these risky scenarios. By placing the battery in these scenes, we can know in advance whether the battery can safely adapt to these conditions.

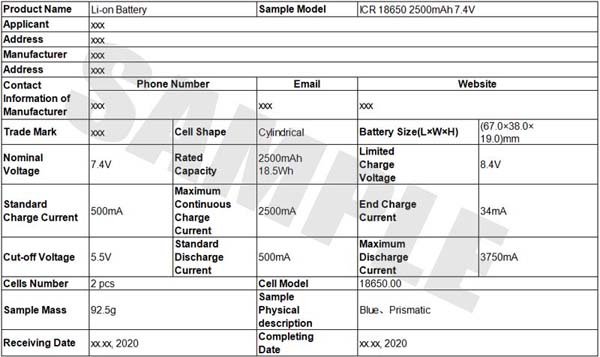

What’s the UN38.3 Test Report

The UN38.3 test report is a formal certificate used to prove that the target battery has been subjected to all required test projects from T1 to T8 of UN38.3 standard.

In China, It is the mandatory document that has to be presented to relevant authorities when shipping lithium batteries or goods containing lithium batteries by aeroplane or boat.

Generally, it is made up of 9 parts as below:

I. Sample Description

It covers comprehensive information, including sample name, model, applicant, manufacturer, normal voltage, rated capacity, limited Charge voltage, Charge current, Maximum continuous charge current, end charge current, cut-off voltage, maximum discharge current, etc.

II.Standard

UNITED NATIONS “Recommendations on transport of dangerous goods, manual of tests and criteria(ST/SG/AC. 10/11/Rev.6/Amend.1 Section 38.3)

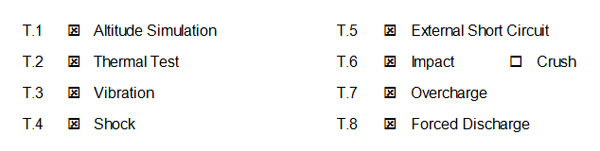

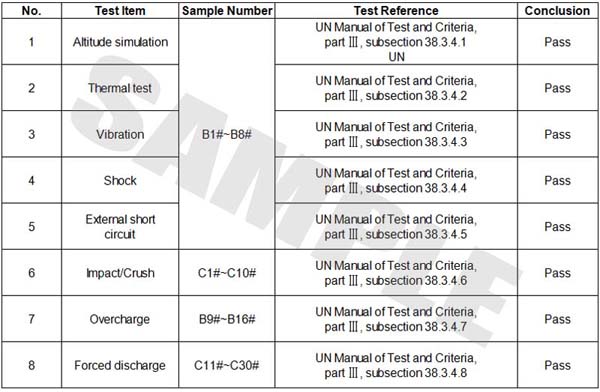

III.Test Item

Eight test items in total are listed here, and please note that Impact Test and Forced Discharged test are applicable to lithium cells rather than lithium batteries.

IV.Test Method and Requirement

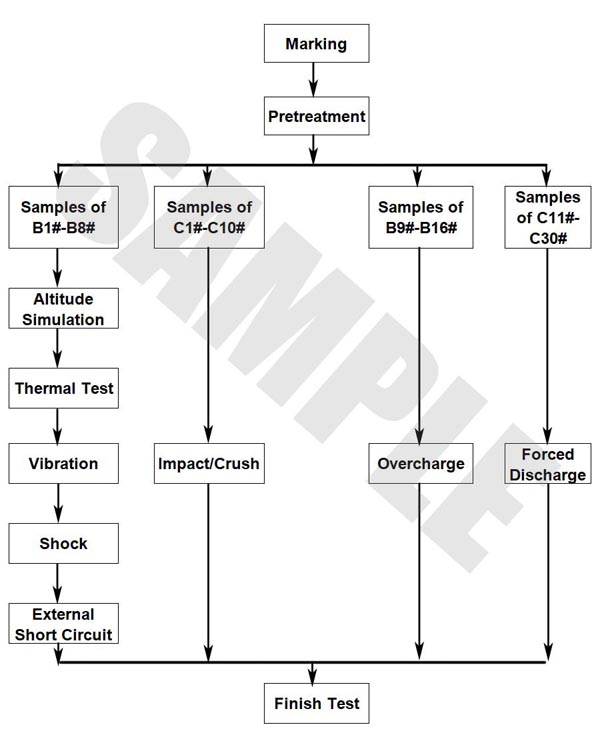

♦♦ Tests from T.1 to T.5 shall be conducted in sequence on the same cell or battery.

♦♦ Test T.6 and T.8 shall be carried out using not otherwise tested cells.

♦♦ Test T.7 may be conducted using undamaged batteries previously used in Test T.1 to T.5 for purposes of testing on cycled batteries.

Batteries of B1# to B4#, B9#-B12# are full charged after one cycle;

Batteries of B5# to B8#, B13#-B16# are full charged after 25 cycles;

Component cells of C1# to C5# are 50% charged after one cycle;

Component cells of C6# to C10# are 50% charged after 25 cycles;

Component cells of C11# to C20# are full discharged after one cycle;

Component cells of C21# to C30# are full discharged after 25 cycles;

Test environment condition: ambient temperature: 15-25℃, ambient humidity: 40-70%.

