IPX1/2 Rain Test Chamber Supplier & Manufacturer

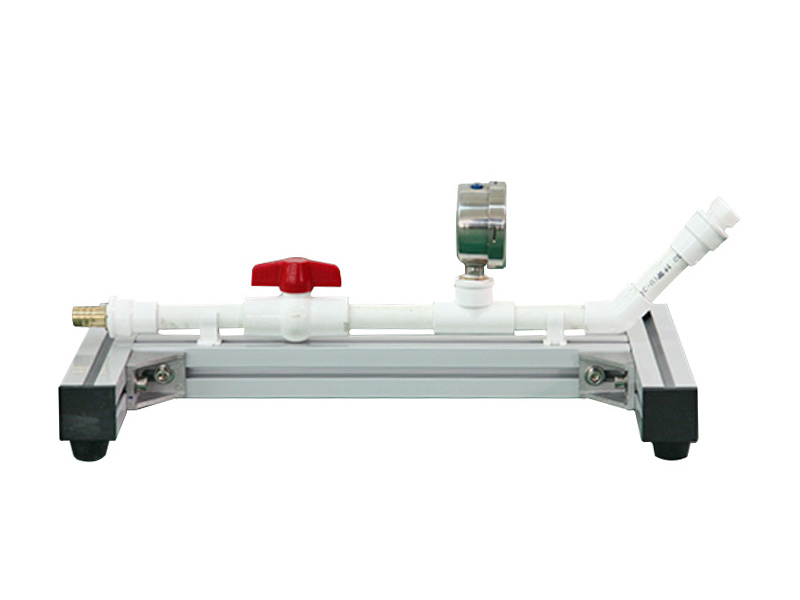

IPX1/2 Drip Test Equipment is designed to simulate vertically falling water drops onto a horizontal sample enclosure, or a sample enclosure tilted up to 15°, to determine basic waterproof performance in compliance with IEC 60529 standard.

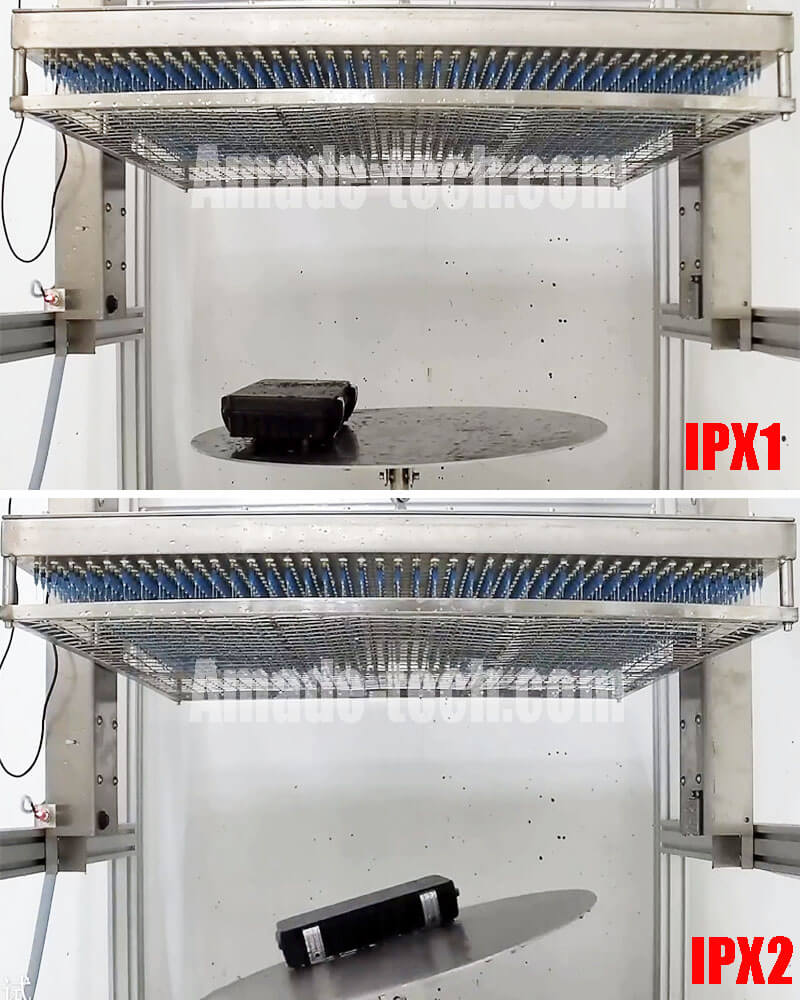

Most laboratories prefer our box-type rain test chamber for its water-saving and ease of use in water Ingress Protection (IP) rating tests. The inner chamber is made of 304 stainless steel, and it features a high-quality drip box at the ceiling. An array of needles is distributed in a 20 mm grid pattern at the bottom of the box to generate a uniform flow of droplets, accurately mimicking natural rainfall over the entire sample area. For enhanced operator safety, a durable protective mesh is positioned under the needles.

