The Origin of IP Codes

In the early 20th century, with the widespread use of electrical equipment (especially motors, switches, and lighting fixtures) in industrial, mining, construction, and outdoor environments, a pressing issue arose: how to clearly and uniformly describe and verify the protective capabilities of equipment enclosures against solid foreign objects (such as dust and tools) and moisture intrusion?

Prior to this, manufacturers used their own vague terminology, leading to various negative problems, such as:

- Confusion and misunderstanding: Buyers could not accurately compare the protective performance of different products.

- Safety hazards: Using inadequately protected equipment in hazardous environments (such as dusty, damp mines) could lead to malfunctions, short circuits, or even explosions.

- Trade barriers: Inconsistent national standards hindered international trade and technological exchange.

Therefore, an internationally recognized, objective, and testable coding system was needed to define protection levels.

The prototype of IP codes can be traced back to Germany. As an industrial powerhouse, Germany pioneered the DIN 40050 standard, establishing a systematic classification system for protection levels. This system was logically clear, using numbers to represent protection levels, laying the foundation for later international standards.

The International Electrotechnical Commission (IEC), as the world’s most important electrotechnical standards body, is dedicated to harmonizing national standards. Building upon the German DIN standard, the IEC first published IEC 60529 in 1976, titled “Degrees of Protection Provided by Enclosures (IP Codes)”. IEC 60529 provides a globally unified framework, specifying different protection levels and corresponding test methods. This standard was quickly adopted by countries around the world, including Europe, the United States, China, Japan, and South Korea, leading to the development of corresponding national standards.

Why Do the IP Codes Matter

Since 1976, IEC 60529 has undergone numerous revisions and improvements, but its core structure and logic have remained consistent, demonstrating the superiority of its design. The IP codes specified in this standard are widely accepted and adopted in countries and regions worldwide, illustrating its importance and universality. Specifically, they offer the following advantages:

- Becoming a universal language: IP codes have become a “universal language” for engineers, buyers, consumers, and even ordinary users to understand the environmental tolerance of products such as mobile phones, watches, lighting fixtures, and outdoor equipment.

- Ensuring safety and reliability: IP codes ensure safe and reliable operation of equipment under nominal environmental conditions, especially in harsh industrial environments and everyday outdoor use.

- Driving design and innovation: Clear rating targets encourage manufacturers to continuously innovate in enclosure design, sealing materials (such as silicone rings), and processes.

- Facilitating global trade: IP codes eliminate technical trade barriers caused by unclear protection descriptions.