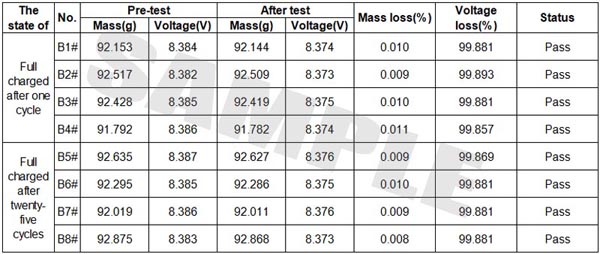

♥♥ In order to quantify the mass loss, the following equation is provided:

Mass loss(%)=(M1-M2)/M1*100

Where

M1 is the mass before the test and

M2 is the mass after the test.

When mass loss doesn’t exceed the value in the table now, it shall be considered “no mass loss”.

More details on Test Methods and requirements covering T.1 to T.8 are also listed here.

V. Test Procedure

VI. Main Test Apparatus

This part includes all names of apparatus used during the test. The core testing equipment will be described in the following detail of this article.

VII. Test Data

The required test data from T.1 – T.8 are listed respectively, the picture as below is the format example of T.1 Altitude Simulation test:

VIII. Conclusion

IX. Photo of The Sample

What does the UN38.3 Test Report Mean for the Lithium Battery

It is a kind of certificate for assurance of quality.

We know that UN38.3 contains 8 different tests that simulate the different extreme environments that lithium batteries/cells or products with lithium batteries may encounter, such as vibration, load, short circuit, etc.

If it were not for transportation, our batteries in common application scenarios have rare chance to encounter these environments. UN38.3 test is another way to determine the product quality. In other words, If the lithium batteries/cells to be tested can pass all the UN38.3 test items, the quality of the lithium batteries/cells will be further proven to be excellent from a safety perspective.

What does the UN38.3 Test Report Mean to the Battery Manufacturer

1. Helps To Secure Orders

As I said above, lithium batteries/cells that can pass the UN38.3 tests can reflect the product quality to some extent, which means that a qualified UN38.3 report is the best advertisement and publicity for the quality of your batteries or cells.

As a battery manufacturer, when the customer asks about the safety and reliability of your batteries or cells, how do you convince your customer of the quality of products?

Do we speak only in words? It appears to be kind of pale, and usually, it doesn’t work that well, because clients have heard a lot about that kind of marketing language.

No amount of language is as good as an authoritative report like UN38.3 report. When you take out your UN38.3 test report and present it to the customer, you don’t have to say more and just let the customer read your report slowly. I believe that your customer will be full of praise for you in less than a minute and leave a very positive impression on him.

Besides, if the manufacturer has a UN38.3 certificate, the trader is more willing to cooperate with them, which can help them save a lot of troubles in the export process.

In summary, It will be able to help you win more customers’ trust and orders with the help of UN38.3.

2. Helps to Improve Product Quality

As a battery manufacturer, If you want to sell your products to different countries and regions worldwide, all the test requirements of UN38.3 should be taken into consideration in advance at the product development and design stage.

To make the finished products meet these testing requirements of UN38.3, manufacturers must develop products with higher standards, using better raw materials and processes to produce products, so that the overall product quality will be further improved.

After the finished products are made, they can easily pass the tests of UN38.3 and own the more substantial comprehensive competitiveness.

What does the UN38.3 Test Report Mean to the Exporter or Seller

A Gate Passes for Cargo Export

A UN38.3 test report is one of the vital gate passes when a shipper or export ships lithium batteries/cells or cargo containing batteries by air, truck and boat.

For lithium battery and lithium battery products such as mobile phone, laptop, digital camera etc., there is a potential danger in the process of transportation.

Conducting the UN38.3 test is to ensure transport security. Besides, according to the dangerous goods regulations of IATA(international air transport association), Airline companies and airport cargo receiving and transportation departments have to verify the transport documents of lithium batteries and the UN38.3 safety test report of each type of lithium batteries.

If the test report is not available, civil aviation will ban lithium batteries from air transport.

A Compulsory Obligation for Business

As a seller of lithium batteries or merchandises with lithium battery, If you can’t present the UN38.3 test report now, maybe you won’t have the opportunity to proceed with your regular business.

For example, the top-ranking e-commerce platform Amazon rules that As of January 1, 2020, lithium battery manufacturers and distributors must provide lithium battery test summaries following the United Nations Standard UN38.3. This new global requirement applies to all lithium batteries, cells, and products containing lithium batteries. If you don’t provide this test summary, Amazon will take your products off the shelves and not allow you to continue to sell on its platform.

With the continuous improvement and development of the e-commerce market and people’s increasing requirements on product quality, it is believed that in the future, more commercial platforms will require sellers who sell batteries and products with batteries to provide a UN38.3 test documentary.

