IPX 3/4/4K Waterproof Test Chamber China Manufacturer and Supplier

The IPX3/IPX4/IPX4K Water Spraying & Splashing Test Equipment is a versatile 3-in-1 solution designed to evaluate the ingress protection of enclosures against spraying (IPX3) and splashing water (IPX4/4K). This integrated system allows users to switch between testing ratings seamlessly by adjusting the number of nozzles on the oscillating tube or swapping needles to match required inner diameters. Compared with IPX3 and IPX4, the IPX4K configuration introduces increased water pressure to simulate extreme environmental conditions.

IEC60529 Compliant Oscillating tube and Nozzles

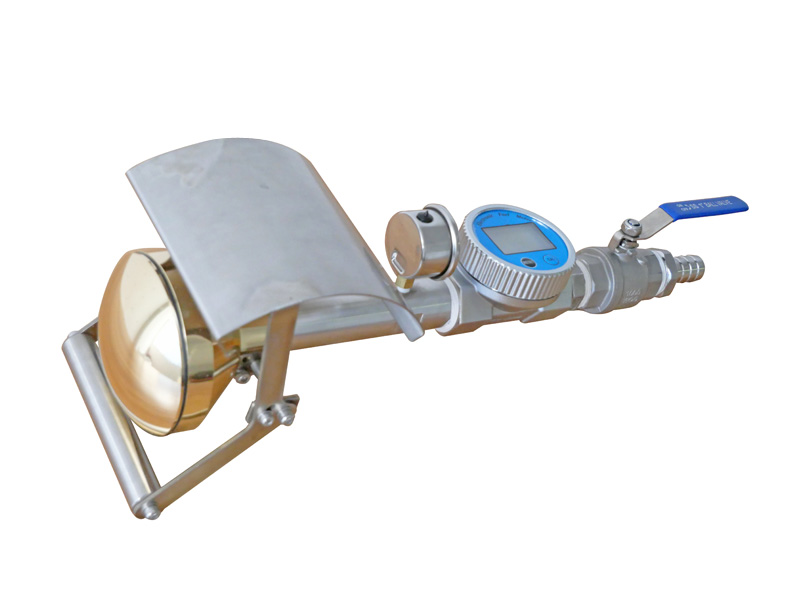

Constructed from high-quality stainless steel, the oscillating tube features a semi-circular design with precision-drilled holes directed toward the center. Each port is equipped with a threaded fitting, allowing for the easy manual installation of spray nozzles and plugs. During operation, water is ejected from the needle in a concentrated stream, providing direct impact on the specimen’s housing to ensure accurate testing results.

To accommodate various sample sizes, the system offers oscillating tubes with multiple radii. The IPX3 oscillating tube sprays water over the sample at an angle up to 60° on either side of the vertical, and the IPX4 oscillating tubes splashes water over the sample from any direction. While IPX4K utilizes the same foundational parameters as IPX4, it operates at higher pressure and flow rates to simulate more severe exposure. All tests require maintaining a standardized 200mm spray distance between the enclosure and the needles. The interior is also outfitted with integrated lighting and a built-in power socket for the Test Under Load (TUL) of the sample.