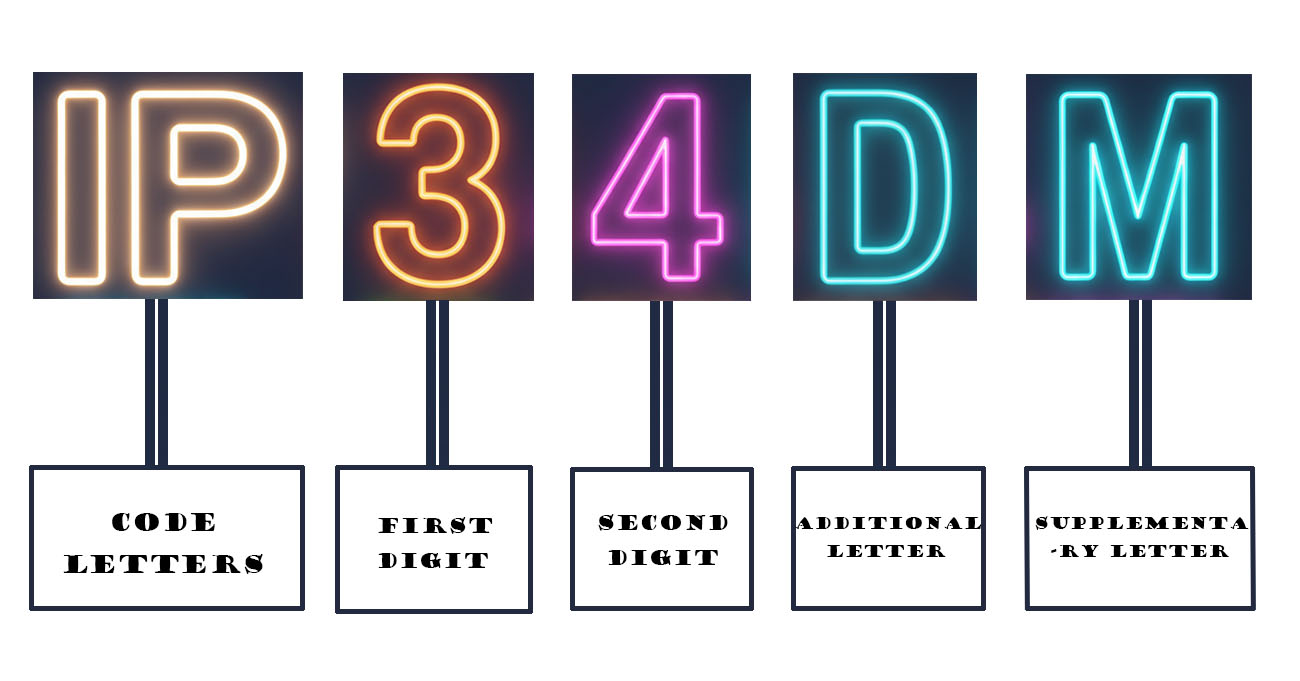

What Is An IP Code

IP stands for International Protection or Ingress Protection, a globally standardized rating system (standard number IEC 60529) developed by the International Electrotechnical Commission (IEC) to precisely define the protection provided by the enclosure of electrical equipment against the intrusion of solid foreign objects (including dust) and liquids (primarily water). It uses a simple format of “IP” followed by two core digits: the first digit (0-6) represents the level of protection against electric shock, foreign objects, and dust, ranging from “no protection” to “completely dustproof”; the second digit (0-9) represents the level of water resistance, ranging from “no protection” to “resistant to high-pressure, high-temperature water jets.” For example, the common “IP67” means the equipment is dustproof (completely prevents dust ingress) and can withstand brief immersion in water.

Furthermore, this code can be followed with additional letters (such as IPX5B) or supplementary letters to further specify the protection against approach to hazardous parts or specific test conditions.

The core value of IP codes lies in the fact that, through a set of unified and rigorous laboratory testing methods, they transform the originally vague claims of “waterproof” and “dustproof” into objective, comparable, and reliable technical indicators. This makes IP codes an authoritative and internationally recognized language for consumers to assess the environmental tolerance of devices (such as the robustness of mobile phones, watches, and outdoor lighting) and for engineers to design and select products.

Interpreting the First Digit in the IP Code

The first number of an IP code represents two meanings simultaneously: the enclosure provides protection against both human contact with hazardous parts and against the intrusion of solid foreign objects. If a digit is not required to be specified, it shall be replaced with an letter “X”.

- Degrees of Protection Against Access to Hazardous Parts Indicated by the First Digit

From the perspective of protecting hazardous parts (including hazardous live parts and hazardous mechanical parts), the first digit of an IP code can be any number from 0 to 6. Below, we will explain the specific meaning of each different numeral.

First digit | Meaning | Determination method |

0 | Non-protected | |

1 | The equipment enclosure is designed to prevent people from touching hazardous internal components with the back of a hand. | A 50 mm diameter steel ball is pushed against any openings of the equipment enclosure with a force of 50N ± 10% to approach the hazardous components inside, but it is blocked and could not pass through completely, leaving a sufficient safe distance between the iron ball and the hazardous parts. |

2 | The equipment enclosure is designed to prevent human fingers from touching the internal hazardous parts. | A simulated jointed metal finger with a diameter of 12 mm and a length of 80mm is inserted through any openings of the equipment enclosure with a force of 10N ± 10% to approach the hazardous components inside. The finger may pass through a hole up to 80 mm long, but it cannot make contact with the hazardous parts and leaves a sufficient safety distance. |