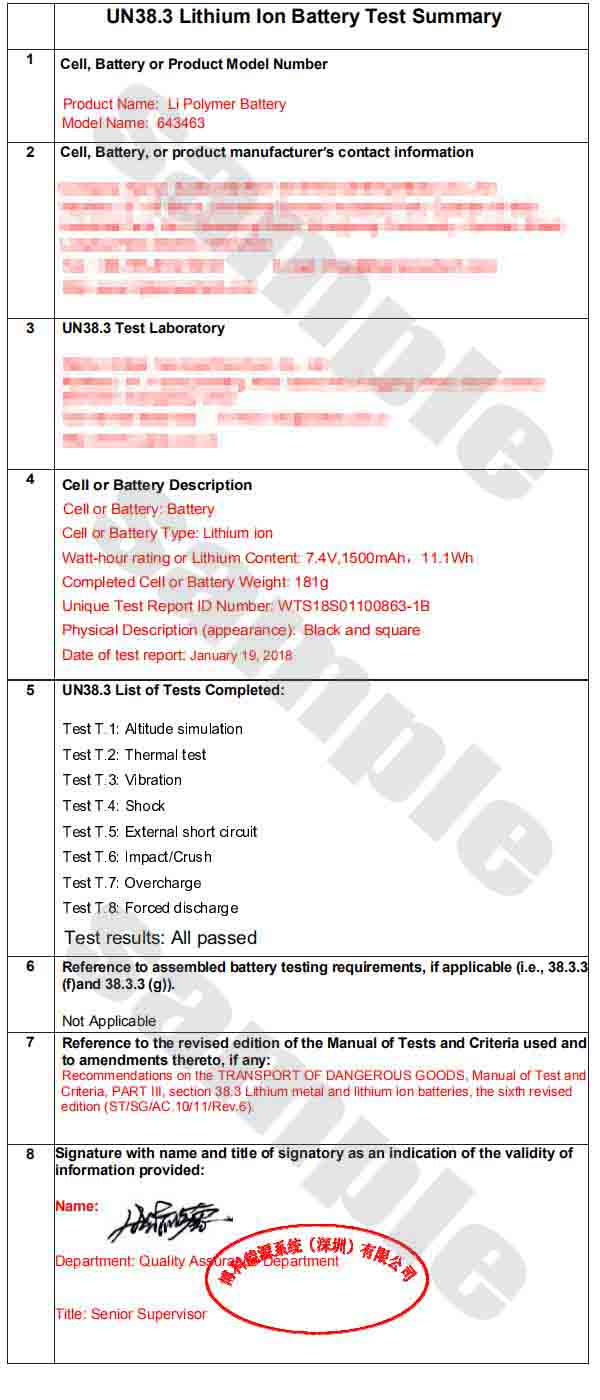

What’s the UN38.3 Test Summary, and What’s the difference from the UN38.3 Test Report

If letting me explain it with one sentence, I will tell you that the UN38.3 test summary is a simplified version of the UN38.3 test report. Compared with more than ten pages of the UN38.3 test report, the UN38.3 test summary only has one page, including 10 points.

A complete UN38.3 Test report is full of technicality, and the content is relatively lengthy. Non-professionals are not convenient to read and understand. For this reason, the United Nations expert committee changed the rules and simplified the test report content in the form of “Test Summary”. The summary is composed of 10 essential contents specified in the profile.

UN38.3 test summary is an essential document that has to be presented when shipping lithium batteries/cells or cargo with lithium batteries by air from January 1, 2020, which is ruled by the International civil aviation organization. Amazon also has required that all merchants selling lithium batteries or products containing lithium batteries must submit the UN38.3 test summary.

Content of Lithium Cell or Battery Test Summary

1)Name of the cell, battery, or product manufacturer, as applicable;

2)Cell, battery, or product manufacturer’s contact information to include address, phone number, email address and website for more information;

3)Name of the test laboratory to include address, phone number, email address and website for more information;

4)A unique test report identification number;

5)Date of test report;

6)Description of cell or battery to include at a minimum;

a.Lithium ion or lithium metal cell or battery.

b.Mass;

c.Watt-hour rating, or lithium content;

d.Physical description of the cell/battery; and

e.Model numbers.

7)List of tests conducted and results(i.e pass/fail);

8)Reference to assembled battery testing requirements, If applicable(i.e. 38.3.3(f) and 38.3.3(g));

9)Reference to the revised edition of the Manual of tests and Criteria used and to amendments thereto, If any; and

10)Signature with name and title of signatory as an indication of the validity of information provided.

Who Can Issue the UN38.3 Test Report/Summary

UN38.3 test report/summary can be issued by the third-party testing laboratories designated by the civil aviation industry, and also can be provided by lithium battery/cell manufacturers with testing capability.

Besides the UN38.3, What Else Requisite Documents Should be Provided for the Shipment of Lithium Battery Products by Air or Sea

The other documents include MSDS, 1.2m drop test report which is required for lithium battery shipped separately) and Identification and Classification Report for Air Transport of Goods or Identification and Classification Report for Air Transport of Goods.

Please note that owning the UN38.3 test report and MSDS report is the prerequisite before applying for Identification and Classification Report for Air/Sea Transport of Goods.

