Spectacle Frame Sprung Joint Durability Tester China factory and Supplier

Hinge Cycle Tester is used to determine the durability of the spectacle frame spring hinges and temples subjected to a specified number of repeated bendings through a given angle.

The simulation behaviours using this tester allow you to inspect and master the elasticity change of the sprung joints during actual use and the ability to resist repeated opening and closing of the temple, which also has a positive effect on material selection and quality control.

Frame Sprung Joint Durability Test Principle

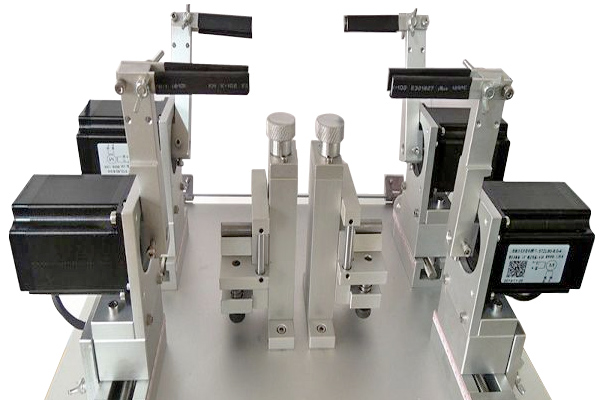

The rim portion of the spectacle frame specimen is fixed in a horizontal fixture on the platform. The temples face upwards, and both temple tips are restricted in the corresponding swingable holding devices. The inward or outward opening and closing angle of the frame sides, the number of cycles, the running speed and the interval time between single cycles need to be preset. The machine runs automatically until the predetermined number of cycle swings is completed. The test result is determined by checking elasticity changes and whether the spring hinge remains as it is.

Description for the Frame Durability Tester

Our spectacle frame spring hinge cycle tester features a PLC to run automatically for 4 swing heads according to your settings. Coupled with an LCD touch screen, It allows you to input the oscillation speed, the number of oscillations, interval, and forward and backward bending angle of a single swing head based on the testing requirements. The swing head supports front and back angles settings for the bending from -180° to 180°, which can satisfy all requirements for swing angles.

There are 2 workstations in this hinge cycle tester to accommodate 2 samples for testing simultaneously. Samples without rims are also accepted with the help of special auxiliary devices. Each station operates independently relative to the other. You can set their parameters individually and actuate either one or both to work at the same time. The test run can be automatically stopped as preset or manually suspended anytime for sample inspection.

For other spectacle frame testing devices, please go Here to learn more.

2 work stations

Main Technical Parameters

| Model | AT-DR3001 |

| Control mode | PLC + Touch screen |

| Work stations | 2 |

| Counter | 0~999,999,999 adjustable |

| Swing sngles of each head | Front angle: -180° to 180° adjustable

Back angle: -180° to 180° adjustable |

| Test speed | 0~120 cpm |

| Interval between each bending | 0~10 s adjuatable |

| Dimensions | 45 mm (W) × 47 mm (D) × 56 mm (H) |

| Power supply | AC 220 V 50 Hz / 110 V 60 Hz |

Hinge Cycle Tester Features

- Made of quality steel and the surface is coated with stoving varnish.

- Comes with the control mode of PLC plus a touch screen.

- Test parameters tailored to your needs are available.

- The operations of the 2 stations are separate from each other.

- Related parameters in real-time are displayed on the screen for monitoring.

- It can accept different sizes of spectacle samples.

- Equipped with a plastic cover to protect operators throughout the test.

- An emergency switch is available.

- High durability and low noise.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amade Tech sales engineers will respond within one working day.