3 | The equipment enclosure is designed to prevent the user from touching the internal hazardous parts with a metal tool. | A 2.5 mm diameter rigid steel rod is pushed against any openings of the equipment enclosure with a force of 3N ± 10% to approach the hazardous parts inside, but it can’t pass through the opening. |

4 | The equipment enclosure is designed to prevent a person from touching the internal hazardous parts with a metal wire. | A 1.0 mm diameter steel rod is pushed against any openings of the equipment enclosure with a force of 1N ± 10% to approach the hazardous parts inside, but failing to penetrate the opening. |

5 | The same as that of the digit 4 | |

6 | The same as that of the digit 4 | |

- Degrees of Protection Against Solid Foreign Objects Indicated by the First Digit

From the perspective of protecting against solid foreign objects, the first digit of the IP code can also be any number from 0 to 6. Below, we will explain the specific meaning of each different numeral.

First digit | Meaning | Determination method |

0 | Non-protected | |

1 | The equipment enclosure is designed to prevent solid foreign objects with a diameter of 50 mm or more from fully penetrating the enclosure. | A 50 mm diameter steel ball is pushed against any openings of the enclosure with a specified force of 50N ± 10%, and the ball should not be able to completely penetrate the opening. |

2 | The equipment enclosure is designed to prevent solid foreign objects with a diameter of 12.5 mm or greater from fully penetrating the enclosure. | A small steel ball with a diameter of 12.5 mm is pushed against any openings of the enclosure with a specified force of 30N ± 10%, and the ball should not be able to completely penetrate the opening. |

3 | The equipment enclosure is designed to prevent solid foreign objects with a diameter of 2.5 mm or greater from penetrating the enclosure. | A 2.5 mm diameter steel rod is pushed against any openings of the enclosure with a specified force of 3N ± 10%, and it is impossible to pass through the opening at all. |

4 | The equipment enclosure is designed to prevent solid foreign objects with a diameter of 1.0mm or greater from penetrating the enclosure. | A 1.0mm diameter steel rod is pushed against any openings of the enclosure with a specified force of 1N ± 10%, and it is impossible to pass through the opening at all. |

5 | The equipment enclosure is designed to be with the dust-protected function. | The equipment is exposed to a dust chamber filled with suspended talcum powder for the specified period of time. A certain amount of dust is allowed to enter the equipment through the casing, but the amount must not be so large as to interfere with the normal operation of the equipment or impair its safety. |

6 | The equipment enclosure is designed to be with the dust-tight function. | The equipment with pressure difference inside and outside is exposed to a dust chamber filled with suspended talcum powder for the specified period of time. No dust is allowed to enter the equipment through the casing. |

- Testing Instruments Involved in the First Digit in the IP Code

Instrument name | Picture | Applicable IP code | Testing protection against access to hazardous parts | Testing protection against solid foreign objects | Remark |

50 mm dia. test sphere |

| IP1X | available | available | ; |

Jointed test finger | IP2X | available | |||

12.5 mm dia test sphere | IP2X | available | |||

2.5 mm dia test rod | IP3X | available | available | ||

1.0 mm dia. test wire |

| IP4X | available | available | |

1.0 mm dia. test wire | IP5X/IP6X | available | |||

Dust chamber with or without underpressure | IP5X | available | ; | ||

Dust chamber with underpressure | IP6X | available |

Interpreting the Second Digit in the IP Code

The second digit of an IP code indicates the degree of protection provided by enclosures with respect to harmful effects on the equipment due to water ingress. If the sample enclosure does not specify a corresponding level of protection, an “X” is used instead.

- Degrees of Protection Against Ingress of Water Indicated by the Second Digit

The second digit in the IP code can be any number from 0 to 9. Below, we will explain the specific meaning of each different numeral.