What’s the Difference Between the UN38.3 and the MSDS

UN38.3 is a safety test standard involving Lithium batteries or cells. The UN38.3 is part 38.3 of the United Nations Manual of Tests and Criteria for the Transport of Dangerous Goods, which requires that lithium batteries/cells must be subjected to high altitude simulation test, high and low-temperature circulation test, vibration test, impact test, external short circuit test, impact test, overcharge test and forced discharge test before transportation, to ensure the safety of lithium battery/cell transportation by air/land/sea.

MSDS(Material Safety Data Sheet) is the chemical safety technical specification, which is a document used by chemical producers and importers to clarify the physical and chemical properties of a chemical, including factors such as PH value, flash point, flammability, reactivity, etc., and the potential hazards to the user’s health (resulting in cancer or physical deformity).

Because different product models have different amounts of substances, various harmful elements, leading to different damages, each product model needs a single MSDS. Chemical products enterprises have a responsibility to provide security manual such as MSDS for users to let them understand the chemicals-related harms and make active protection during use, for having the effect of reducing occupational hazards and preventing chemical accidents.

At present, the United States, Japan, the European Union and other developed countries have generally established and implemented the MSDS system, which requires the manufacturers of hazardous chemicals to provide a safety manual of the product when selling, transporting or exporting.

No matter whether the lithium battery is shipped by sea or by air, the UN38.3 report and MSDS are required to be presented compulsively. Usually, when many people do battery testing, they often confuse UN38.3 with MSDS or think they are the same certification, which is not right and should be corrected.

What Are the Test Items For UN38.3 and Reasons Why Conduct These Tests

There are 8 different test items in total. Let’s check these items one by one.

T.1 Altitude Simulation

Common sense tells us that the higher altitude, the lower pressure. When an airplane takes off from the ground to its cruising altitude of 30,000 feet, the air pressure inside the plane slowly decreases as the altitude increases. When the plane lands, the air pressure inside the cabin increases gradually as the altitude decreases.

Although the aircraft shall pressurize and depressurize the cabin during ascent and descent, there is always a pressure difference that can’t be avoided. If a cargo plane carries lithium cells/batteries, or products with lithium batteries, how do we determine in advance whether the batteries inside the plane can withstand the pressure changes?

Thus, a chamber to simulate this type of high altitude with a low-pressure environment was born, its principle is very simple: in a sealed chamber, use the artificial method to generate a specified low-pressure environment, and put the lithium battery or lithium cell in the test chamber, after a specified time, then take out the battery or cell to evaluate whether it meets the standard.

T.2 Thermal Test

At the same time, the temperature of the world is very different between different countries and regions. If a battery is transported from low latitudes to high latitudes, the battery will experience a temperature difference from high to low temperature. Conversely, If transported from high latitudes to low latitudes, the battery will experiences a temperature difference from low to high temperature.

Not only that, If transported by cargo aircraft, the temperature is lower when it flies at a high altitude than that on the ground, and the temperature is also higher than that at high altitude when it lands. If shipped by sea, containers stuffed with lithium batteries/cells stack on the deck, also will experience a significant temperature difference between day and night while sailing on the water.

In short, batteries transported remotely must be subjected to extreme temperature variations.

The purpose of the thermal test is to use rapid and extreme temperature changes to evaluate lithium cell and battery seal integrity and internal electrical connections.

T.3 Vibration

This test simulates vibration during transport. Not only the battery, for any transportation of goods, the vibration is difficult to avoid because any object displacement represents the occurrence of movement, accompanied by vibration.

In the process of handling, loading, transportation and unloading, vibration is unavoidable.

Take the example for air transport, barring turbulence in the air, the cargo hold vibrates continuously at a fixed frequency, even if the aircraft is usually cruising. This kind of vibration may not be felt by human perception, so it is directly ignored for common goods, but for such dangerous and sensitive goods like batteries, we should pay considerable attention to it in case of catching fire.

We need to simulate this similar environment ahead of time to see If the battery can maintain stable physical and chemical properties in such a vibration conditions and do not have other abnormalities.

T.4 Shock

When we usually take a passenger plane, the flight often appears up and down, left and right sway and fuselage vibration suddenly. This phenomenon is caused by atmospheric turbulence.

The reason why the airplane is bumpy is that there is turbulence in the atmosphere, varying in size, direction and speed.

When an aircraft enters a turbulence vortex similar to the size of the body, each part of the aircraft will be affected by airflow in different directions and speeds, and the original balance of aerodynamic force and torque will be destroyed, thus producing irregular movement. When an airplane moves from one vortex to another, it vibrates. When the aircraft’s natural vibration period is same as the turbulence pulsation period, the turbulence becomes very intense.

Once we understand the reason behind this phenomenon, you must know the necessity for a shock test for the batteries that will be airlifted.

Think about it, If the batteries which can’t withstand these shocks collide in the cabin due to turbulence at the height of 10,000 meters to cause a fire, which will be very terrible and disastrous.

T.5 External Short Circuit

This test simulates an external short circuit. Battery short circuit is a common fault of batteries, including external short circuit and internal short circuit.

The External short circuit generally refers to the short circuit caused by direct contact between positive and negative poles. No matter whether by sea, by air or by truck, external short circuit may occur in case of abnormal packaging, accidental changes in the external environment, or improper human handling.