Sustainable Water Recycling in Testing

During testing, water droplets fall onto the specimen and collect in a tank below. A circulation motor continuously pumps water from the lower tank back to the upper drip box, enabling water recycling throughout the process. The addition of a pneumatic drainage feature of the drip box allows for easy maintenance by discharging residual water, preventing scale formation and extending the drip tester’s lifetime.

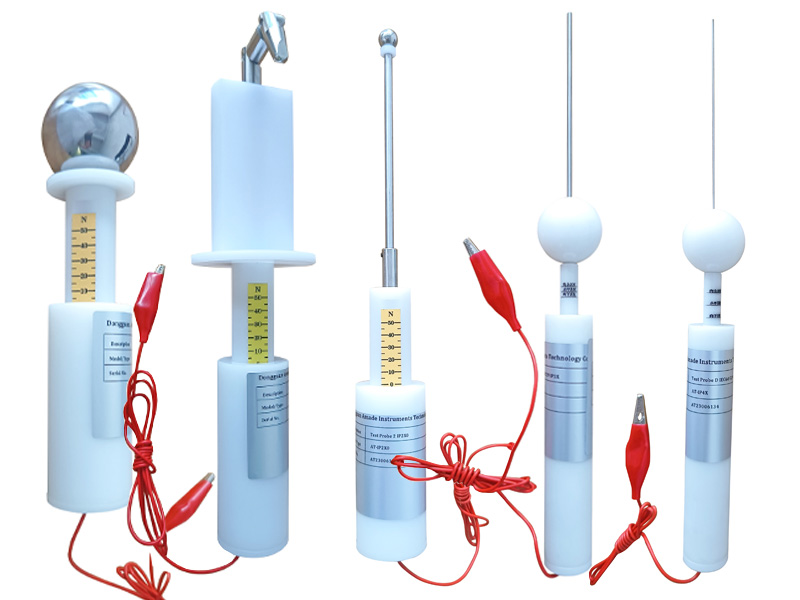

Drip needles

IPX1&IPX2 Tests-in-one | Intuitive HMI

AmadeTech’s advanced waterproof test equipment is equipped with a premium 304 stainless steel turntable. It supports precise eccentricity settings when mounting the sample and variable speed rotation (forward and reverse or alternately) to meet rigorous Ingress Protection (IP) standards. The turntable maintains a horizontal position for IPX1 drip tests and adjusts to a 15° tilt for IPX2 testing. The turntable’s height is adjustable to allow the distance between the needles and the specimen’s upper surface to achieve a maximum of 200 cm.

The machine is configured with a PLC and a 7″ touch screen for intuitive operation. Users simply select the desired IP rating and set parameters via the screen; once launched, the system carries out all operations automatically. To help you monitor the process, real-time parameters are displayed throughout the test. Once finished, the machine stops automatically and sounds an alarm.

IPX1 & IPX2 testing

IPX1-IPX6 combined test chamber

To optimize your laboratory’s efficiency, AmadeTech offers combined waterproof test chambers. We can integrate the hardware necessary for IPX1, IPX2, IPX3, IPX4, IPX5, IPX6, and IPX9 testing into a single, space-saving unit. This all-in-one solution reduces procurement costs and laboratory footprint without compromising on accuracy.

Contact AmadeTech today for a personalized quote on a custom IP waterproof testing solution tailored to your industry requirements.

For more water ingress protection testing devices, please click the below links:

IPX3 & 4 & 4K Spraying Test Equipment

IPX5 & 6 & 6K Jetting Test Equipment

IPX9K Water Spray Test Chamber

IPX1/2/3/4/5/6/9 Combined Test Equipment

Box-type rain test chamber

In addition to box-type drip test equipment, AmadeTech also supplies frame-type and wall-mounted IPX1/2 drip test equipment to accommodate larger or irregularly shaped samples. Their functions are the same, but they differ in structure, appearance, and cost. Please review some features below:

Frame-type Drip Test Equipment

- The frame is made of aluminum alloy.

- Suitable for working in the rain test room with waterproof function.

- The turntable assembly is flexible to move.

- Equipped with castors for moving the entire machine.

- Fitted with an electric hoist at the top.

- The drip pan can be raised and lowered automatically under control to achieve a spacing of 200 mm from the top of the specimen.

- Equipped with a separate controller featuring a touch screen.

- Supports energized testing of the specimen.

- Intelligent control of the test process is available.

- The sizes of the drip pan and frame are customizable.

- Supports pneumatic drainage.

Wall-mounted Drip Test Equipment

- The frame is made of aluminum alloy.

