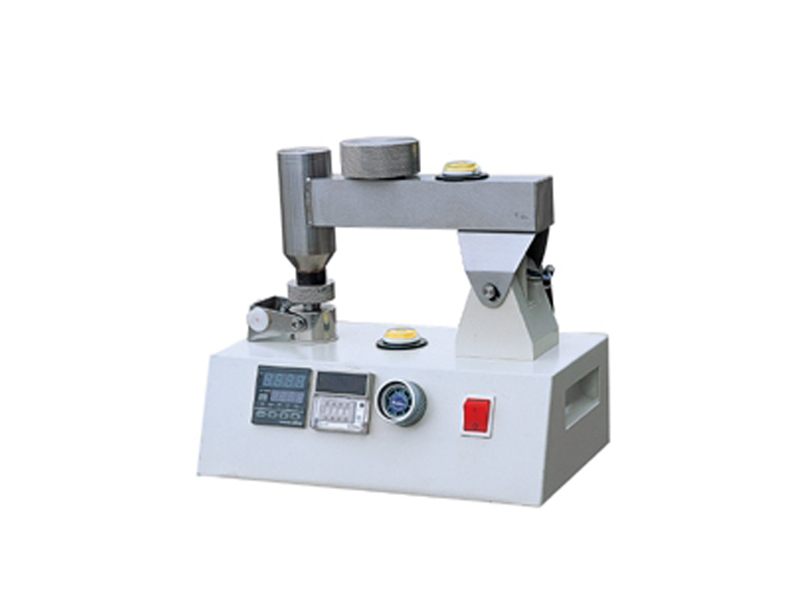

Safety Shoes Compression & Puncture Resistance Tester China Manufacturer

Safety Shoes Compression and Penetration Resistance Tester is a footwear testing device with dual functions. It can be used to determine either the resistance of the safety shoe’s toecap to compression or the resistance of the safety shoe’s sole to penetration under specified conditions.

Test Standards

GB/T 20991-5.5, 5.8, GB/T12017, ISO 20344-5.5, 5.8, AS/NZS2210.2-5.5, 5.8, EN12568-5.23, 7.2, EN 344-1-5.4, 5.6, EN 388-6.4, BS-953-5, ASTM F2412-6, 11, ASTM F2413-5.2, 5.7, etc.

Main Technical Parameters

| Model | AT-F3020 |

| Compression Test | Compress force:

EN: (15 ± 0.1) kN ASTM: 5000 lbf (22241N) Force resolution: 1 / 100,000 Force accuracy: 0.5% Force max. capacity: 20 kN Compress speed: EN: (5 ± 2) mm / min ASTM: 50 lbs / sec Compress steel plate hardness: 60 HRC |

| Nail Penetration Test | Ø Penetration speed: (10 ± 3) mm / min

Tip: diameter (4.5 ± 0.05) mm Clamp hole dia.: 25 mm ASTM F2412 2413: Compress head dia.: 76.2 mm (3 inches) Compress plate width: 152.4 mm Displacement resolution: 0.01 mm Ø Constant speed & specified penetration force Speed: (10 ± 3) mm / min Ø When the applied force reached 1.1 kN (1.2 KN), the compression stopped, and then observe specimen within 10 s |

| Force Unit Switch | Kgf, N, lbf, g, ton,Mpa |

| Machine Transmission Mode | Servo motor drive, synchronous wheel and precision ball screw drive |

| Stop Mode | Overload stop, emergency stop button, specimen damage automatic stop, Upper&Lower limit set automatic stop, automatic reset function |

| Power Supply | 1 phase, AC 220 ± 10%, 50 / 60 Hz |

| Dimension | 82´72´77 cm |

| Weight | 160 kg |

| Standard Accessories | Compression plate 1 pc

Lower clamp for compression test 1 set Test nail 1 pc Lower clamp for puncture test (Inner diameter 25mm) 1 set Power line 1 pc |

| Optional Accessories | EN388 Lower clamp for puncture test (Inner diameter 20 mm) |

Safety Shoes Compression and Puncture Resistance Tester Features

- It is mainly made of high-quality stainless steel and cold-rolled steel to ensure enough rigidity and durability.