First digit | Meaning | Determination method |

0 | Non-protected | |

1 | The equipment enclosure is designed to prevent vertically falling raindrops from entering the interior. | Exposing the sample to simulated vertical rain for a specified period of time, after which no harmful effects are observed on the sample. |

2 | The equipment enclosure is designed to prevent vertically falling raindrops from entering the interior when the enclosure is tilted. | Exposing the sample at a 15° along a vertical line to simulated vertical rain for a specified period of time, after which no harmful effects are observed on the sample. |

3 | The equipment enclosure is designed to has the ability to protect against water spray. | Spraying water at a specified flow rate centering the vertical line across a 120-degree arc onto the sample for a specified time, after which no harmful effects are observed on the sample. |

4 | The equipment enclosure is designed to has the ability to protect against water splash. | Spraying water at a specified flow rate from any direction onto the sample for a specified time, after which no harmful effects are observed on the sample. |

5 | The equipment enclosure is designed to has the ability to protect against water jets. | Spraying a water jet of a specified flow rate at the sample from any direction for a specified duration, after which no harmful effects are observed on the sample. |

6 | The equipment enclosure is designed to has the ability to protect against strong water jets. | Projecting a high-speed water jet of a specified flow rate at the sample from any direction for a specified duration, after which no harmful effects are observed on the sample. |

7 | The equipment enclosure is designed to has the ability to protect against temporary water immersion. | Immersing the sample in water at a specified depth for 30 minutes. Even if a certain amount of water enters the sample, it will not have a harmful effect on the sample. |

8 | The equipment enclosure is designed to has the ability to protect against continuous water immersion. | Immersing the sample in water to a specified depth for a specified time. The specific depth and duration of the immersion test must be agreed upon by the equipment manufacturer and user, and must be more stringent than the IPX7 test conditions. Even if a certain amount of water enters the sample, it will not have a harmful effect on the sample. |

9 | The equipment enclosure is designed to has the ability to protect against high temperature and high pressure water jets. | Spraying a high-pressure stream of water at 80 ± 5 degrees Celsius onto the sample from any direction for a specified period of time, without causing any adverse. |

- Testing Instruments Involved in the Second Digit in the IP Code

Instrument name | Picture | Applicable IP code | Testing the degrees of protection against ingress of water | Remark |

Water drip test equipment |

| IPX1 | available | ; |

Water drip test equipment | IPX2 | available | ; | |

Water spray test equipment | IPX3 | available | ; | |

Water splash test equipment | IPX4 | available | ; | |

Water jet test equipment | IPX5 | available | ; | |

Powerful water jet test equipment | IP5X6 | available | ; | |

Temporary immersion test equipment | IPX7 | available | ; | |

Continuous immersion test equipment |

| IPX8 | available | ; |

High temperature and pressure test equipment | IPX9 | available | ; |

Interpreting the “Additional letter” in the IP Code

“Additional letter” indicates the degrees of protection of persons against access to hazardous parts. It is located in the third digit of the IP code. There are four protection levels: A, B, C, and D, but these are optional and not mandatory to appear in the IP code. An additional letter is only required in the IP code when either of the following two situations occurs: First, if the actual level of protection against hazardous parts is higher than the level indicated by the first digit of the IP code. Second, if the sample only provides protection against hazardous parts, and the first digit of the IP code is replaced by an X.

Additional letter | Meaning | Determination method | Instrument involved |

A | Protected against access with the back of the hand | A 50 mm diameter steel ball is pushed against any openings of the enclosure with a force of 50N±10% to approach the hazardous components inside, ensuring that it cannot reach them and that there is a sufficient safe distance between the metal ball and the hazardous parts. | The instruments used for the four protection test ratings in the Additional Letters and the instruments used for protection against access to hazardous parts indicated by the first digit (IP1X, IP2X, IP3X, IP4X) of the IP code are interchangeable. |

B | Protected against access with a finger | A simulated metal finger, 12mm in diameter and 80mm in length, is used to approach a hazardous component inside the equipment through any openings. The finger is allowed to enter the equipment up to 80mm in length, but there must be no contact between the finger and the hazardous parts, and a sufficient safety distance must be maintained. | |

C | Protected against access with a tool | A 100mm long, 2.5mm diameter steel rod is pushed against any openings of the enclosure to approach the hazardous parts indie. The access rod may penetrate to its full length, but the stop face shall not pass through the opening, and a sufficient safety distance between the rod tip and the hazardous parts is maintained. | |