- Needs to be fixed against the wall.

- Takes up less space relative to other devices.

- Requires waterproofing at the test site.

- Fitted with an independent controller with a touch screen.

- Equipped with a photoelectric sensing device to allow the drip pan ascend and descend automatically under control to achieve a spacing of 200 mm from the top of the specimen.

- The turntable with casters is movable.

- Suitable for testing larger samples.

- Testing of energized specimens is available.

- Customizing the dimensions of the drip box and turntable is available.

- Supports pneumatic drainage.

If you want to learn more about IP testing equipment, please click HERE.

Wall-mounted test apparatus

Frame-type test apparatus

Conforming Test Standards

IEC60529, ISO 20653, IEC 60598-1, IEC 60068-2-18, IEC 60034-5, DIN 40050-9

Main Technical Specifications

Model | AT-C1005A2-400 | AT-C1005A2-600 | AT-C1005A-600 | AT-C1005A-800 | AT-C1005A-1000 | AT-C1005A-1200 | AT-C1005A1-600 | AT-C1005A1-800 | AT-C1005A1-1000 | AT-C1005A1-1200 | AT-C1005A1-1600 |

Equipment type | Box-type with an enclosed chamber | Wall-mounted | Frame-type | ||||||||

Drip area | (W) 400 X (D) 400 mm | (W) 600 X (D) 600 mm | (W) 600 X (D) 600 mm | (W) 800 X (D) 800 mm | (W) 1000 X (D) 1000 mm | (W) 1200 X (D) 1200 mm | (W) 600 X (D) 600 mm | (W) 800 X (D) 800 mm | (W) 1000 X (D) 1000 mm | (W) 1200 X (D) 1200 mm | (W) 1600 X (D) 1600 mm |

Turntable diameter | Dia. 300 mm | Dia. 400 mm | Dia. 400 mm | Dia. 600 mm | Dia. 600 mm | Dia. 800 mm | Dia. 400 mm | Dia. 600 mm | Dia. 800 mm | Dia. 1000 mm | Dia. 1000 mm |

Overall dimensions | (W) 1050 x (D) 850 x (H) 1550 mm | (W) 1250 x (D) 1050 x (H) 1750 mm | (W) 850 x (D) 950 x (H) 2450 mm | (W) 1050 x (D) 1150 x (H) 2450 mm | (W) 1250 x (D) 1350 x (H) 2450 mm | (W) 1450 x (D) 1550 x (H) 2450 mm | (W) 1150 x (D) 850 x (H) 2450 mm | (W) 1350 x (D) 1050 x (H) 2450 mm | (W) 1500 x (D) 1200 x (H) 2450 mm | (W) 1700 x (D) 1400 x (H) 2450 mm | (W) 1800 x (D) 1800 x (H) 2700 mm |

Spacing of drip holes | 20 x 20 mm | ||||||||||

Drip pinhole | Dia. 0.4 mm | ||||||||||

Drip pan height | Fixed | 800 ~ 1800 mm adjustable | |||||||||

Turntable height | Adjustable | 600 mm (fixed) | |||||||||

Turntable angle | 0° (horizontal) or 15° inclined adjustable | ||||||||||

Turntable loading capacity | Max. 50 kg | ||||||||||

Turntable rotating rate | 1 ~ 5 RPM adjustable | ||||||||||

Control mode | PLC + 7-inch touch screen | ||||||||||

Feature | Allows energized samples during the test | ||||||||||

IPX 1/2 Drip Test Equipment Features

- Dual-Function Testing: A versatile 2-in-1 system for both IPX1 and IPX2 waterproof testing.

- Durable Construction: Interior and exterior surfaces are made of 304 stainless steel and cold-roll steel sheets respectively.

- Customizable Sizes: Multiple chamber dimensions are available to meet various testing requirements.

- Replaceable Needles: Precision needles are designed for easy replacement when needed.

- Safety First: A protective plate is positioned under the needles to prevent accidental injury during operation.

- Observation Window: Equipped with a large inspection window for a clear view of the testing process.

- Clog Prevention: Includes a built-in water purification device to prevent needle blockage.

- Residual Drainage: The dripping tank features a pressurized system to fully discharge residual water.

- Water Recycling: Integrated with an automatic replenishment system to maintain continuous water circulation.

- Fully Adjustable: Water flow rate, test duration, and turntable speed are all user-adjustable.

- Smart Controls: A PLC and 7-inch touch screen provide intelligent control and real-time data display.

- Live Testing: Supports power-on testing for energized specimens during the water ingress test.

- Comprehensive Safety: Built-in protection against electrical leakage, water shortages, and short circuits.

- Easy Mobility: Heavy-duty castors at the base allow for effortless movement within the laboratory.

Frequently Asked Questions (FAQs)

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales specialists will respond within one working day.