When the battery short circuit occurs, the battery will continue to release heat, and the temperature is very high enough to melt the general metal. If there is no timely heat dissipation, It will burn out the battery, and cause fire or even explosion, becoming a serious threat to property and life safety.

We do this external short circuit test to know whether the battery is in controlled condition once the external short circuit happens.

T.6 Impact/Crush

These tests simulate mechanical abuse from an impact or crush that may result in an internal short circuit. Internal short circuit refers to the short circuit in the region of the battery affected by external objects when the battery is punctured by a sharp object or is collided or squeezed.

The primary purpose of this test is to test the internal stability and safety of the cell to prevent the battery from disintegrating or catching fire in the process of the sea, truck or air transportation due to externally uncontrollable factors, such as impact, dumping, collapse and so on.

These tests are only applicable to lithium cells less than 18mm in diameter.

T.7 Overcharge

This test assesses the performance of a rechargeable battery or a single cell rechargeable battery to resist an overcharge condition.

The battery is charged using a charge current and a charge voltage that exceeds the battery manufacturer’s specified values to know whether the specimen can meet the requirements of no disassembly and fire.

T.8 Forced Discharge

This test evaluates the ability of a primary or a rechargeable cell to withstand a forced discharge condition. Connect each cell in series with a 12V DC power supply at an initial current equal to the maximum discharge current specified by the manufacturer.

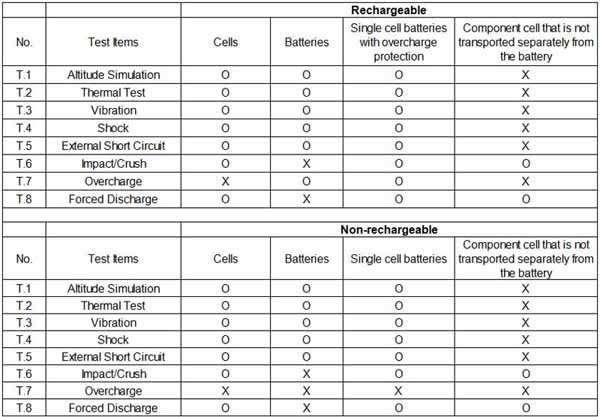

What Is the Test Scope of the UN38.3 Standard

1. All cell types shall be subjected to tests T.1 to T.6 and T.8.

2. All non-rechargeable battery types, including those composed of previously tested cells, shall be subjected to tests T.1 to T.5.

3. All rechargeable battery types, including those composed of previously tested cells, shall be subjected to tests T.1 to T.5 and T.7.

4. In addition, rechargeable single cell batteries with overcharge protection shall be

subjected to test T.7.

5. A component cell that is not transported separately from the battery it is part of needs

only to be tested according to tests T.6 and T.8.

6. A component cell that is transported separately from the battery shall be subjected to tests T.1 to T.6 and T.8.

How to Determine Whether the Test Results of UN38.3 Are Qualified

♦♦ T.1-T.4 Cells and batteries are qualified if there is no leakage, no venting, no disassembly, no rupture and no fire during the test and after the test and if the open circuit voltage of each test cell or battery after testing in its perpendicular mounting position is not less than 90% of its voltage immediately prior to this procedure.

♦♦ T.5-T.6 Cells and batteries meet this requirement if their external temperature does not exceed

170 °C and there is no disassembly, no rupture and no fire during the test and within six hours after the test.

♦♦ T.7-T.8 Primary or rechargeable cells meet this requirement if there is no disassembly and no fire during the test and within seven days after the test.

Can Various UN38.3 Tests Be Performed in A Single Chamber

The 8 test items can not be performed in a single Chamber, because it is impossible for one piece of equipment to accommodate all testing functions of 8 different projects.

What Testing Equipment Are Used for the UN38.3 Certification

There are some different test Chambers to be used for the UN38.3 tests, including Altitude Simulation Test Chamber, Thermal Test Chamber, Electrodynamic Vibration Tester, Shock Tester, External Short Circuit Tester, Cell Impact Tester, Cell Crush Tester, Explosion Proof Test Chamber, Charge-discharge Tester.

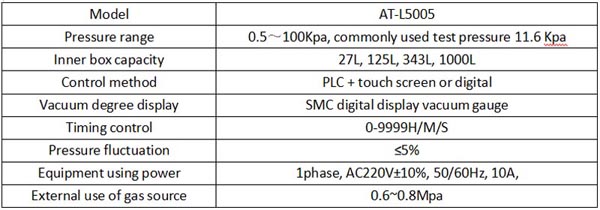

1. Altitude Simulation Test Chamber

Altitude Simulation Test Chamber is with a internal capacity of 27 L, 125 L or larger volumes, featuring a cabinet which can create a constant low pressure environment from 0.5 kPa to 100 kPa. The specimen is stored at this pressure of 11.6 kPa for at least 6 hours at ambient temperature (20 ± 5)℃.