D | Protected against access with a wire | A 100mm long, 1.0mm diameter steel rod is pushed against any openings of the enclosure to approach the hazardous parts indie. The access rod may penetrate to its full length, but the stop face shall not pass through the opening, and a sufficient safety distance between the rod tip and the hazardous parts is maintained. |

Interpreting the “Supplementary Letter” in the IP Code

“Supplementary letters” may appear as the third or fourth digit in the IP code. However, they are not commonly used and are optional; their presence in the IP code is not mandatory. Such special cases should comply with the requirements of this basic security standard, and product standards should clearly specify the additional procedures to be performed in tests of this category.

Supplementary letter | Meaning |

H | High-voltage apparatus |

M | It has been tested whether water ingress would have harmful effects when the movable parts of the equipment (such as the rotor of rotating machinery) are in motion. |

S | It has been tested whether water ingress would have harmful effects when the movable parts of the equipment (such as the rotor of rotating machinery) are stationary. |

W | Suitable for use under specific weather conditions, and has additional protective features or processes. |

Interpreting a Complete IP Code

A complete IP Code consists of code letters of IP, and at least two digits (either numbers or the letter X). The third and fourth digits are not required. Here’s an example of an IP address with four digits:

The Numeral 3 means the enclosure protects persons against access to hazardous parts with a tool. In addition, it protects the equipment inside the enclosure against ingress of solid foreign objects have a diameter of 2.5 mm and greater.

The Numeral 4 means the enclosure protects the equipment inside the enclosure against ingress of splashing water.

The Letter D means the enclosure protects persons handling tools have a diameter of 1.0 mm and greater and a length not exceeding 100 mm against access to hazardous parts (the tool may penetrate the enclosure up to its full length)

The Letter M means the enclosure is tested for protection against harmful effects due to the ingress of water when all the parts of the equipment are in motion.

Summary of Common IP Ratings

IP Code Rating | Brief description |

IP00 | Non-protection is provided |

IPX1 | The equipment is protected against vertically falling water drops. |

IPX2 | The equipment is protected against vertically falling water drops when it is tilted up to 15°. |

IPX3 | The equipment is protected against spraying water. |

IPX4 | The equipment is protected against splashing water. |

IPX5 | The equipment is protected against water jets. |

IPX6 | The equipment is protected against powerful water jets. |

IPX7 | The equipment is protected against the effects of temporary immersion in water |

IPX8 | The equipment is protected against the effects of continuous immersion in water |

IPX9 | The equipment is protected against high pressure and high temperature water jets |

IP1X | The equipment is protected against access to hazardous parts with the back of a hand, and solid foreign objects of 50mm and greater in diameter. |

IP11 | The equipment is protected against access to hazardous parts with the back of a hand, and solid foreign objects of 50mm and greater in diameter. In addition, it is protected against vertically falling water drops. |

IP12 | The equipment is protected against access to hazardous parts with the back of a hand, and solid foreign objects of 50mm and greater in diameter. In addition, it is protected against vertically falling water drops when the enclosure is tilted up to 15°. |

IP13 | The equipment is protected against access to hazardous parts with the back of a hand, and solid foreign objects of 50mm and greater in diameter. In addition, it is protected against spraying water. |

IP14 | The equipment is protected against access to hazardous parts with the back of a hand, and solid foreign objects of 50mm and greater in diameter. In addition, it is protected against splashing water. |

IP15 | The equipment is protected against access to hazardous parts with the back of a hand, and solid foreign objects of 50mm and greater in diameter. In addition, it is protected against water jets. |

IP16 | The equipment is protected against access to hazardous parts with the back of a hand, and solid foreign objects of 50mm and greater in diameter. In addition, it is protected against powerful water jets. |

IP17 | The equipment is protected against access to hazardous parts with the back of a hand, and solid foreign objects of 50mm and greater in diameter. In addition, it is protected against the effects of temporary immersion in water. |

