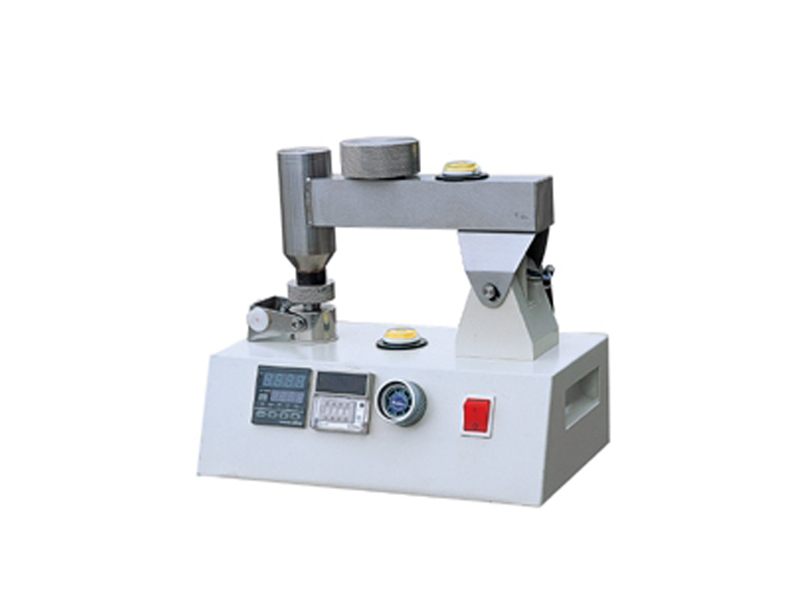

Safety Shoes Soles & Uppers Hot Contact Resistance Tester China Supplier

Shoe Materials Heat Resistance Tester is used to test the high-temperature resistance of the soling of sole materials, shoe uppers and shoe linings, etc. It is a vital footwear testing machine.

The test sample is placed to contact a heat source – a square end of copper bit under a static pressure for a specified time (about 60 seconds). Any surface damage, such as melting, softening, cracking, etc., is inspected visually to evaluate the sample’s property of hot resistance.

Test Standards

- EN-344-1 section 5.18 Determination of resistance to hot contact

- SATRA TM49 Resistance to damage due to contact with a hot surface

- GB/T 20991 section 8.7 Determination of resistance to hot contact

- AS/NZS 2210.2 section 8.7 Determination of resistance to hot contact

- ISO 20344 section 8.7 Determination of resistance to hot contact

- BS 5131 Part 2.11 Methods of test for footwear and footwear materials – Soling – Resistance of soling to short-term contact with a hot surface

Main Technical Parameters

| Model | AT-F3046 |

| Cylindrical Copper Body | Mass 200 ± 20 g, Lower end surface dimension: 25.5 × 25.5 mm |

| Metal Heating Block | 530 ± 50 g |

| Test Pressure | 20 ± 2 kPa |

| Test Time | 60s (adjustable) |

| Test Temperature | 300 ± 2℃ (100 ~ 400℃) |

| Self-aligning Platform | Diameter 40 mm |

| Dimension | 30 × 19 × 30 cm |

| Weight | Appr. 14 kg |

| Power Supply | 1 phase, AC 220V or specified |

Features of Sole Heat Resistance Tester

- Configured with a cylindrical copper bit with a mass of 200 ± 20 g, and its bottom is cut into a square with a side length of 25.5 ± 0.1 mm. The copper bit has a cylindrical cavity with a diameter of 6.5 mm. The bottom of the cavity is 4 mm beyond the bottom plane of the copper bit, which is connected to a temperature measuring device.

- A metal heating block with a mass of 530 g surrounds the circumference of the copper bit. It contains an electric heating element that can preheat the copper bit to 400°C.

- Equipped with a temperature control device inside the copper bit, automatically probe and control the heating temperature.

- Fitted with a self-aligning platform with a suitable diameter to place the test piece and apply uniform pressure.

- The machine has a hinged insulated support. The user puts it aside when the copper body is heating and puts it in position during the test.

- It has a simple structure for ease of operation and maintenance.

Test Method of Sole Heat Resistance(for Reference)

- Turn on the heating block with the bit resting on the insulating support and place the test piece on the platform below with its wear side uppermost.

- Use aluminum foil to cover the test piece to prevent contamination of the heated bit.

- When the temperature has just surpassed 300 ± 5℃ measured on the outer plate, with the bit still resting on its insulating support, then move the insulating support aside and immediately place the bit centrally on the test piece.

- Keep it in position for 60 ± 1 s without switching the heating block on again and then replace it on the support.

- Take off the foil, permit the specimen to cool for at least 10 minutes, then inspect the damage status for result evaluation.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.

Related Products

AmadeTechAdmin2021-09-17T08:09:28+00:00

AmadeTechAdmin2021-09-17T08:11:16+00:00

AmadeTechAdmin2021-09-17T08:12:15+00:00

AmadeTechAdmin2021-09-17T08:12:26+00:00

AmadeTechAdmin2021-09-17T08:12:45+00:00

AmadeTechAdmin2021-09-17T08:13:07+00:00

AmadeTechAdmin2021-09-17T08:13:28+00:00

AmadeTechAdmin2021-09-17T08:14:03+00:00