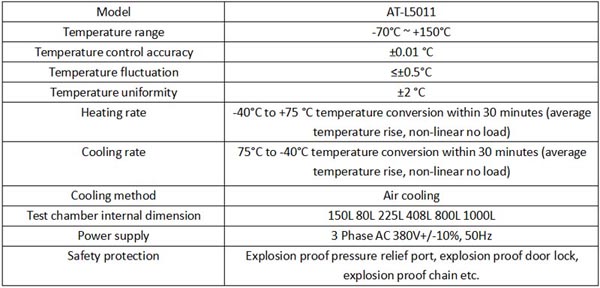

2. Thermal Test Chamber

Thermal Test Chamber can create rapid and extreme temperature changes inside the inner chamber in which the specimen is placed. It has an extremely wide temperature range of – 70℃ ~ + 150℃. The heating time from – 40℃ to + 75℃ is 30 minutes and that from + 75℃ to – 40℃ is also 30minutes. The uniformity of temperature is ±2℃. The side of the test chamber is equipped with a cable hole and a pressure relief hole in case of a battery explosion.

There are two quality compressors to achieve rapid cooling and an efficient electric heater to heat the temperature to meet the testing requirements.

Test cells and batteries are to be kept for a minimum of 6 hrs at a test temperature equal to 75 ± 2 ° C, followed by storage for at least 6 hrs at a test temperature level equivalent to – 40 ± 2 ° C. The maximum time interval between test temperature extremes is half an hour. This procedure is to be duplicated until 10 overall cycles are complete, after which all test cells and batteries are to be kept for a 24-hour at ambient temperature (20 ± 5 ° C). For giant cells and batteries, the duration of exposure to the test temperature extremes should be at least 12 hours.

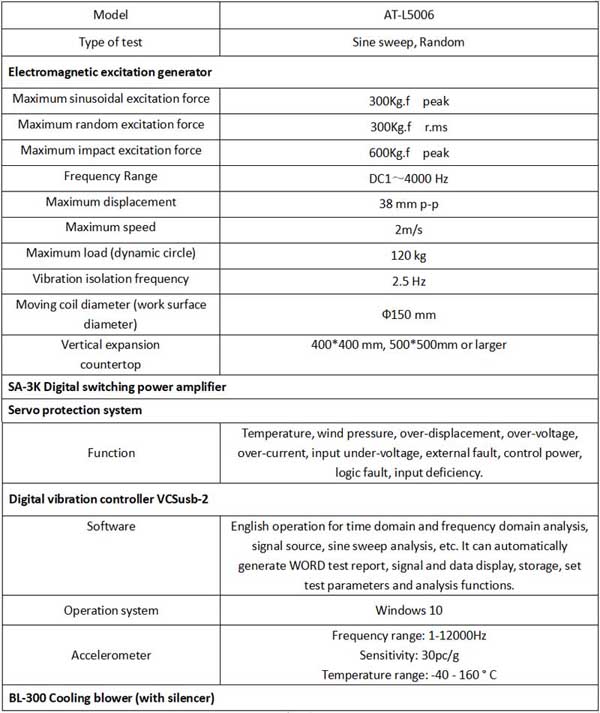

3. Electrodynamic Vibration Tester

Electromagnetic Vibration Tester can simulate the vibration of the sinusoidal waveform to evaluate the safety performance of a cell or battery.

Cells or batteries are firmly fixed to the platform of the vibration equipment without misshaping the cells in such a way as to transmit the vibration faithfully. The vibration shall be a sinusoidal waveform with a logarithmic sweep between 7 Hz and 200 Hz and return to 7 Hz passed through in 15 minutes. This cycle shall be duplicated 12 times for a total of 3 hours for each of three mutually vertical mounting positions of the cell. One of the directions of vibration must be perpendicular to the terminal face.

The logarithmic frequency sweep shall differ for cells and batteries with a gross weight of not

more than 12 kg (cells and tiny batteries), and for batteries with a gross weight of more than 12 kg (large batteries).

For cells and small batteries: from 7 Hz, a peak acceleration of 1 gn is kept until 18 Hz is attained. The amplitude is then kept at 0.8 mm (1.6 mm total excursion), and the frequency increased until a peak acceleration of 8 gn happens (approximately 50 Hz). A peak acceleration of 8 gn is then kept until the frequency is raised to 200 Hz.

For large batteries: from 7 Hz to a peak acceleration of 1 gn is kept until 18 Hz is attained. The amplitude is then kept at 0.8 mm (1.6 mm total excursion), and the frequency increased until a peak acceleration of 2 gn occurs (approximately 25 Hz). A peak acceleration of 2 gn is then maintained until the frequency is raised to 200 Hz.

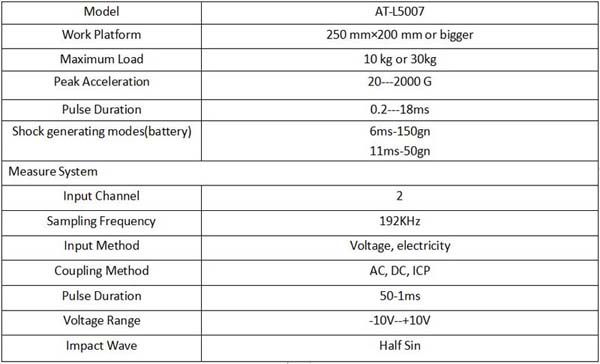

4. Shock Tester

Shock Tester is used to evaluate the robustness of cells and batteries against cumulative shocks.