IP18 | The equipment is protected against access to hazardous parts with the back of a hand, and solid foreign objects of 50mm and greater in diameter. In addition, it is protected against the effects of continuous immersion in water. |

IP19 | The equipment is protected against access to hazardous parts with the back of a hand, and solid foreign objects of 50mm and greater in diameter. In addition, it is protected against high pressure and high temperature water jets |

IP2X | The equipment is protected against access to hazardous parts with a finger, and solid foreign objects of 12.5mm and greater in diameter. |

IP21 | The enclosure is protected against access to hazardous parts with a finger, and solid foreign objects of 12.5mm and greater in diameter. In addition, it is protected against vertically falling water drops. |

IP22 | The equipment is protected against access to hazardous parts with a finger, and solid foreign objects of 12.5mm and greater in diameter. In addition, it is protected against vertically falling water drops when the enclosure is tilted up to 15°. |

IP23 | The equipment is protected against access to hazardous parts with a finger, and solid foreign objects of 12.5mm and greater in diameter. In addition, it is protected against spraying water. |

IP24 | The equipment is protected against access to hazardous parts with a finger, and solid foreign objects of 12.5mm and greater in diameter. In addition, it is protected against splashing water. |

IP25 | The equipment is protected against access to hazardous parts with a finger, and solid foreign objects of 12.5mm and greater in diameter. In addition, it is protected against water jets. |

IP26 | The equipment is protected against access to hazardous parts with a finger, and solid foreign objects of 12.5mm and greater in diameter. In addition, it is protected against strong water jets. |

IP27 | The equipment is protected against access to hazardous parts with a finger, and solid foreign objects of 12.5mm and greater in diameter. In addition, it is protected against the effects of temporary immersion in water. |

IP28 | The equipment is protected against access to hazardous parts with a finger, and solid foreign objects of 12.5mm and greater in diameter. In addition, it is protected against the effects of continuous immersion in water. |

IP29 | The equipment is protected against access to hazardous parts with a finger, and solid foreign objects of 12.5mm and greater in diameter. In addition, it is protected against high pressure and high temperature water jets. |

IP3X | The equipment is protected against access to hazardous parts with a tool, and solid foreign objects of 2.5mm and greater in diameter. |

IP31 | The equipment is protected against access to hazardous parts with a tool, and solid foreign objects of 2.5mm and greater in diameter. In addition, it is protected against vertically falling water drops. |

IP32 | The equipment is protected against access to hazardous parts with a tool, and solid foreign objects of 2.5mm and greater in diameter. In addition, it is protected against vertically falling water drops when it is tilted up to 15°. |

IP33 | The equipment is protected against access to hazardous parts with a tool, and solid foreign objects of 2.5mm and greater in diameter. In addition, it is protected against spraying water. |

IP34 | The equipment is protected against access to hazardous parts with a tool, and solid foreign objects of 2.5mm and greater in diameter. In addition, it is protected against splashing water. |

IP35 | The equipment is protected against access to hazardous parts with a tool, and solid foreign objects of 2.5mm and greater in diameter. In addition, it is protected against water jets. |

IP36 | The equipment is protected against access to hazardous parts with a tool, and solid foreign objects of 2.5mm and greater in diameter. In addition, it is protected against strong water jets. |

IP37 | The equipment is protected against access to hazardous parts with a tool, and solid foreign objects of 2.5mm and greater in diameter. In addition, it is protected against the effects of temporary immersion in water. |

IP38 | The equipment is protected against access to hazardous parts with a tool, and solid foreign objects of 2.5mm and greater in diameter. In addition, it is protected against the effects of continuous immersion in water. |

IP39 | The equipment is protected against access to hazardous parts with a tool, and solid foreign objects of 2.5mm and greater in diameter. In addition, it is protected against high pressure and high temperature water jets. |

IP4X | The equipment is protected against access to hazardous parts with a wire, and solid foreign objects of 1.0mm and greater in diameter. |

IP41 | The equipment is protected against access to hazardous parts with a wire, and solid foreign objects of 1.0mm and greater in diameter. In addition, it is protected against vertically falling water drops. |