- Both the compression test and the puncture test can be performed on this machine. Users only need to replace the fixture to complete the two tests.

- In order to meet a variety of test standards, We have 20 KN and 50 KN for users to choose from.

- Configured with the microcomputer and touch screen control to make the operation more convenient and result more accurate.

- Customers can choose professional testing software, which can observe the dynamic change curve of the force-time values.

- Test results can be exported and edited at will.

- Equipped with an emergency stop button to make the test more convenient and safer.

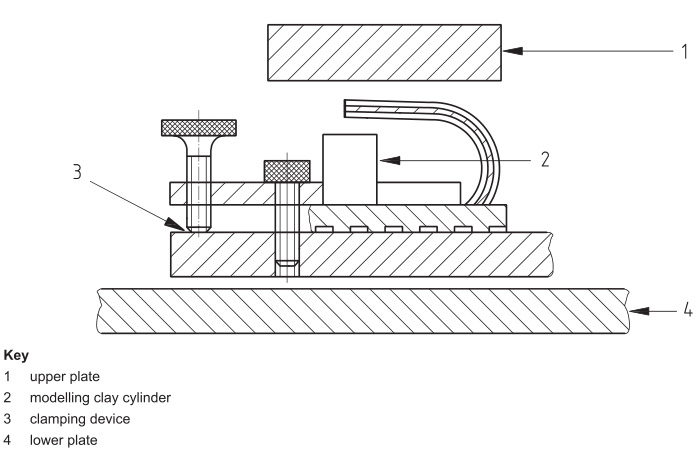

Compression Resistance Test Procedure

- Place a cylinder on one of its ends inside the specimen.

- Place the test piece in the clamping device and adjust it.

- Position the clamping device and test piece between the plates of the compression machine and compress the test piece until the load of 15 ± 0.1 kN for safety shoe has been reached.

- Reduce the load, remove the cylinder, using a measuring device to measure the lowest height to which the cylinder has been compressed to the nearest 0.5mm. This value is the compression clearance.

The above is just for reference. Please strictly follow the procedure of the applied standard to carry out the test when you get this testing machine.

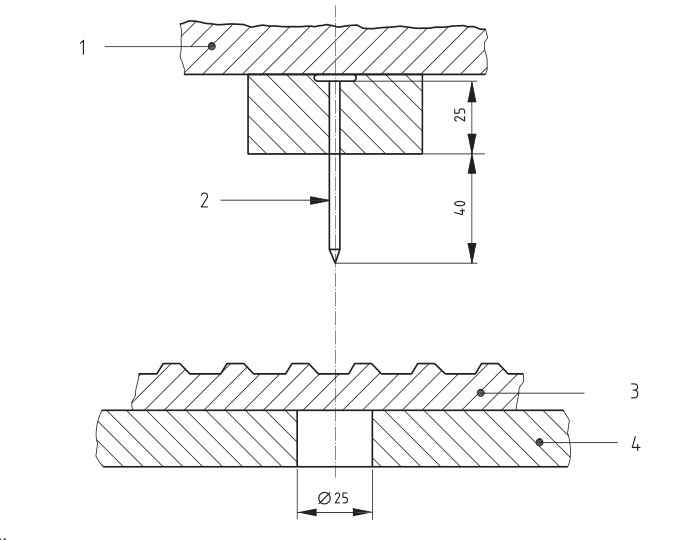

Penetration Resistance Test Procedure

- Place the specimen on the plate in such a way that the steel nail can puncture it across the bottom.

- Press the nail against the sole at a velocity of 10 ± 3 mm / minute until the point has been punctured fully and measure the maximum force.

- Conduct the test at 4 different points on the sole unit with a minimum distance of 30 mm between any 2 points and a minimum of 10 mm from the edge of the insole (for cleated soles, perform the test between cleats. 2 of the 4 measurements shall be done at a distance of 10 mm to 15 mm from the line represented by the feather edge of the last).

- The minimum value of the individual measurements is regarded as the test result.

The above is just for reference. Please strictly follow the procedure of the applied standard to carry out the test when you get this testing machine.

Send an Inquiry

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amadetech sales specialists will respond within one working day.