We have already introduced the Determination of Flexing Resistance of Leathers conditioning temperature of (20±2)℃ and relative humidity of (65±2)℃ in last article, but although some leathers or coatings are able to pass the flexing test at ambient temperature, they can’t adapt to low temperature. Quality problems only can be found when the test is carried out under low temperature. Especially for the leathers which are produced and used in the cold areas, Determination of leather flexing resistance in low temperature is very necessary.

Sampling

Take a rectangle specimen measuring 70mm*45mm from a sample piece using a die cutter.

Instrument

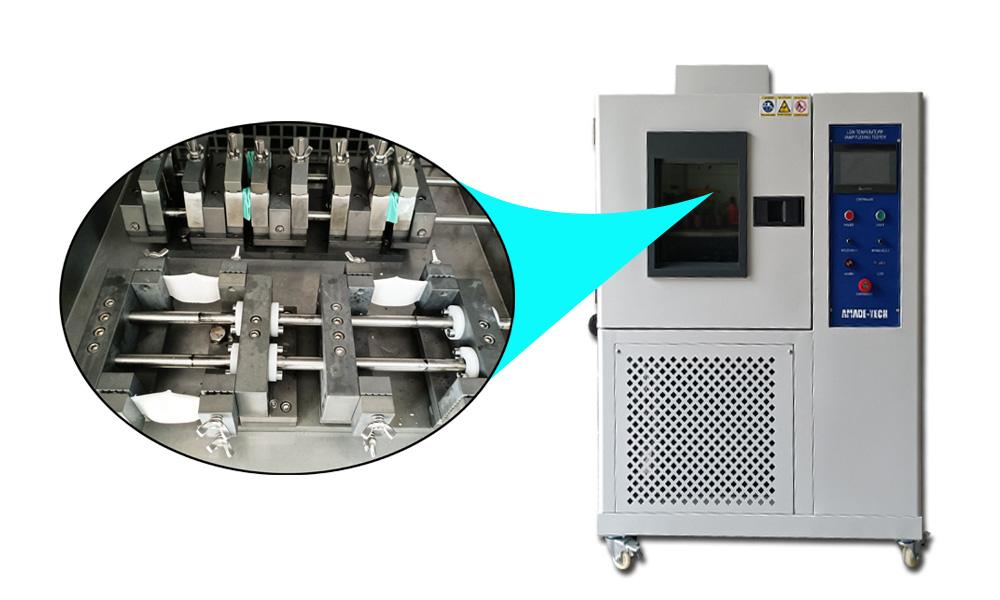

Pairs of flexing clamps composed of stationary clamps and moving clamps(the specifications are same as Bally Flexometer) are built in a Low Temperature Flexing Test Chamber featuring low temperature as low as -30℃ even -50℃(optional).

Besides, clamps can be custom in the light of the practical usage and specific standard cited to fulfill the test purpose, even one chamber can contain 2 sets of different clamps as below one.

Operation Steps

1.According to the testing method of flexing resistance test under standard atmospheric pressure, operators clamp the test piece into the testing machine.

2.Set the counter to “zero”, and connect to the power, then set the testing temperature of chamber to preset value of -20℃ or -30℃. The temperature of test piece is also dropped along with the cooling of chamber.

3.Start flexing when the preset temperature in the test chamber is reached, stop the test until the specified number of circles has been reached or have survived the stated period of bending If no cracking has occurred by that time, or test piece damage such as cracking has occurred. The change situation on the bending area is examined using a 6 times magnifying glass.

Test Results

1.Record the damage situation of test piece, such as cracking, decoating, fuzzing etc, and remark the number of circles.

2.Or without obvious failure within specified circles or period.

3.Write down the testing temperature.

Attention

1.Operator can remove the test piece for inspection in case of doubt about damage, but the position of being clamped shall be as identical as possible comparing with original one. If there is elongation occurring on the test piece during flex, don’t need to pull it straight.

2. It is best to reduce Temperature of Flexing apparatus in dry air because of large temperature gap between ambient temperature and temperature in the chamber. After measurement, temperature is restored in dry air to avoid the damage of instrument because of condensation water on the surface of the instrument arising from the temperature difference, moreover, the condensation water on the test piece also affects the determination result.

Amadetech is a professional leather testing Equipment supplier from China, offering various lab testing equipment with decent quality in competitive price. Please click our product page to learn more If you are interested in it, or directly reach us by [email protected].