IP42 | The equipment is protected against access to hazardous parts with a wire, and solid foreign objects of 1.0mm and greater in diameter. In addition, it is protected against vertically falling water drops when it is tilted up to 15°. |

IP43 | The equipment is protected against access to hazardous parts with a wire, and solid foreign objects of 1.0mm and greater in diameter. In addition, it is protected against spraying water. |

IP44 | The equipment is protected against access to hazardous parts with a wire, and solid foreign objects of 1.0 mm and greater in diameter. In addition, it is protected against splashing water. |

IP45 | The equipment is protected against access to hazardous parts with a wire, and solid foreign objects of 1.0mm and greater in diameter. In addition, it is protected against water jets. |

IP46 | The equipment is protected against access to hazardous parts with a wire, and solid foreign objects of 1.0mm and greater in diameter. In addition, it is protected against strong water jets. |

IP47 | The equipment is protected against access to hazardous parts with a wire, and solid foreign objects of 1.0mm and greater in diameter. In addition, it is protected against the effects of temporary immersion in water. |

IP48 | The equipment is protected against access to hazardous parts with a wire, and solid foreign objects of 1.0mm and greater in diameter. In addition, it is protected against the effects of continuous immersion in water. |

IP49 | The equipment is protected against access to hazardous parts with a wire, and solid foreign objects of 1.0mm and greater in diameter. In addition, it is protected against high pressure and high temperature water jets. |

IP5X | The equipment is protected against access to hazardous parts with a wire, and dust-protected. |

IP51 | The equipment is protected against access to hazardous parts with a wire, and dust protected. In addition, it is protected against vertically falling water drops. |

IP52 | The equipment is protected against access to hazardous parts with a wire, and dust-protected. In addition, it is protected against vertically falling water drops when it is tilted up to 15°. |

IP53 | The equipment is protected against access to hazardous parts with a wire, and dust-protected. In addition, it is protected against spraying water. |

IP54 | The equipment is protected against access to hazardous parts with a wire, and dust-protected. In addition, it is protected against splashing water |

IP55 | The equipment is protected against access to hazardous parts with a wire, and dust-protected. In addition, it is protected against water jets. |

IP56 | The equipment is protected against access to hazardous parts with a wire, and dust-protected. In addition, it is protected against strong water jets. |

IP57 | The equipment is protected against access to hazardous parts with a wire, and dust-protected. In addition, it is protected against the effects of temporary immersion in water. |

IP58 | The equipment is protected against access to hazardous parts with a wire, and dust-protected. In addition, it is protected against the effects of continuous immersion in water. |

IP59 | The equipment is protected against access to hazardous parts with a wire, and dust-protected. In addition, it is protected against high pressure and high temperature water jets. |

IP6X | The equipment is protected against access to hazardous parts with a wire, and dust-tight. |

IP61 | The equipment is protected against access to hazardous parts with a wire, and dust-tight. In addition, it is protected against vertically falling water drops. |

IP62 | The equipment is protected against access to hazardous parts with a wire, and dust-tight. In addition, it is protected against vertically falling water drops when it is tilted up to 15°. |

IP63 | The equipment is protected against access to hazardous parts with a wire, and dust-tight. In addition, it is protected against spraying water. |

IP64 | The equipment is protected against access to hazardous parts with a wire, and dust-tight. In addition, it is protected against splashing water. |

IP65 | The equipment is protected against access to hazardous parts with a wire, and dust-tight. In addition, it is protected against water jets. |

IP66 | The equipment is protected against access to hazardous parts with a wire, and dust-tight. In addition, it is protected against strong water jets. |

IP67 | The equipment is protected against access to hazardous parts with a wire, and dust-tight. In addition, it is protected against the effects of temporary immersion in water. |

IP68 | The equipment is protected against access to hazardous parts with a wire, and dust-tight. In addition, it is protected against the effects of continuous immersion in water. |

IP69 | The equipment is protected against access to hazardous parts with a wire, and dust-tight. In addition, it is protected against high pressure and high temperature water jets. |