IPX3/4 oscillating tube water ingress test chamber

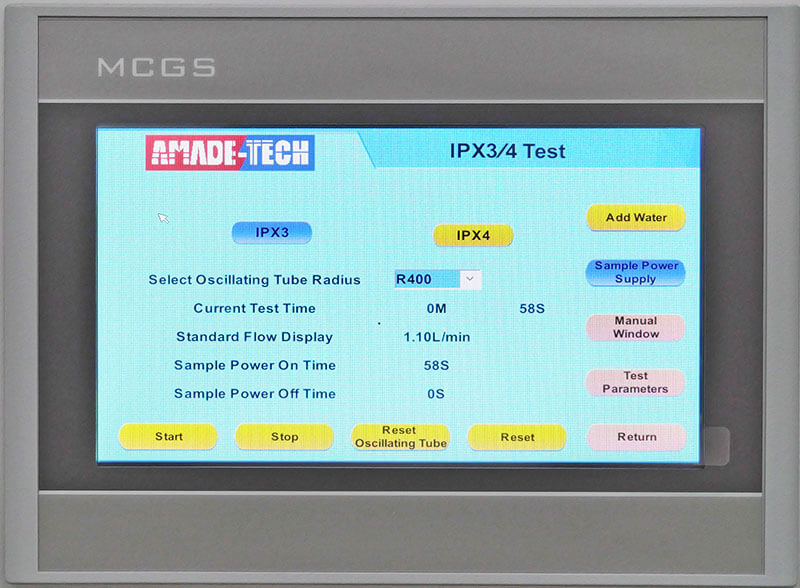

Intuitive Control System

The chamber is controlled via a 7-inch PLC touchscreen HMI, which integrates monitoring, control, and automated testing into one user-friendly interface. Operation is straightforward: simply power on the unit, use the “Add Water” function to fill the reservoir, select your desired IP rating, and set the test duration. The screen provides real-time data on elapsed time and sample power status, automatically concluding the cycle once the preset parameters are met.

Control panel

IPX3 / IPX4 test demo video

IPX4K test demo video

Open-type IPX3 IPX4 water spray tester

Open-Type vs. Box-Type Solutions

In addition to our integrated box-type rain test chambers, we offer open-type IPX3/4/4K spraying and splashing test equipment for specialized applications. While our standard box-type units typically feature a maximum oscillating tube radius of 800 mm—making them ideal for small to medium-sized products—our open-type systems provide much greater flexibility.

Engineered for Large-Scale Specimens

The open-type configuration allows the oscillating tube radius to extend up to 1600 mm. By removing the constraints of an enclosed chamber, this equipment is the perfect solution for testing large-dimension specimens that cannot fit into standard cabinets. However, please note that unlike self-contained box-type units that can be placed anywhere in a facility, open-type equipment requires a dedicated waterproof room or specialized test site to manage water runoff.

Customizable Configurations

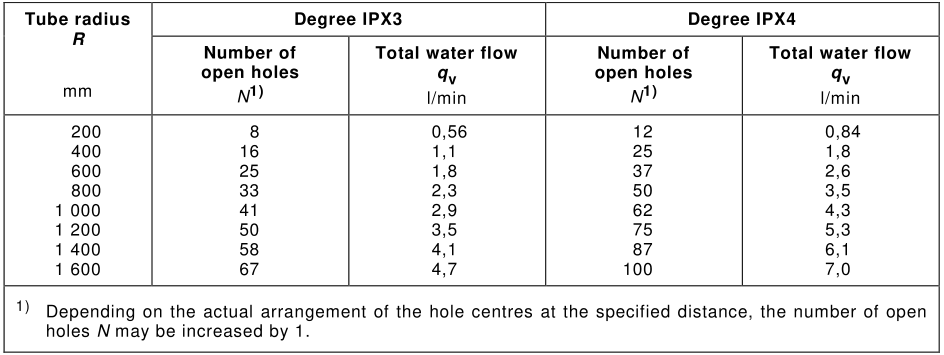

We provide fully customizable specifications to accommodate your specific testing needs. Our swivel tubes are available in eight standard radii: R200, R400, R600, R800, R1000, R1200, R1400, and R1600. As the radius increases, the number of nozzle openings and the total water flow rate are adjusted accordingly to ensure full compliance with international testing standards.

Custom Integrated Test Solutions

If you need to perform multiple levels of IP testing but wish to avoid the cost and footprint of multiple machines, AmadeTech has the answer. We can integrate the hardware for IPX1 through IPX6, and even IPX9K, into a single, multi-functional test chamber. This all-in-one approach significantly streamlines your testing workflow and maximizes laboratory space. Contact our experts today to discuss your custom testing requirements.

Solutions for Complex Specimen Geometries

Certain specimens feature complex shapes or external barriers that prevent an oscillating tube from reaching every surface. In these instances, the IPX3/IPX4 hand-held spray nozzle is the ideal solution. This manual tool bypasses the fixed angles of automated systems, allowing you to direct the spray toward any part of the enclosure for total coverage.

Click HERE to learn more about our hand-held spray nozzle solutions.

IPX3/4 hand-held spray nozzle

A complete IP testing equipment based on IEC60529 and ISO 20653 is also available at AmadeTech. Please click HERE to learn more.