Test cells and batteries shall be secured to the testing machine by a mean of a rigid mount

which will support all mounting surfaces of each test battery.

Each cell shall be subjected to a half-sine shock of peak acceleration of 150gn and pulse duration of 6 milliseconds. Alternatively, large cells may be subjected to a half-sine shock of peak acceleration of 50gn and pulse duration of 11 milliseconds.

Each cell or battery shall be subjected to three shocks in the positive direction and three shocks in the negative direction in each of three mutually perpendicular mounting positions of the cell or battery for a total of 18 shocks.

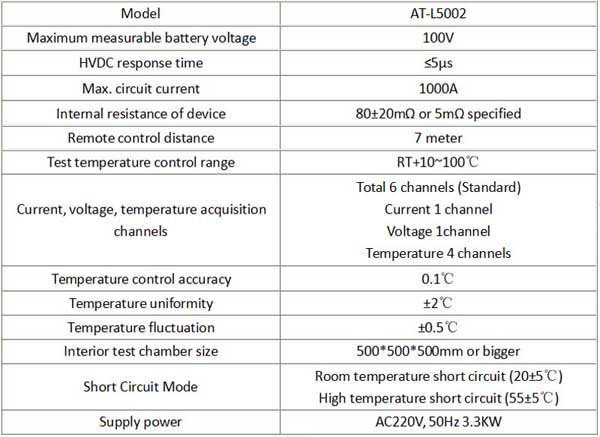

5. External Short Circuit Tester

External Short Circuit Tester is intended to simulate an external short circuit of specimen at a specified temperature to evaluate the security performance.

The cell or battery to be evaluated shall be heated up for the amount of time necessary to reach a uniform stabilized temperature of 57 ± 4 ° C, determined on the external case. This amount of time depends upon the size as well as style of the cell or battery and should be evaluated and documented.

If this evaluation is not practical, the exposure time shall be at least 6 hrs for tiny batteries as well as tiny cells and 12 hrs for big cells and large batteries. Then the cell or battery at 57 ± 4 ° C shall go through one short circuit condition with a complete external resistance of less than 0.1 ohm.

This short circuit condition is proceeded for at the very least one hr after the cell or battery external case temperature level has gone back to 57 ± 4 ° C, or when it comes to the big batteries, has actually decreased by fifty percent of the maximum temperature boost observed during the test as well as stays below that value. The short circuit and cooling down phases shall be conducted at least at ambient temperature level.

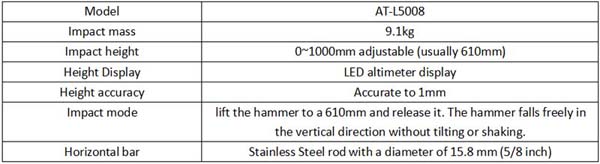

6. Cell Impact Tester

Cell Impact Tester is used to determine the safety performance of cell subjected to impacting, suitable for cylindrical cells not less than 18.0mm in diameter.

A 316 stainless steel bar is to be put across the centre of the sample. A 9.1 kg ± 0.1 kg mass is to be dropped from an elevation of 61 ± 2.5 centimeters at the intersection of the bar and a sample in a controlled way utilizing a near frictionless, vertical gliding track or channel with minimal drag on the falling mass. Each specimen only suffers a single impact.

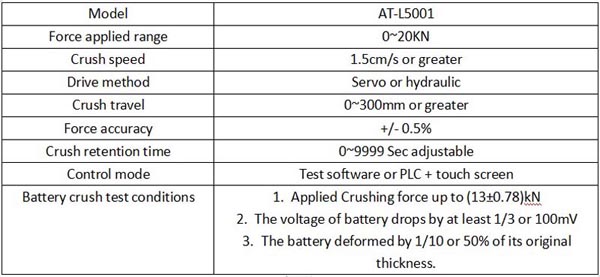

7. Cell Crush Tester

Cell Crush Tester is intended to determine the safety performance of cell subjected to crushing. Suitable for the prismatic, pouch, coin/button cells and cylindrical cells less than 18.0 mm in diameter.

A cell or component cell is to be crushed between 2 level surfaces. The crushing is to be

gradual with a rate of around 1.5 cm/s at the initial point of contact.

Once the maximum pressure has actually been obtained, the voltage drops by 100 mV or more, or the cell is deformed by at least 50% of its initial thickness. The pressure shall be released.

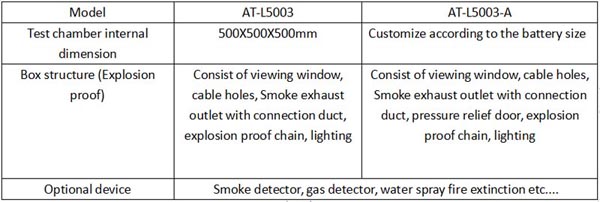

8. Explosion Proof Test Chamber & Charge-discharge Tester

Using Explosion Proof Test Chamber to conduct overcharge and forced discharge tests is in order to ensure safety throughout the test.

