Penetration-resistant Insert Bending Resistance tester for Protective Footwear

Penetration Resistant Inserts Flexing Tester is designed for preforming the test of resistance of safety shoe’s penetration-resistant insert to flexing.

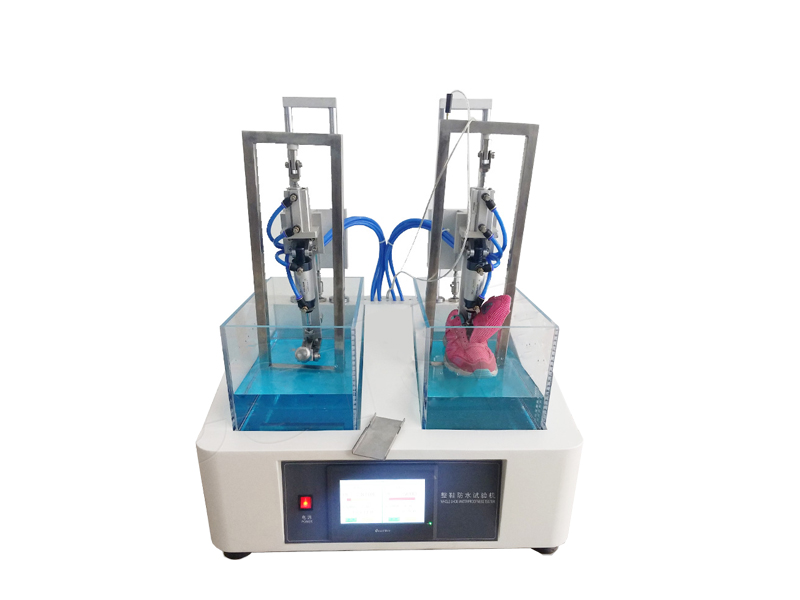

The flexing apparatus comprises a suitable flexing guide to move the free end of insert through a specified distance at a given rate, and a clamping device consisting of two elastic inter-layers 4 mm thick and shore A hardness 75±5 with two metal clamping plates at least 130mm wide. The guide acts at a distance of 70mm from the clamping plates and the specimen is clamped with two fixed rods. In order to accommodate all sizes of inserts, the flexing line can be shifted by up 10 mm in the direction of the heel. The machine shall be suitable to perform the flex test at a frequency of 16 ± 1 Hz.

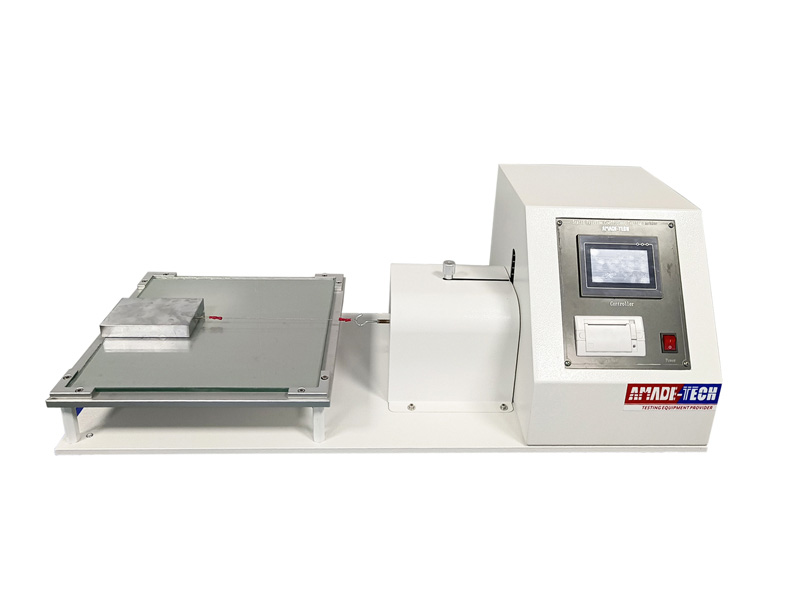

As the flexing frequency of this shoe testing machine is as high as 16Hz, which leads to the rampant vibration of the whole testing machine during the test, the control box is designed to separate from the core device to extend the equipment’s service life.

Test Standards

EN 12568 7.2.2

ISO 20344 5.9 Determination of the flex resistance of penetration-resistance inserts

AS/NZS 2210.2 Section 5.9, etc.

Main Technical Parameters

| Model | AT-F3031 |

| Flexing Frequency | (16 ± 1) Hz |

| Max. Vertical Flexing Height | 33 mm |

| Flexing Distance | 70 mm |

| Number of Test Stations | 2 |

| Counter | LCD, 0 ~ 999,999 |

| Power Supply | 1 Phase, AC 220 V, 50/ 60 Hz or specified |

Features

- This penetration-resistant inserts flexing tester owns two sets of clamps, which can be used to test on two samples simultaneously.

- The vibration body and controller are separated to protect and extend the service life of the instrument.

- Tester has the function of automatic stop, which means that the machine can automatically stop when reaching the preset number of flexes.

- A digital display screen is available to indicate the real-time running data.

- Equipped with quality accessories adding precision design to ensure the stable flexing performance.

- The test machine is mounted with a protective cover in case that the specimen pops out by accident during the test.

- It supports the functions of manual adjustment and reset.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.