Conforming Test Standards

- IEC 60529

- ISO 20653

- DIN 40050-9

- IEC 60598-1

- IEC 60068-2-18

- IEC 60034-5

Main Technical Specifications

Model | AT-C1005B-200 | AT-C1005B-400 | AT-C1005B-600 | AT-C1005B1-600 | AT-C1005B1-800 | AT-C1005B1-1000 | AT-C1005B1-1200 | AT-C1005B1-1400 | AT-C1005B1-1600 | |||

Equipment type | Box-type with an enclosed chamber | Open-type | ||||||||||

Oscillating tube radius | R200 mm | R400 mm | R600 mm | R600 mm | R800 mm | R1000 mm | R1200 mm | R1400 mm | R1600 mm | |||

Turntable diameter | Dia. 200 mm | Dia. 400 mm | Dia. 600 mm | Dia. 400 mm | Dia. 600 mm | Dia. 800 mm | Dia. 800 mm | Dia. 800 mm | Dia. 1000 mm | |||

Overall dimensions | (W) 955 x (D) 700 x (H) 1450 mm | (W) 1350 x (D) 1120 x (H) 1770 mm | (W) 1750 x (D) 1550 x (H) 1950 mm | (W) 1950 x (D) 1250 x (H) 1550 mm | (W) 2450 x (D) 1650 x (H) 1950 mm | (W) 2850 x (D) 2050 x (H) 2350 mm | (W) 3200 x (D) 2450 x (H) 2700 mm | (W) 3580 x (D) 2850 x (H) 3100 mm | (W) 4000 x (D) 3250 x (H) 3530 mm | |||

Turntable height range | 150 ~ 250 mm adjustable | 350 ~ 600 mm adjustable | 550 ~ 1000 mm adjustable | 770 ~ 1200 mm adjustable | 1000 ~ 1400 mm adjustable | 1300 ~ 1700 mm adjustable | 1500 ~ 1900 mm adjustable | 1600 ~ 2000 mm adjustable | 1700 ~ 2100 mm adjustable | |||

Spacing of holes | 50 mm | |||||||||||

Number of spray holes | As per specific test requirements | |||||||||||

Hole diamter | Dia. 0.4 mm for IPX3/IPX4, and Dia. 0.8 for IPX4K | |||||||||||

Oscillating angle of tube | ± 60° for IPX3 / ± 180° for IPX4/4K | |||||||||||

Turntable loading capacity | Max. 50 kg or customized | |||||||||||

Turntable rotating rate | 1 ~ 5 RPM adjustable | |||||||||||

Control mode | PLC + 7-inch touch screen | |||||||||||

Feature | Allows energized samples during the test | |||||||||||

Key Features of AmadeTech IPX3/4/4K Test Systems

Superior Construction & Design

- Premium Materials: The inner test chamber is constructed from high-grade SUS304 stainless steel for maximum corrosion resistance and durability.

- Enhanced Visibility: The box-type chamber features a large tempered glass observation window, allowing for clear monitoring of the specimen during testing.

- Flexible Configurations: Available in both integrated box-type (enclosed) and open-type (enclosure-free) designs to suit various laboratory spaces and sample sizes.

- Universal Compatibility: A single system is compatible with multiple oscillating tube specifications, allowing for seamless transitions between IPX3, IPX4, and IPX4K testing.

Advanced Water Management

- Automatic Replenishment: Integrated water-level sensors ensure the system automatically refills the reservoir as needed.

- Eco-Friendly Recycling: Box-type units include a built-in water circulation system, significantly reducing water consumption through efficient recycling.

- Nozzle Protection: A high-efficiency filtration system is installed in the storage tank to prevent impurities from clogging the spray nozzles.

- Precision Monitoring: Equipped with high-precision flow meters to provide real-time monitoring and ensure compliance with strict testing standards.

Smart Control & Functionality

- Intuitive HMI: Features a PLC controller and a 7-inch color touchscreen, providing a user-friendly interface for setting parameters and monitoring test progress.

- Adjustable Turntable: The sample turntable is fully adjustable in both height and rotational speed, accommodating a wide variety of specimen geometries.

- Testing Under Load: An internal waterproof power socket is available for testing energized (live) samples.

Comprehensive Safety Systems

- Door Safety Sensor: For box-type units, the machine features an automatic shut-off mechanism that triggers if the door is opened during operation.

- Electrical Protection: Fully equipped with a suite of safety devices, including overload protection, short-circuit protection, and earth leakage protection.

Frequently Asked Questions (FAQs)

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales specialists will respond within one working day.