When the operator is overcharging and forced discharging the cell or battery, which is involved with extremely high current and voltage which exceed the values specified by manufacturers, catching fire and explosion are possible to occur during the test.

An Explosion-proof test chamber is a specially designed equipment featuring a rigid cabinet to withstand all damages due to explosion, to safeguard the operator and other equipment in the laboratory.

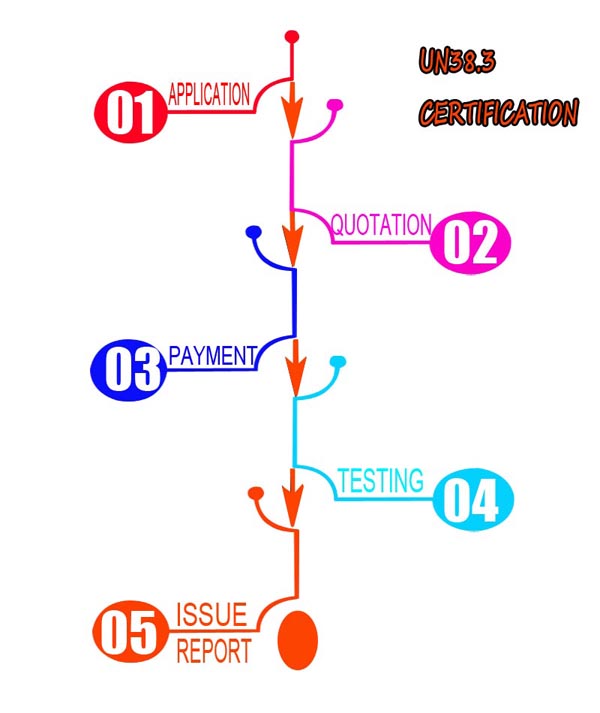

What’s the Procedure to Get a UN38.3 Certification From a Third-Party Testing laboratory

Application

1. Fill out the application form.

2. Submit a power of attorney, Lithium battery transportation statement and other random files.

3. Provide Specifications of the battery to be tested.

4. Offer samples

a. Samples should be marked with the model number, voltage, rated capacity, watt-hour (Wh), ensuring that they are consistent with the batteries to be shipped.

b. Regarding the sample quantity to be provided, please submit based on what the testing agency requires. It varies with different battery types and battery capacities. Generally, for regular lithium battery,16pcs batteries and 30pcs cells need to be provided.

5. Provide the packaging pictures layer by layer

a. Photos of the inside and outside conditions of the outer packing box (labels and marks should be shown clearly);

b.Pictures of the inside and outside of the inner packaging box;

c. Device picture:

d. photo of the battery packaged with the device or the battery installed in the device.

How Many Days Does it Take to Get a UN38.3 Certification

Generally, it takes about two weeks to complete all test items, then takes one week to issue report and certification, so that the total time will be at least three weeks.

How Much is the Cost of the UN38.3 Test Conducted by a Third-party Testing laboratory

There is no fixed price. It depends on the capacity and type of battery/cell to be tested. The larger the battery/cell is, the more expensive it will be. In addition, the cost is also related to market competitiveness. If your country only has one eligible UN38.3 testing laboratory, for sure, that will be more expensive.

In China, there are many such testing laboratories in the market. The cost of a set of UN38.3 test is likely to be at least $2,000.

How Long Is the UN38.3 Certification Valid

Unlike the Identification and Classification Report for Air/Sea Transport of Goods and MSDS, which are expired automatically on December 31st every year, UN38.3 has no expiration date unless the UN38.3 standard is updated.

The UN38.3 Test Standard

Final Thoughts

By the time you read up here, you must already have a fair knowledge of the UN38.3 and UN38.3 test, which was born for lithium batteries, and has made a significant contribution to lithium batteries’ transportation and global popularity.

With the development of human society, lithium battery has increasingly become more and more indispensable for us. Without lithium batteries, our smartphones, tablets, and laptops might be worthless. The safety of lithium batteries has always been a topic of discussion. At present, there is no perfect solution that can prevent the burning or explosion of lithium batteries. Consumers should choose high-quality lithium batteries and pay attention to battery safety regulations. The manufacturers has obligation to improve the safety performance of the battery by enhancing the safety protection design of the battery, increasing the thermal stability of the electrode material, and using safe electrolytes.

Amadetech is a professional manufacturer and supplier of Lithium Battery Testing Equipment from China, which can provide a complete set of UN38.3 testing equipment to all countries and regions around the world.

Standardized and customized services meet the different testing requirements. Testing machines from Amadetech are applied to UN38.3 testing and compatible with other latest testing standards of IEC62133 UL1642 UL2054 IEC62619 EN50604, etc.

China is the world’s largest producer of lithium batteries. Many lithium battery manufacturers have purchased our lithium battery testing equipment. We also can recommend you some reliable Lithium battery manufacturers If you are sourcing batteries.

If you have any more questions, please feel free to contact us by email: [email protected].

Your satisfaction is our greatest happiness.